45 CypCut Laser Cutting Control System

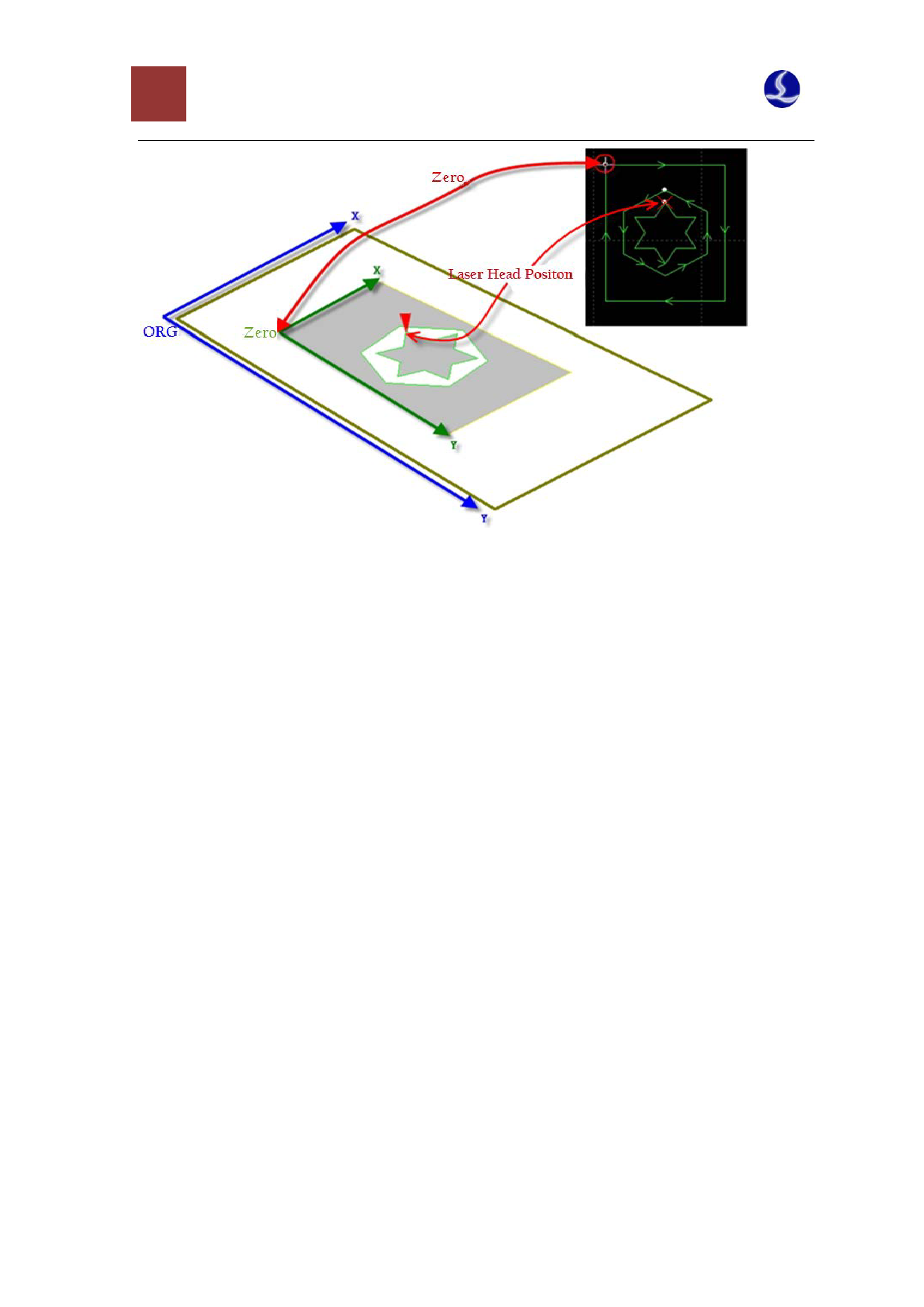

The positional relation between the graphics and the machine tool breadth will be displayed on

the screen after you click the button “preview” on the console.

4.1.1 Mechanical Coordinate System

The mechanical coordinate system is uniquely determined by the machine structure and the

machine parameters. At any time all the coordinate systems set through clicking “Go Origin” are

consistent with each other. You can reset the mechanical coordinate system through clicking “Go

Origin” in the “CNC” page after completing the initial installation or when the mechanical

coordinate system deviates because of the abnormal reasons.

No matter which kind of mechanical structure is used, the definitions of CypCut for the

coordinate systems are always consistent with each other. All the moves are the moves of the laser

head relative to the workpiece. If the laser head is rightward, it is X positive direction; however, if the

laser head is backward, it will be Y positive direction. That is to say, the lower left corner of the

workpiece (steel plate) is the minimum coordinate, while the upper right corner is the maximum

coordinate.

4.1.2 Program Coordinate System

Because the coordinate system of machine tool is fixed, you need to introduce the workpiece

coordinate system for convenient use. The direction of each coordinate axis of all the program

coordinate systems in CypCut is fully consistent with the machine coordinate system. Only the zero

point of the coordinate system is different, and it is called program zero point. The program

coordinate system is divided into the floating coordinate system and the workpiece coordinate

system.