- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- EasyRoute-CNC-Router

- EasyRoute CNC Control Panel Manufacture Manual.pdf

- Page 84 of 114

Specialized Concentrated Focused

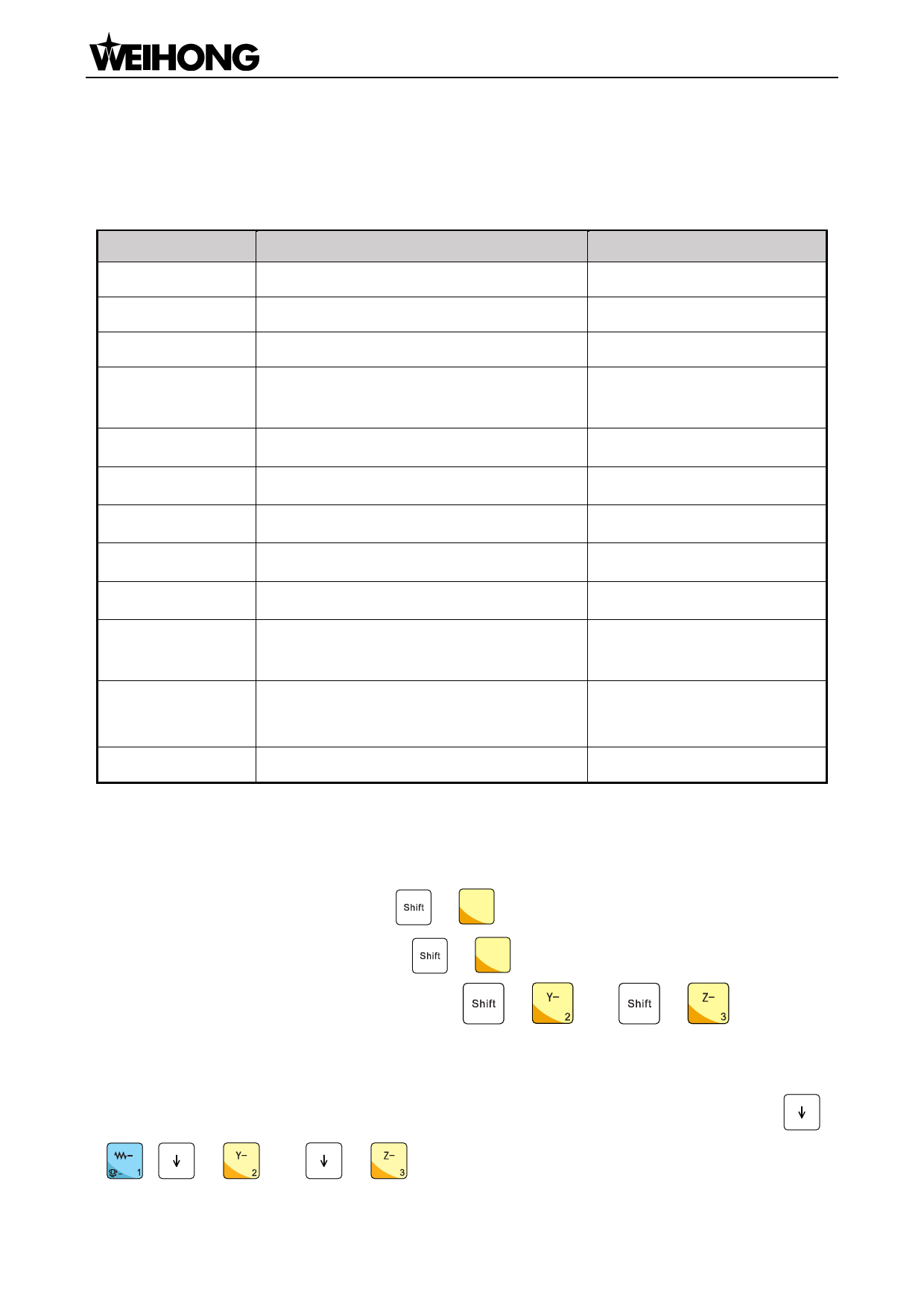

2) Pressing combination key “Shift+Menu key” can open the help page of combination key list.

8.1.2. Tool Change Parameters

You can find “Tool Change” under “Oper Param”.

Parameter

Function

Setting Range

ATC Capacity

Capacity of tool magazine

1~20

CurrentToolNo.

Tool No. of the currently loaded tool

1~ATC Capacity

Tool Offset

Tool offset in each axis direction

X/Y/Z: -10000~10000 (mm)

ToolChangeTip

Cali Coor

Cut Up Pos

Change tool sp

Pre-TC pos

Tool positio

Calibrate Too

Back Pre_Pos

Change Delay

Whether to give a prompt when there is tool Yes: Prompt

change command in the file

No: Not prompt

Machine coordinates

(presetter)

of

tool

sensor /

Machine coordinates of upper position in

tool change

/

Tool moving speed in tool change

0.001~Max. speed of the

machine tool

Machine coordinates of pre-position in tool

change

/

Machine coordinates of currently loaded

tool

/

Whether to automatically measure the tool Yes: Measure

after tool change

No: Not measure

Whether to back to the previous position Yes: Back

before tool change after tool change

completed

No: Not back

Delay time for tool change

0~600000 (ms)

8.1.3. Cylinder Operation Method

3-cylinder 1-inverter software

For NK105G3 CNC system: pressing

“Cut Up Pos”, and start cylinder 1; pressing

IV-

+ 1 in the jog mode will make Z axis lift up to the

IV-

+ 1 again will close cylinder 1. Cylinder 2 and

cylinder 3 can be started and closed by pressing

+

and

+

. Remember

that only one cylinder can be opened at one time. If a cylinder is opened, it will be turned off

automatically if another cylinder is turned on.

To turn on/off cylinder 1/2/3 in NK105G2 CNC system, the corresponding shortcut keys are

+

,

+

and

+

.

「72」Cylinder ATC and Linear ATC Function