Page 71 of 94

XC3000Series Motion Control System of Laser Cutting - User Manual

The coordinate system is the right-handed Cartesian coordinate system. As shown in the figure, the thumb is pointing in

the positive direction of the X axis, the forefinger is pointing in the positive direction of the Y axis, and the middle finger is

pointing in the positive direction of the Z axis. With the X, Y, and Z coordinates determined, it is easy to determine the

direction of the A, B, and C rotational coordinates according to the right-hand spiral rule.

4.1.1 Machine Coordinate System

The machine coordinate system is only determined by the machine structure and its parameters. It can be established by

clicking on Return Origin button, or by clicking on Return Origin button in the CNC sub-page to re-establish the machine

coordinate system while initial installation or when there is any derivation for abnormal reasons.

4.1.2 Program Coordinate System

As the position of the workpiece may vary, it is necessary to introduce a workpiece coordinate system for ease of use. All

the program coordinate systems in the software are identical in direction to the machine coordinate system. Only the

zero point of the coordinate system is different, known as the program zero. The program coordinate system contains a

floating coordinate and workpiece coordinates.

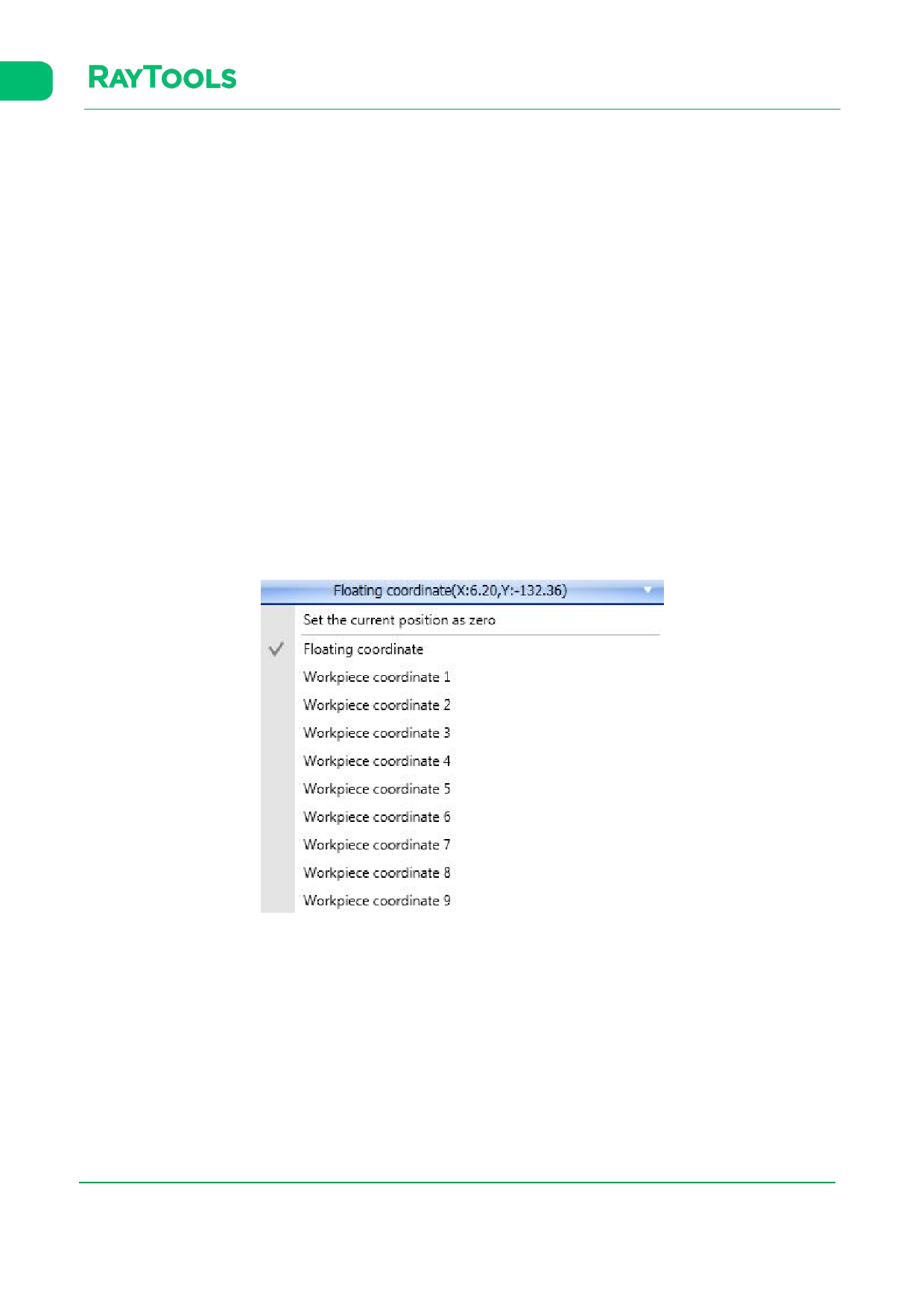

The button at the top of the control panel is used to select the floating coordinate system and other nine workpiece

coordinate systems.

V1.0

Raytools AG © Copyright

64 |87

www.raytools.ch