5.11 Height Sensor

XC3000Series Motion Control System of Laser Cutting - User Manual

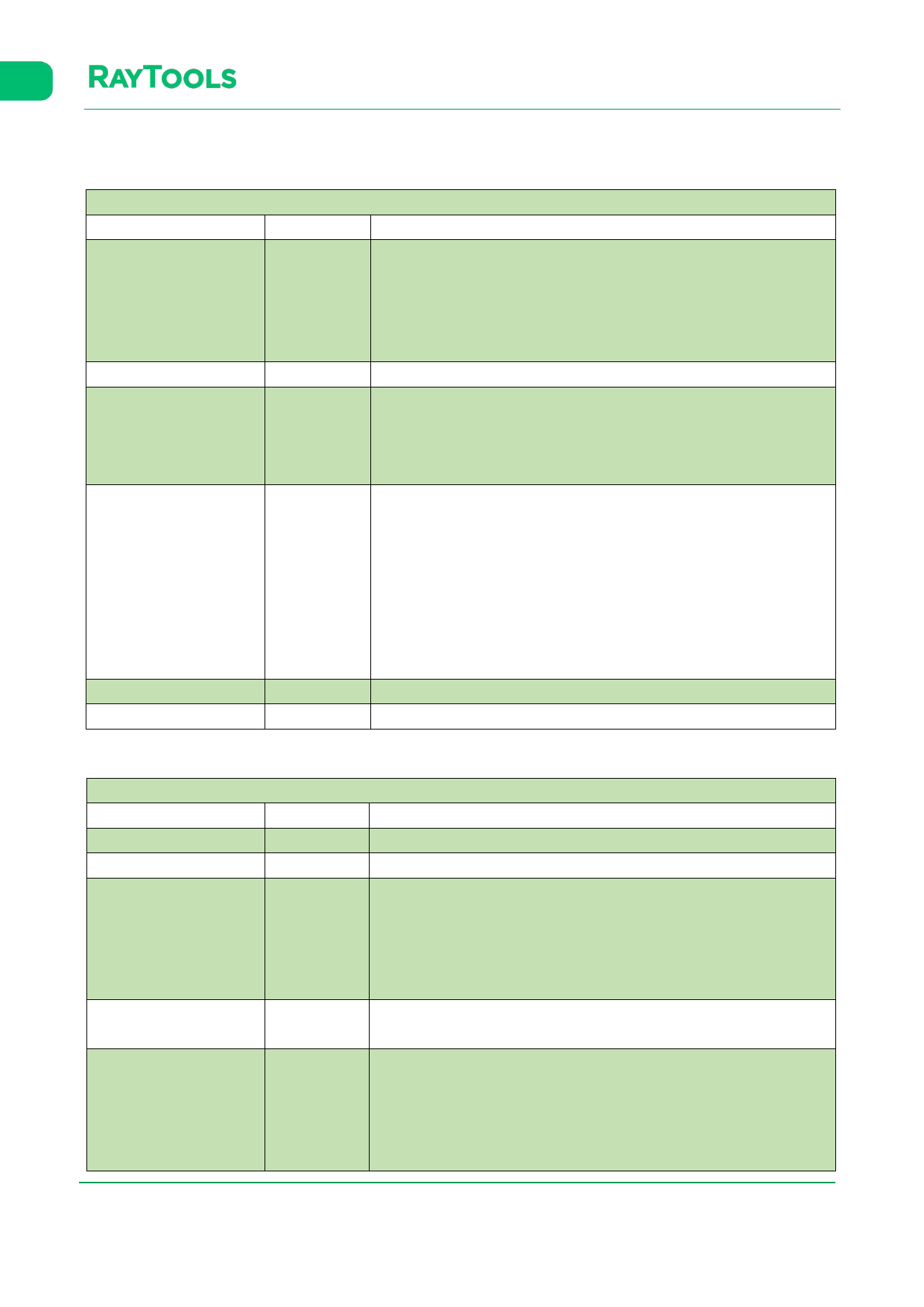

Click on Height Sensor in CNC sub-page, and the setting interface which contains the following parameters will pop up:

Lifting

Parameter

Default

Remark

After Z-Axis follow-up completes, the max lifting height is the lifting

Max lifting height

30

(among contours)

height of the cutting head bases on its current position. It is

recommended not to set the value too large. The value can be set as

half of the Z-axis travel. A value that is too larger may reduce the

cutting efficiency.

Optimize short travel

Enable

Enable: use the function. Disable: not use the function.

Using the function of optimizing short travel, if the linear distance

Short travel

between the end of the current contour and the start of the next

8

contour is less than the value, the cutting head will move to the start

of the next contour in the follow-up state.

Enable: the cutting head will move and lift simultaneously while it

completes cutting one contour and travels to the next one. When the

cutting head gets close to the position, it will follow down in advance

Open LeapFrog

Enable

to improve efficiency. Disable: while the cutting head completes

cutting one contour and travels to the next one, it will lift at first and

then move to the start position of the next contour, and last it will

follow down to reduce the risk of touching the plate.

Leapfrog takeoff height 0

Max frog drop distance 20

It refers to the takeoff height of the Leapfrog function.

It refers to the max distance when the cutting head frog-like drops.

Parameter

Follow level

Follow speed

Default

7

18

Follow max height

5

Real-time calibration

Select.

Calibration jump value 1000

V1.0

Follow-up Parameter

Remark

The default is fine, and generally, it does not need modification.

It refers to the maximum speed when follow down.

If the follow height is larger than the value, the cutting head will follow

up to 1mm from the plate and then lift to the follow height.

Meanwhile, the follow-up is in closed state for the accuracy of height.

If the follow height is smaller than the value, the cutting head will

straightly follow-up to the follow height to improve the efficiency.

Optimize the algorithm at the set time to make the calibration data of

capacitance more accurate.

Select capacitance jump to be the touch-plate signal when calibrate,

and the value will take effect.

Parameter definition: during calibration, when the cutting head is

seeking the plate, if the absolute value of the difference between the

capacitance value of the current cycle and the capacitance value of the

Raytools AG © Copyright

www.raytools.ch

80 |87