- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- EasyRoute-CNC-Router

- EasyRoute CNC Control Panel Manufacture Manual.pdf

- Page 95 of 114

Specialized Concentrated Focused

10. Driver

10.1.Driver Parameters

Driver parameters listed in this chapter can only make a machine tool motion normally, without

ensuring machining effects. To get a better machining result, you need to read through the servo driver

documentation of the corresponding brand and change the parameter setting according to the specific

machine tool.

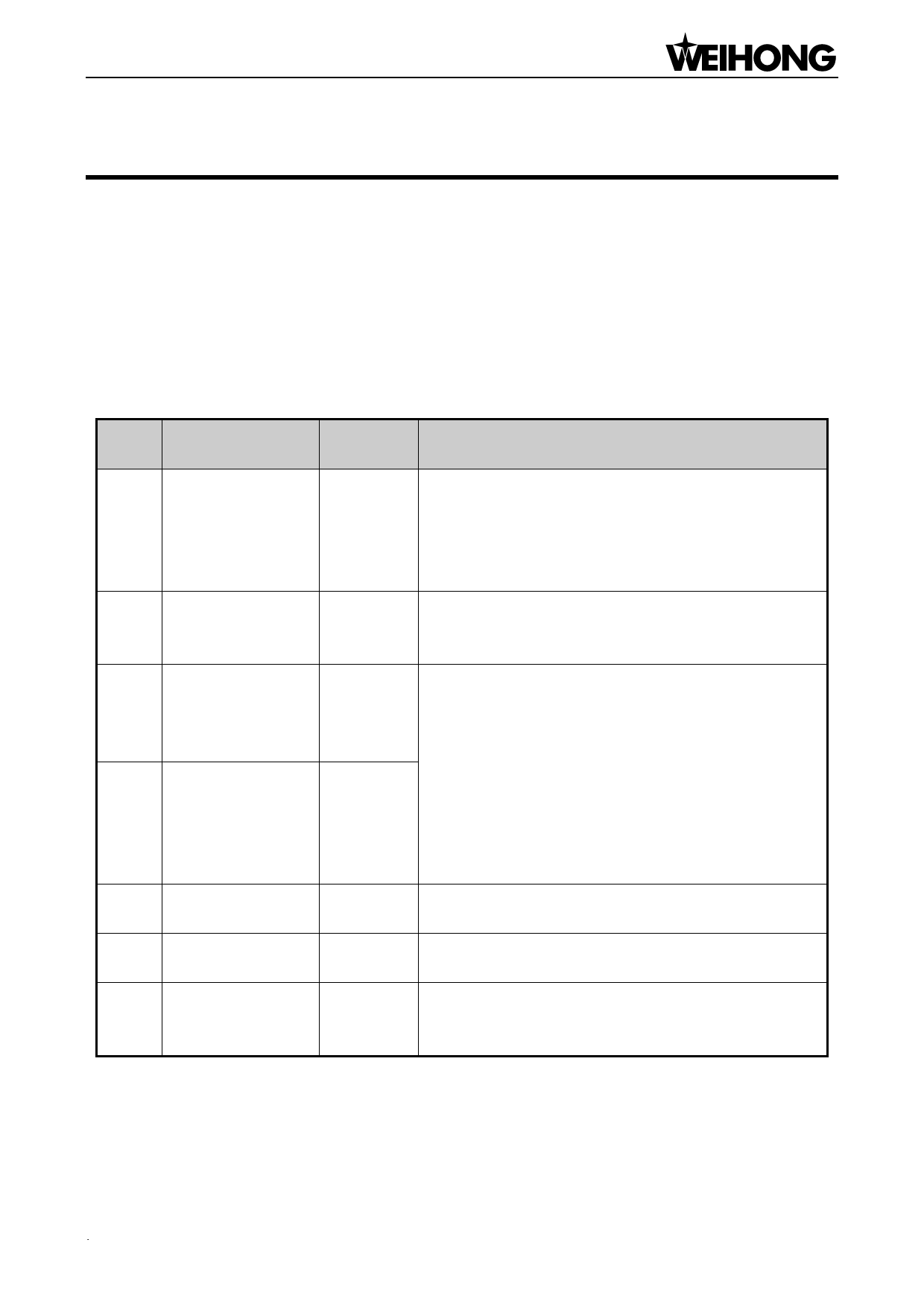

10.1.1. Parameter Setting of WISE Servo Driver

Para.

No.

Pr528

Pr008

Pr009

Pr010

Pr100

Pr101

Pr102

Function

Value

LED initial status 6

Command pulse

No. per motor

circle

1st numerator of

command pulse

frequency division/

multiplication

Denominator of

command pulse

frequency

division/multiplicati

on

1st position loop

gain

1st velocity loop

gain

1st velocity loop

integrated time

constant

0

Need

calculation

Need

calculation

480

(default)

270

(default)

210

(default)

Description

Monitor if the number of sent and received pulses is

correct by setting this parameter. In Weihong control

system, the correct quantity of pulse sent by control

card is detected by pulse inspection in order to

determine whether there is electrical interference.

When it is set to “0”, parameters Pr009 and Pr010 are

valid.

Range: 0~230

Typical value: pitch 5 mm, encoder resolution 10000,

deceleration ratio 1:1, pulse equivalent 0.001 mm:

Pr009=10000

Pr010=pitch 5mm/ pulse equivalent 0.001mm=5000

Pr009/Pr010=10000/5000=2/1

Unit: 0.1/s. Set it according to the actual situation.

Unit: 0.1Hz. Set it according to the actual situation.

Unit: 0.1ms. Set it according to the actual situation.

Driver「83」