CypCut Laser Cutting Control System

46

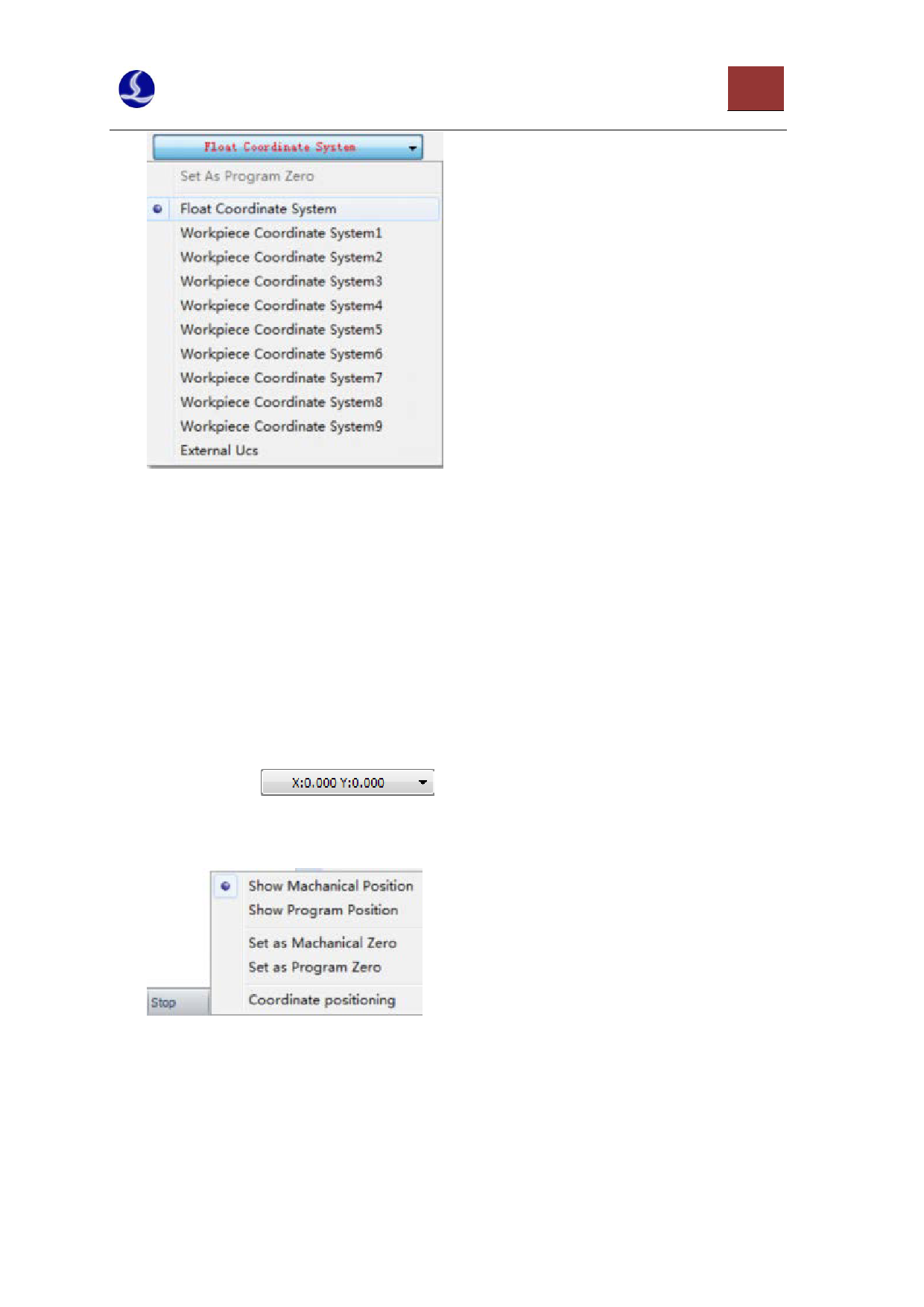

The button at the top of the console can be used to select the program coordinate system, and it

can also be used to select “Floating Coordinate System”, nine “Workpiece Coordinate Systems” and

one “External Ucs”.

Usually the floating coordinate system is used for informal processing, and it can be considered

that “Where the laser head moves, it will start to work from there”. The zero point of its coordinate

system is automatically set as the current position of the laser head when the users click “Walk”, “Dry

Cut” or “Work”.

When selecting the workpiece coordinates 1~9, its zero point will be set manually by the users

through “Set the Current Point as the Zero Point”. Once it is set, it will be saved forever until you

reset it next time. Thus the workpiece coordinate system is suitable for bulk production, and its

location is generally decided by the fixture. It can be maintained that every processing will be

performed in the same position of the machine by using the workpiece coordinate systems 1~9.

Click status bar "

"at the bottom. You can choose to “Show Machanical

or Program Position. You can also set zero here of the two coordinates. If you select "coordinate

positioning", laser head will be positioned to a specified coordinate position.

4.1.3 Searching Zero Point after Exception Occurs

Case one

If the processing is interrupted only due to the exception of external equipments such as the