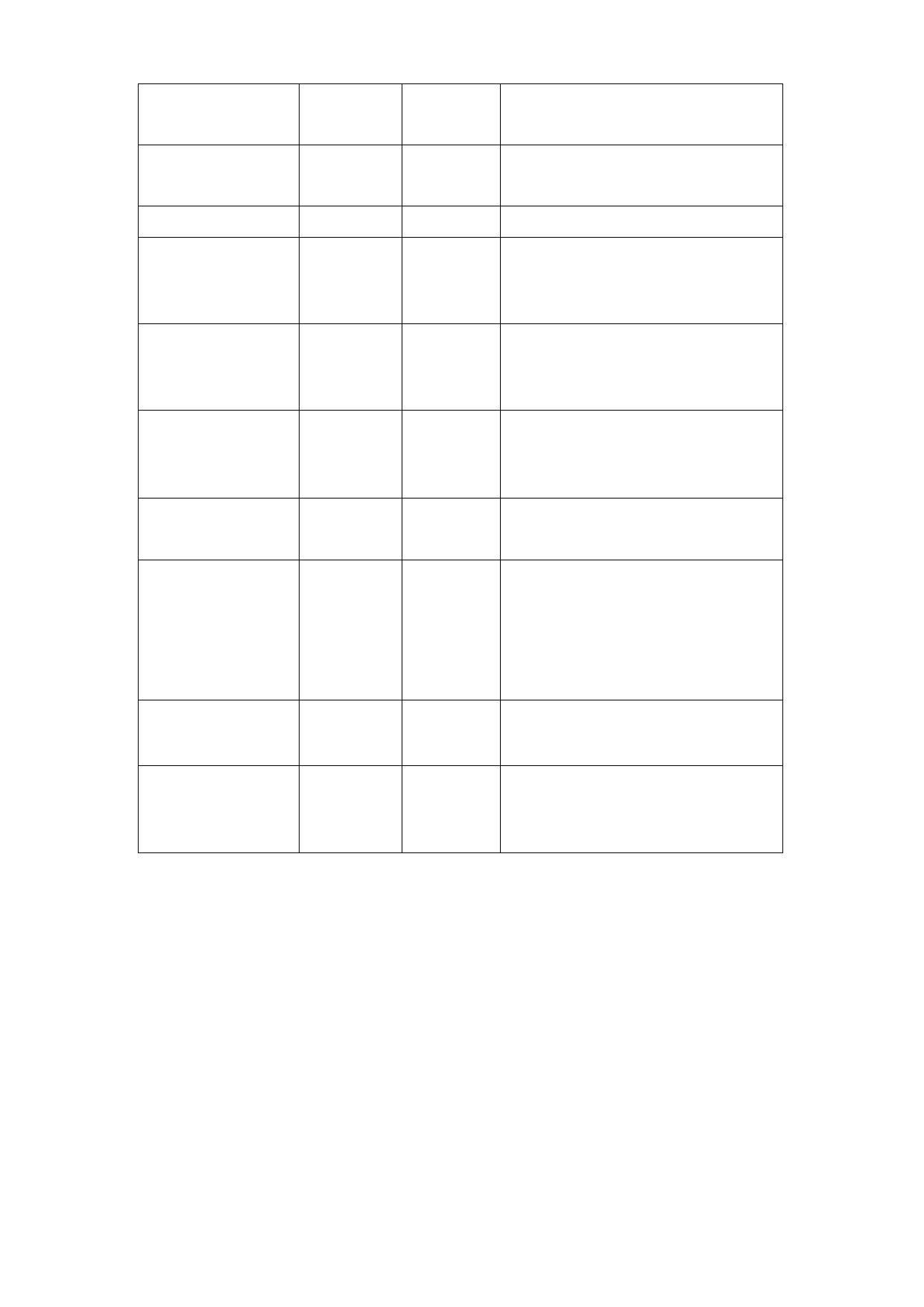

Advance open gas s

time

Opening time before move in place

Short dis not close mm

gas length

Burst peak power %

Burst pulse

Hz

frequency

Burst duty cycle %

Burst time

ms

Leap frog enable

Short dis not up

Micro connect used

fly cut

The gas is not closed within this

distance length

Percentage of the peak power

The number of times the signal

goes from high to low and returns

to high per second

Proportion of the power-on time

relative to the total time within

a pulse cycle

Press the click button to start

the time, after this time the

click will be closed

After enabling, will use frog

method to do empty walk.

When the empty move length is less

than the set value, the cutting

torch will go directly to the next

perforation point without lifting

the torch for processing

Microlinks use flight cutting

Start point

Starting point: default, center,

upper left, lower left, upper

right, lower right

Note: Kerf compensation (cutting torch radius value, only plate cutting can be set):

In order to ensure the dimensional accuracy of cutting parts, the user sets the kerf

compensation value according to the cut kerf width, and the system will automatically

generate a new cutting path to compensate the cut joint. The kerf value can be modified

before cutting a workpiece and is not allowed after cutting.

7. 3 Process parameters of the laser layer

Layer process parameters: all parameters used in laser cutting, involving cutting,

marking, evaporation, film, cutting, etc.

110