49 CypCut Laser Cutting Control System

stop all the motions.

Note: the soft limit protection depends on the machine coordinate system. If the coordinate

system is not correct, the protection will also be incorrect. Thus, after the operations such as

abnormal close of the system and modification of the machine parameters, users need to build the

correct machine coordinate system through the operation “Go Origin”.

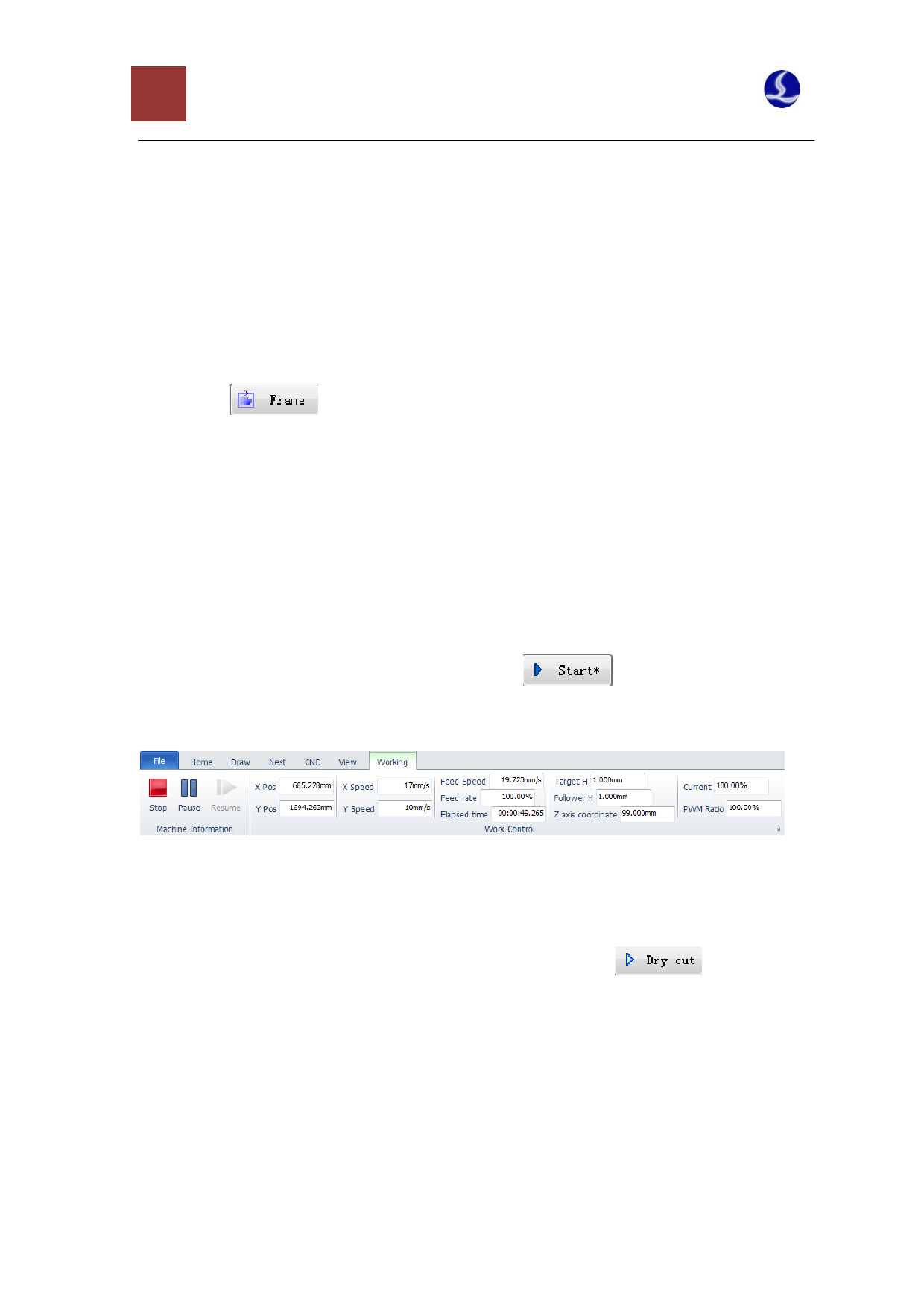

4.5 Frame

The laser head will dry cut a rectangle along the frame of the graphic to be processed by clicking

the button “

” on the console, so that you can determine the approximate size and

position for processing the boards. The speed of walk can be set in the “Layer Parameter Setting” –

“Global Parameters” – “Walk Around Parameters”.

Note: If you operate “Edge Seek” before framing, the software will record the results. The laser

head will move along the inclined rectangle during framing, that is to say, move along the actual frame

which is corrected by the “Edge Seek”. See the Chapter “Edge Seek” for the details.

4.6 Processing and Dry Cut

You can start processing by clicking the button “

” on the console. During the

processing the monitoring screen will be displayed as below. It includes the information such as the

coordinates, the speed, work time, follow height and so on.

When displaying the screen above, it cannot be switched to other pages of the toolbar, in order

to prevent from modifying the graphics during the processing. However, the menu “File” can still be

used. If you need to modify the parameters during the processing, please pause firstly, and then click

the button “Layer” on the right toolbar of the interface.

You can perform the operation of dry cut by clicking the button “

” on the console.

The difference between dry cut and the actual processing lies in that dry cut can select whether to

follow without the need for turning on laser or gas. However, all the running tracks, including the

move, speed, process of acceleration and deceleration of “Prepiercing”, are exactly same to the actual

processing. You can also perform the same operations of pause, continue, forward and backward;

besides, the breakpoint memory after stopping is identical to that of the actual processing;

furthermore, you can modify the parameters after pausing, and then continue the operation of dry cut.

Thus dry cut can be used for the comprehensive inspection and simulation of the whole processing

without cutting.