XC3000Series Motion Control System of Laser Cutting - User Manual

(1) Fly Cut Mode:

Circle: select to cut in circular path.

Linear: select to cut in rectangular and polygon-shaped path.

Radar: linear cutting path without smooth arcs. Other cutting modes include Obround and Leadline.

(2) Sort Mode: select different sort modes to use different fly cutting paths.

(3) Starting position: select the start position of the graphic to be processed.

(4) Tolerance: if the horizontal and vertical length of the graphic is smaller than the tolerance, the graphic will be in a line

or an array; if larger, the graphic will be in multiple lines or arrays.

(5) Max Smooth Joint: if the distance between two graphics is less than the max smooth joint length, an arc tangent will

be auto-added to the cutting path to speed up processing and improve efficiency.

(6) Smooth Arc Radius: radius of the arc mentioned in Max Smooth Joint.

(7) Z-axis not Lift Between Fly Groups: select to lift the Z-axis in the travel between two groups in fly cutting.

(8) Laser leads length: laser on in advance for better cutting off the workpiece.

(9) laser lags length: as over-cutting distance, laser off delay is for better cutting off the workpiece.

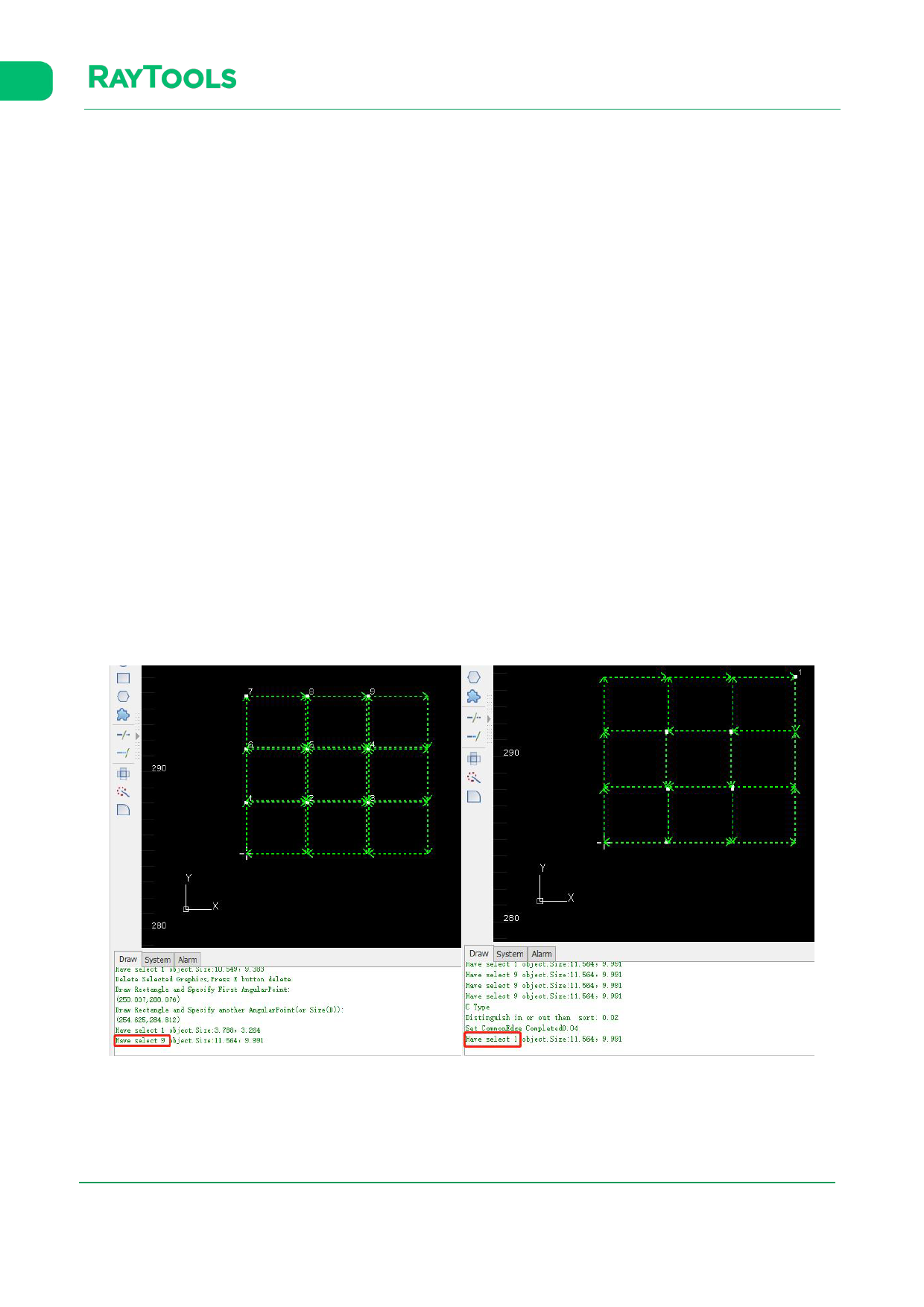

2.1.24 Co-edge

Combine workpieces with common edges to use one edge for cost efficiency and improve processing efficiency.

Select graphics to be co-edged and click on Co-edge button in the Home sub-page. Co-edge parameter setting pops up by

which you can select T-type or common co-edge, and the way to sort. Click on OK to complete. After co-edging, the

graphics will be grouped into one contour to avoid sorting errors. The result of co-edge is shown below:

V1.0

Raytools AG © Copyright

37 |87

www.raytools.ch