- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- EasyRoute-CNC-Router

- EasyRoute CNC Control Panel Manufacture Manual.pdf

- Page 85 of 114

Specialized Concentrated Focused

2-cylidner 2-inverter software

For NK105G3 CNC system, pressing

“Cut Up Pos”, and start cylinder 1; pressing

IV-

+ 1 in the jog mode will make Z axis lift up to the

IV-

+ 1 again will close cylinder 1. Cylinder 2 can

be started and closed by pressing

+

. Remember that only one cylinder can be opened

at one time. If one cylinder is opened, it will be turned off automatically if the other cylinder is turned

on.

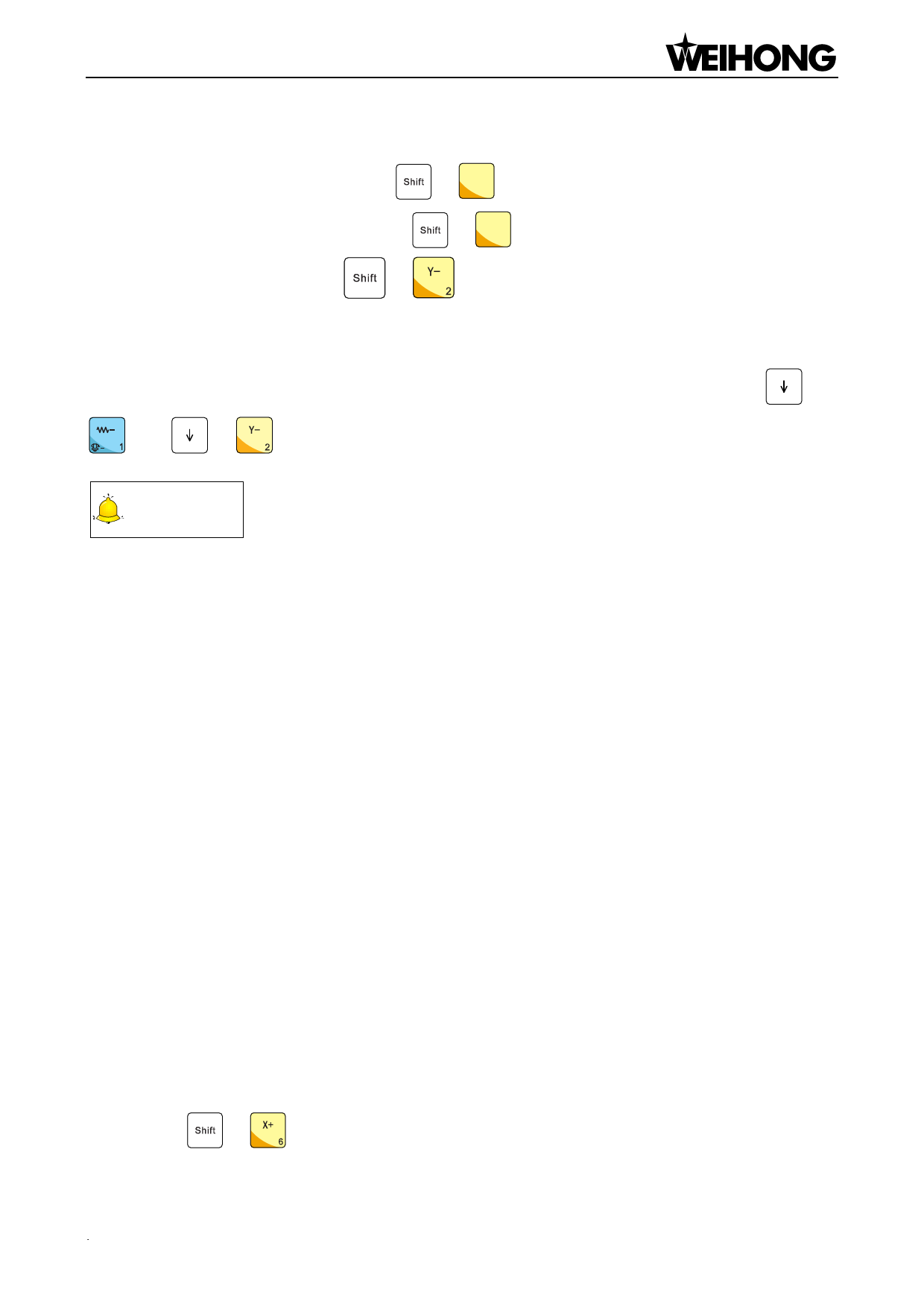

To turn on/off cylinder 1/2 in NK105G2 CNC system, the corresponding shortcut keys are

+

and

+

.

CAUTION

The operations introduced above, taking NK105G2/NK105G3 multi-cylinder software as an example, are

provided for reference only.

8.1.4. Process of Tool Change

3-cylinder 1-inverter software

After machining starts, in case of meeting T1 command, the system will open spindle 1 while

opening cylinder 1; in case of meeting T2 command, the system will close cylinder 1 and spindle 1,

move Z axis to “Cut Up Pos”, open cylinder 2 and spindle 2, and call the position offset of tool 2 for

machining; in case of meeting T3 command, the system will close cylinder 2 and spindle 2, move Z

axis to “Cut Up Pos”, open cylinder 3 and spindle 3, and call the position offset of tool 3 for machining;

after machining finishes, the system will close the current cylinder and spindle.

2-cylidner 2-inverter software

After machining starts, in case of meeting T1 command, the system will open spindle 1 while

opening cylinder 1; in case of meeting T2 command, the system will close cylinder 1 and spindle 1,

move Z axis to “Cut Up Pos”, open cylinder 2 and spindle 2, and call the position offset of tool 2 for

machining; after machining finishes, the system will close the current cylinder and spindle.

8.1.5. Tool Measurement Page

Pessing

+

will open a tool measuring page, where three types of tool measurement

are supported, namely “Manual Set” “Single Measure” and “All Measure”.

Cylinder ATC and Linear ATC Function「73」