65 CypCut Laser Cutting Control System

3. The origin signal is configured correctly and efficiently, so that homing processing is normally

executed.

4. Z signal welding interface of 15 core wire is correct (the 5th port corresponding to Z +, the

13th port corresponding to Z-).

5. Pulse number of encoder feedback is set correctly. You can observe encoder feedback to detect

by manually sending pulse number in diagnostics window.

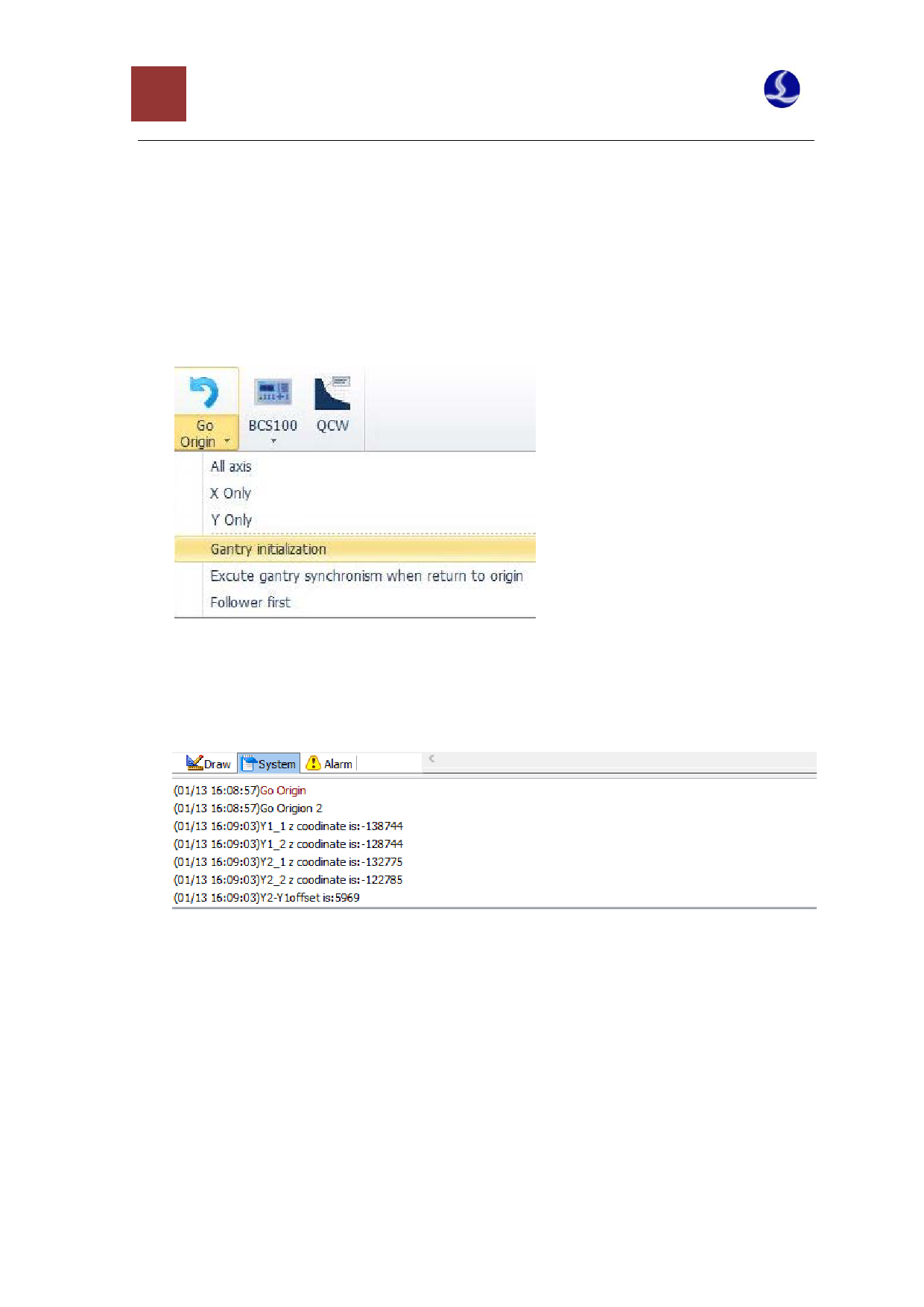

After entering the software, click “Gantry initialization” under "Go origin" drop-down menu on

the "CNC" Page, as shown on the right:

After entering your password, the machine will return to the origin, and then the gantry axis will

move in the positive direction to find two Z signals. After the operation is completed, the system

window under the software displays the position of Z signal and the offset value of the two axes of Z

signal (Y2-Y1 offset):

After completing gantry initialization, select “Excute gantry synchronism when return to origin”

and then enter the password for confirmation.

When select and implement "Go origin" or "Y only”, the software will detect Z signal value of Y1

and Y2-axis and calculate the deviation to compensate. Z signal and the compensation value (Y2

compensate) will be displayed in the system window of the software.