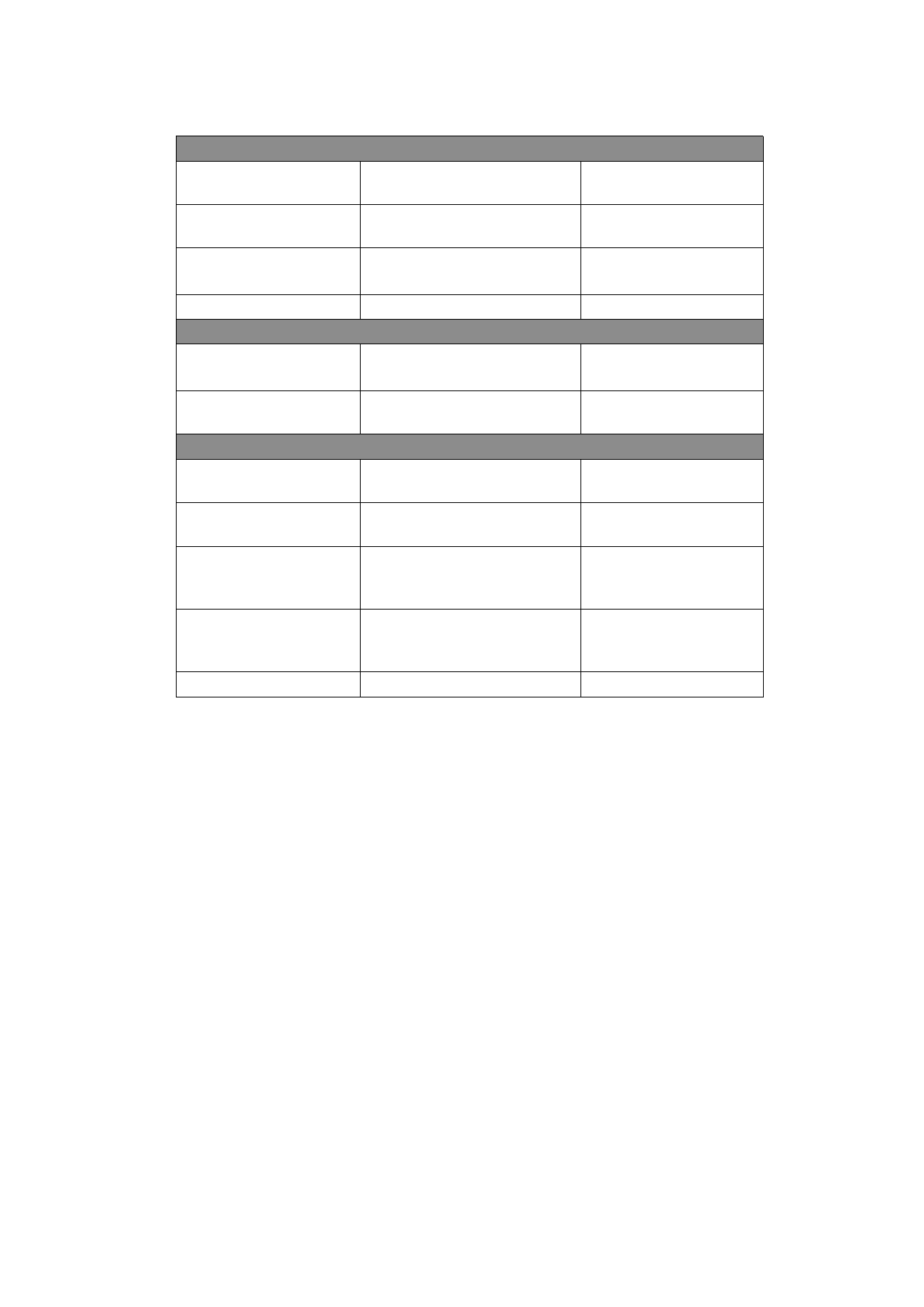

Table 1 3.2 Commonly used G, code table

G99

G92

G91 / G90

G20 / G21

Parameters: X / UY / VIJ

parameter:XY

No parameters

No parameters

Part option

parameters

Reference Point

Settings

Relative / absolute

coordinates

British / metric

G41 / G42

G40

No parameters

No parameters

Left / right kerf

compensation

Cancel kerf

compensation

G00

Parameters: X / UY / V Fast straight movement

(empty)

G01

Parameters: X / UY / V

Straight

cutting

G02

Parameters: X / UY / VIJ clockwise,

circular arc

cutting

G03

Parameters: X / UY / VIJ Counterclockwise

circular arc

cutting

G04

parameter:P

delay

1. G92 reference point setting

form:

G92[Xn][Yn]

Parameter meaning:

[Xn] [Yn] represents the absolute coordinates of the set reference point, and is also

the absolute coordinates of the machine tool back. If there is no parameter after G92, the

default reference point coordinate is (0,0). Generally, machine tools in (0,0) as the

reference point, this code can be omitted.

Note:

After the code is transferred, the reference point coordinates set by G92 will

be automatically saved. Before the new cut code, the reference point coordinate will

be valid, whether power off or not. After a new cut code is added, if the new code has

G92 instruction, the new reference point coordinate is the content after G92. If there

is no G92, the reference point is by default (0,0). A G92 can only appear once in a

code file.

example:

a.G92 X0 Y0