- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- EasyRoute-CNC-Router

- EasyRoute CNC Control Panel Manufacture Manual.pdf

- Page 58 of 114

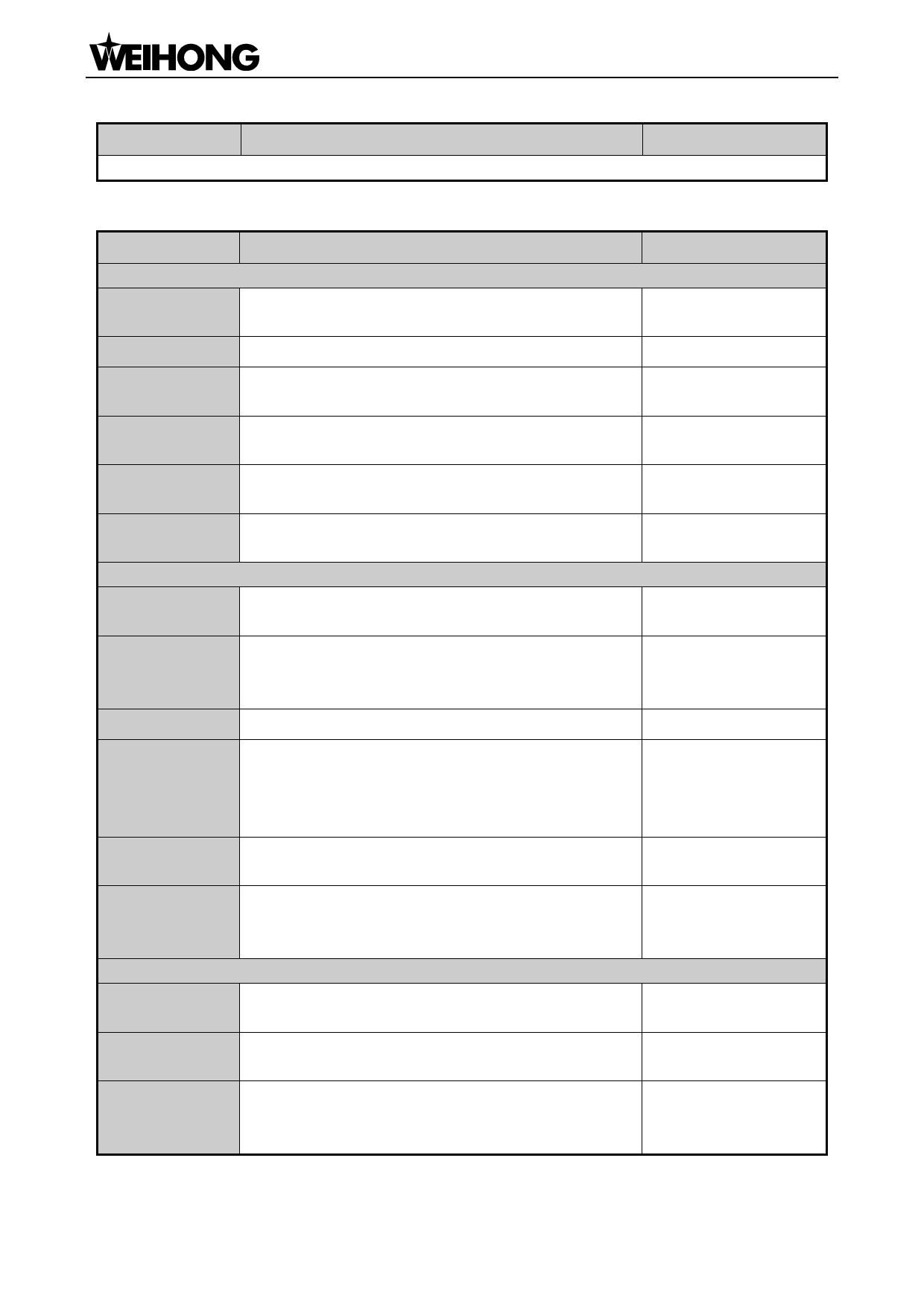

Specialized Concentrated Focused

Parameter

Meaning

Setting range

This group of parameters sets whether to stop spindle under various forms of stop state.

File Parameters

Parameter

Dxf Params

Lifting Height

Process Depth

1st Point as 0

Shape Process

Bottom Process

Metric Size

Eng Params

Lifting Height

ToolChangeTip

Cycle Times

Deep Hole Mode

Retract Amount

Select ToolNo.

Plt Params

Lifting Height

Plt Unit

Tool step

Meaning

Setting range

It sets the tool lifting height of Z axis during rapid

0~99999 mm

traverse when a DXF file is being processed.

It specifies the machining depth for 2D files.

-99999~0 mm

It sets whether to set the first point as workpiece

Yes: Valid; No: Invalid

origin when a DXF file is processed.

The system will not process the next shape until the

Yes: Valid; No: Invalid

current shape is finished.

Valve operation is enabled only when [3D cutting] is

Yes: Valid; No: Invalid

on the workpiece surface.

It forcibly sets a dxf file using metric size.

Yes: Metric size

No: Imperial size

It sets the tool lifting height of Z axis during rapid

0~99999 mm

traverse when an ENG file is being processed.

It sets whether to pause and prompt tool change

when tool change command is encountered during Yes: Valid; No: Invalid

ENG file machining.

It sets the cycle times to process an Eng file.

0~100000

Mode selection for deep hole machining

0: Reciprocating chip

removal; 1: High-speed

reciprocating

chip

removal

Retract amount after each feed in high-speed

0~99999999 mm

reciprocating chip removal mode

If this parameter is set to “Yes”, the machining will be

executed in terms of the specified tool No. in the Yes: Valid; No: Invalid

machining file and only this file will be processed.

It sets the tool lifting height of Z axis during rapid

traverse when a PLT file is being processed.

Normally, 1plt=40.195mm, which can be enlarged or

diminished by setting this parameter.

The value should be confirmed in terms of the tool

diameter and make the adjacent tool paths overlap

for a full machining.

0~99999 mm

0.001~99999

0.0001~99999 mm

「46」Menu Page