CypCut Laser Cutting Control System

10

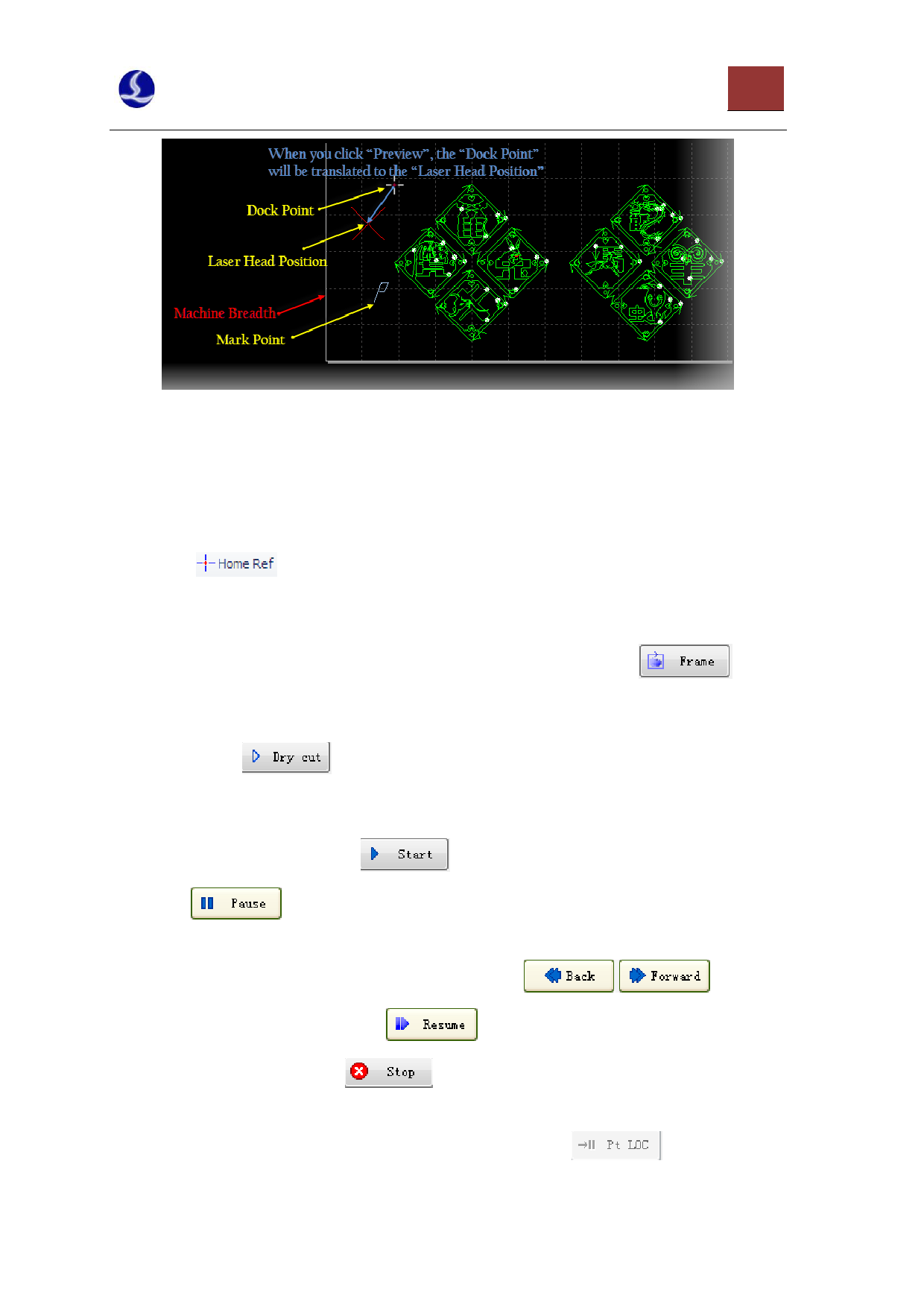

If the “Laser Head Position” shown by the red cross cursor does not match the actual laser head

position of the machine, please check whether the position of the machine origin is correct, and it can

be corrected through “Numerical Control”—“Go Origin”. After previewing, if you find that the

graphics are outside the machine breadth wholly or partially, it means that it may exceed the range of

travel during processing.

You can change the relative relationship between the graphics and the dock points by clicking

the button “

” under “Home” menu. For example, if the laser head is at the lower left

corner of the upcoming processing work-piece, you can set the lower left corner as the dock point and

so forth.

If there is no error on the screen after checking, you can click the button “

” on the

“Console”, and the software will control the machine to go around the outer frame of the upcoming

processing graphics so that you can check whether the working positions are correct. You can also

click the button “

”, and the machine will run completely without laser along the

graphics which will be processed so that you can check more carefully whether there may be any

impropriety in the processing.

Finally please click the button “

” to start the formal processing, and you can click

the button“

” to suspend the processing. During the suspension, you can control the

laser head to go up and down manually, and switch the laser, gas and so on manually, besides, you can

also trace back along the working route through the buttons “

”. You can

continue to work by clicking the button “

”.

You can click the button “

” to stop the processing and the laser head can

automatically return to the corresponding point according to your setting. As long as you do not

change graphics or start new processing, when click the button “

”, the system will