成都兴多维科技有限公司

Chengdu multidimensional robotization technology company

uniquely determined using a mechanical coordinate system. Every time

the power is turned off and restarted, the system needs to return the

machine to the mechanical zero point after the system stops.

3.1.2 Workpiece coordinate system

The workpiece coordinate system is used by the programmer during

programming. The programmer selects a known point on the workpiece as

the origin (also called the program origin) and creates a new

coordinate system called the workpiece coordinate system. The

workpiece coordinate system is also a set of right-handed coordinate

system. The origin of the workpiece coordinate system (ie the

workpiece origin) is determined relative to a certain point on the

workpiece, and can be floated relative to the mechanical coordinate

origin. The origin selection of the workpiece coordinate system

should be as simple as possible, such as simple programming, simple

size conversion, and small machining error.

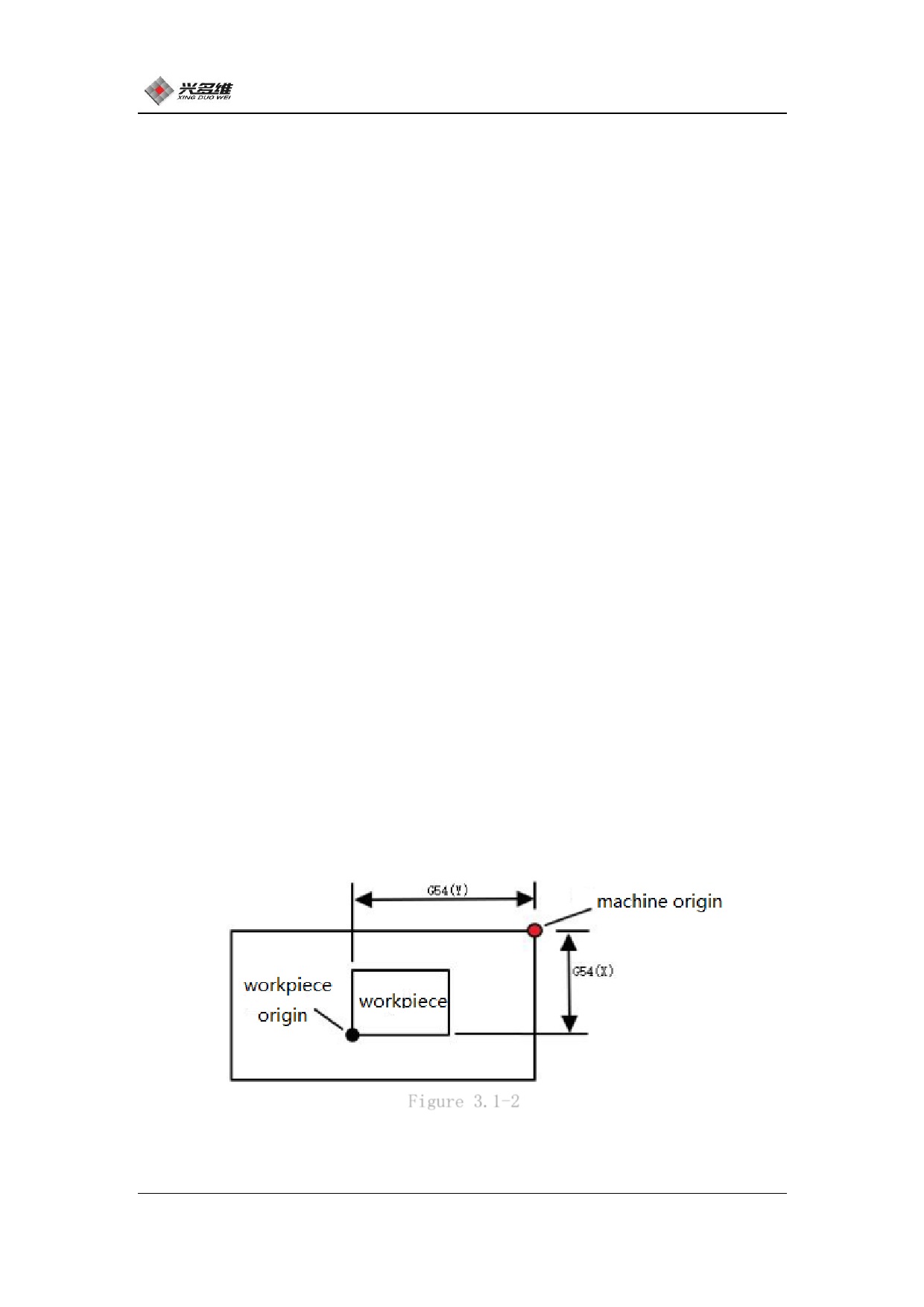

The workpiece offset corresponds to the coordinate system G54,

G55, G56, G57, G58, G59. When the system is turned on, the default

coordinate system is G54. The relationship between workpiece offset

and mechanical coordinate system is shown in Figure 3.1-2.:

Figure 3.1-2

25

兴于思 维至精