CypCut Laser Cutting Control System

60

5.9 Deviation measurement

When click "

", the cutting head will move along the graphics to be processed. After the

cutting head finishes move, a blue dotted line will appear to show the trajectory of the servo motor

feedback. You can adjust process parameters required for the actual cutting according to this

trajectory.

VI. Appendix

6.1 Example of Coedge

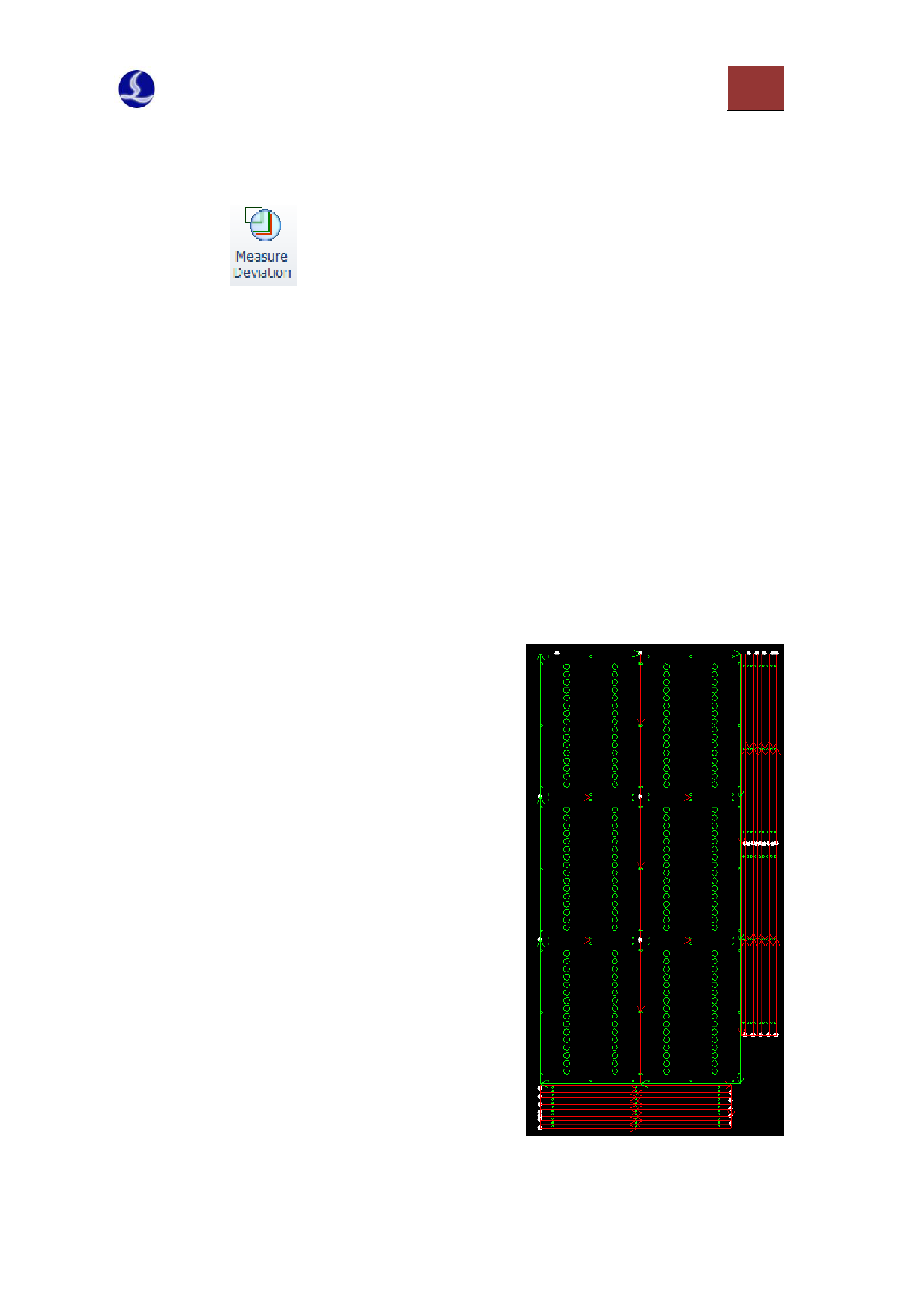

Now we demonstrate edge-shared nesting by taking the actual sample of a customer as an

example. Before setting edge-shared function, the manual drawing of the customer using CAD is as

shown at right.

In the drawing, unclosed graphic is shown in red. All

the graphics in the drawing are straight line requiring

coedge, and the customer drew it manually with CAD

before, so all the graphics have been drawn as straight lines.

It can be seen from the figure that the original drawing

consists of 10 narrow parts below 6 large parts and narrow

workpieces (9x2=18) at right, exactly occupying the space a

steel plate.

We now first draw 3 parts in the original drawing, and

generally the 3 parts are all from the DXF drawings of

customer. As shown below: