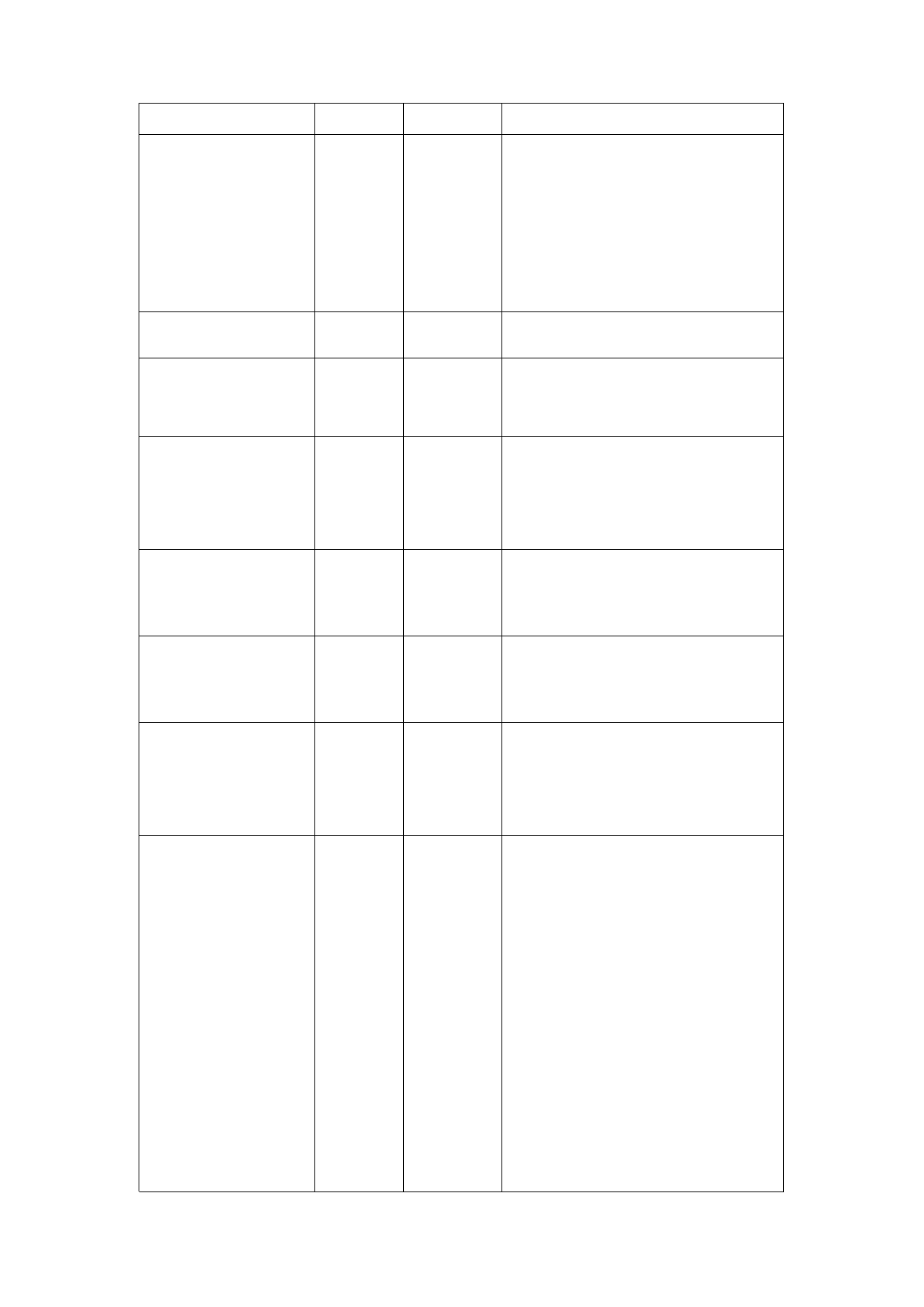

Table 9.2

The parameter name

Screw pitch

unit

mm

Upper speed

RPM gain

rpm

rpm/V

Number of pulses per

turn

Servo direction

Encoder direction

Servo type

Perforation touch ms

delay

scope

0.01-100

10-6000

10-2000

2-60000

Forward,

reverse

Forward,

reverse

0-6000

Parameter remarks

The distance that the screw turns

around to drive the nut moving, also

called the screw guide. the greater

the value is, the faster the Z axis

moves. It is recommended to use the

ball rod with 5-20mm guide.

Maximum speed of the servo motor

operates safely.

The servo motor speed of 1V voltage,

shall be consistent with the parameters

in the servo driver.

The number of pulses output by the

encoder per turn of the servo

motor, shall be consistent with

the parameters in the servo drive.

The rotation direction of the

servo motor, can be set to either

forward or reverse.

The direction of the encoder pulse

feedback, which can be set to

either forward or reverse.

Choose from Panasonic, Delta,

Yaskawa, Mitsubishi, Fuji,

Schneider, Dongyuan, Gaochuang,

Huichuan

Set the alarm detection

sensitivity of the touch plate (the

capacitor is zero at this time)

when perforation. The smaller the

value is, the more sensitive. Will

ignore alarm when set as 0. During

the perforation of the height

controller, the head touches the

plate due to the warping or slag.

If the delay time exceeds, the head

will automatically lift back to the

docking position and alarm.

Reasonable setting of this

parameter can effectively protect

the torch head during perforation

(reduce the value), or reduce the

false positives caused by the

reverse slag (increase the value).

110