- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- EasyRoute-CNC-Router

- EasyRoute CNC Control Panel Manufacture Manual.pdf

- Page 67 of 114

Specialized Concentrated Focused

of pulse is needed, and neither is the reducing amount related to feed direction. In software

compensation, correction of each point on the error curve should be tabulated and saved to the

system memory. Then auto compensation for coordinates of each point is available in running, so as to

improve machine precision.

Backlash Compensation

Hysteresisis caused by forward and reverse clearance. Assume that driving shaft drives driven

shaft in negative (CW) rotation, servo motor will be idling without moving worktable because of

mechanical driving chain backlash, when the driving shaft suddenly begins CCW rotation (positive

motion). After staying at a certain position for some time, the worktable will move backward with the

driving shaft. The same situation will occur when the direction of the driving shaft changes again. We

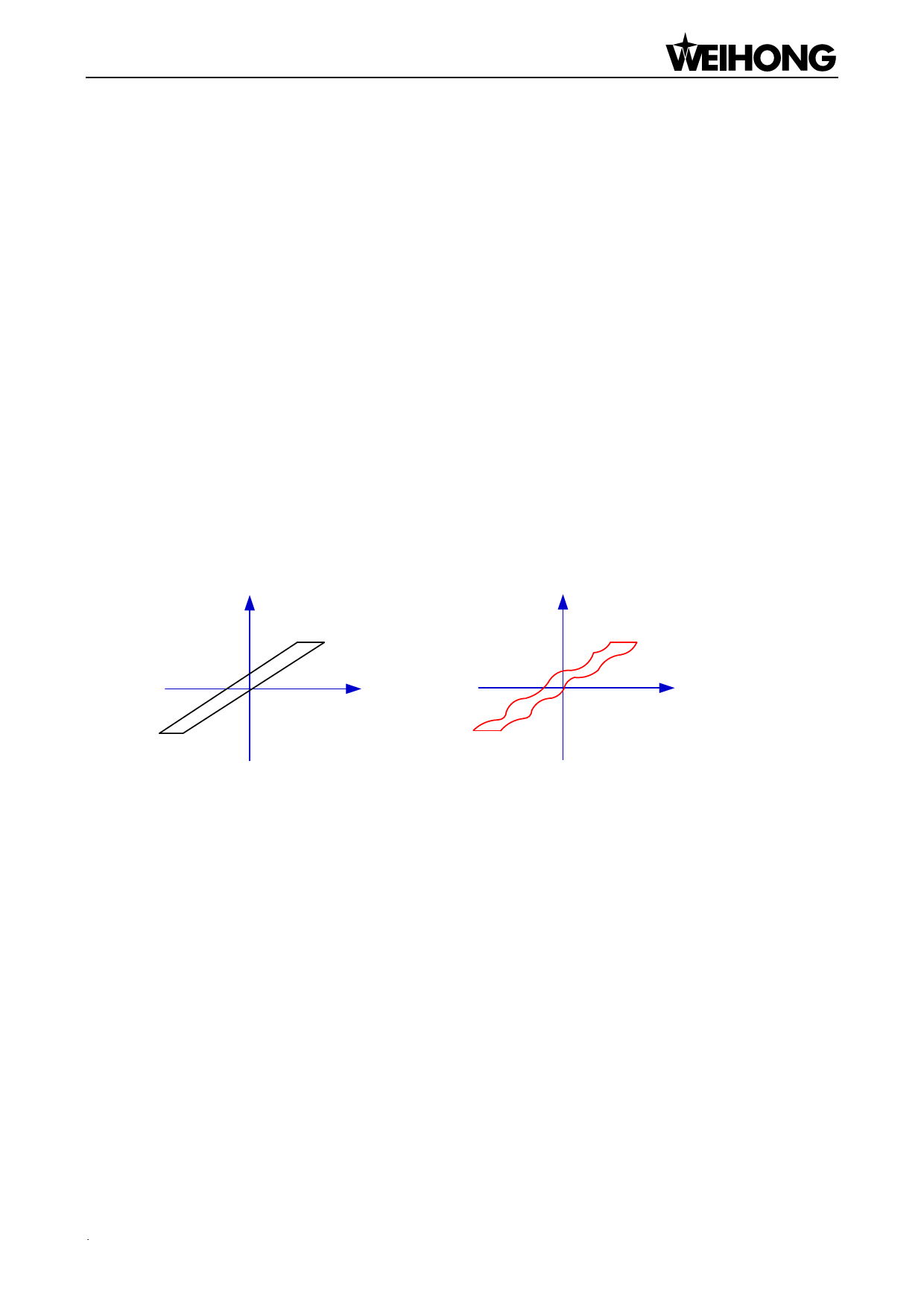

call it Hysteresis. If pitch error doesn’t exist, namely under ideal condition, the moving curve of

worktable is shown in Fig. 6-13 (A), in which the horizontal section is the curve without worktable

movement during the idling of servo motor. The actual moving curve of worktable is shown in Fig. 6-13

(B).

L (Actual value)

L (Actual value)

S (Nominal value)

S (Nominal value)

A Hysteresis feature

B Actual moving curve

Fig. 6-13 Analysis of backlash

To put it in a simply way: because spindle is generally fixed on the screw whose outer wire and the

inner wire on the outer wire cannot be completely matched, the spindle needs to finish the screw

clearance in the last direction when reversing its moving direction. The compensation for the clearance

is called backlash compensation.

Measuring Method and Compensation Method

Backlash can be measured by a specialized gauge. Firstly, fix the gauge besides the spindle and

turn its pointer to the zero position. Secondly, manually move the spindle “a” mm in one direction and

move reversely the same “a” mm. Read the result of gauge, namely the actual moving distance “b” mm,

and calculate the backlash, (a-b) mm.

Input and set the obtained compensation value to the parameter “AxisBacklash”.

Menu Page「55」