Friendess CypCut Laser Cutting Control System

65 / 103

CypCut defines coordinates with same rules no matter what mechanism applied.

Stand front of the laser head, laser head towards right is X+ direction, towards back is

Y+ direction which means the left bottom is the minimum coordinate.

4.1.2 Program Coordinate System

Mechanical coordinate is

consistent, CypCut also adopts

workpiece coordinate. Workpiece

coordinate X/Y direction same with

the mechanical coordinate system, only 0 point different and called program 0 point.

Program coordinate system is divided into floating coordinate system and workpiece

coordinate system.

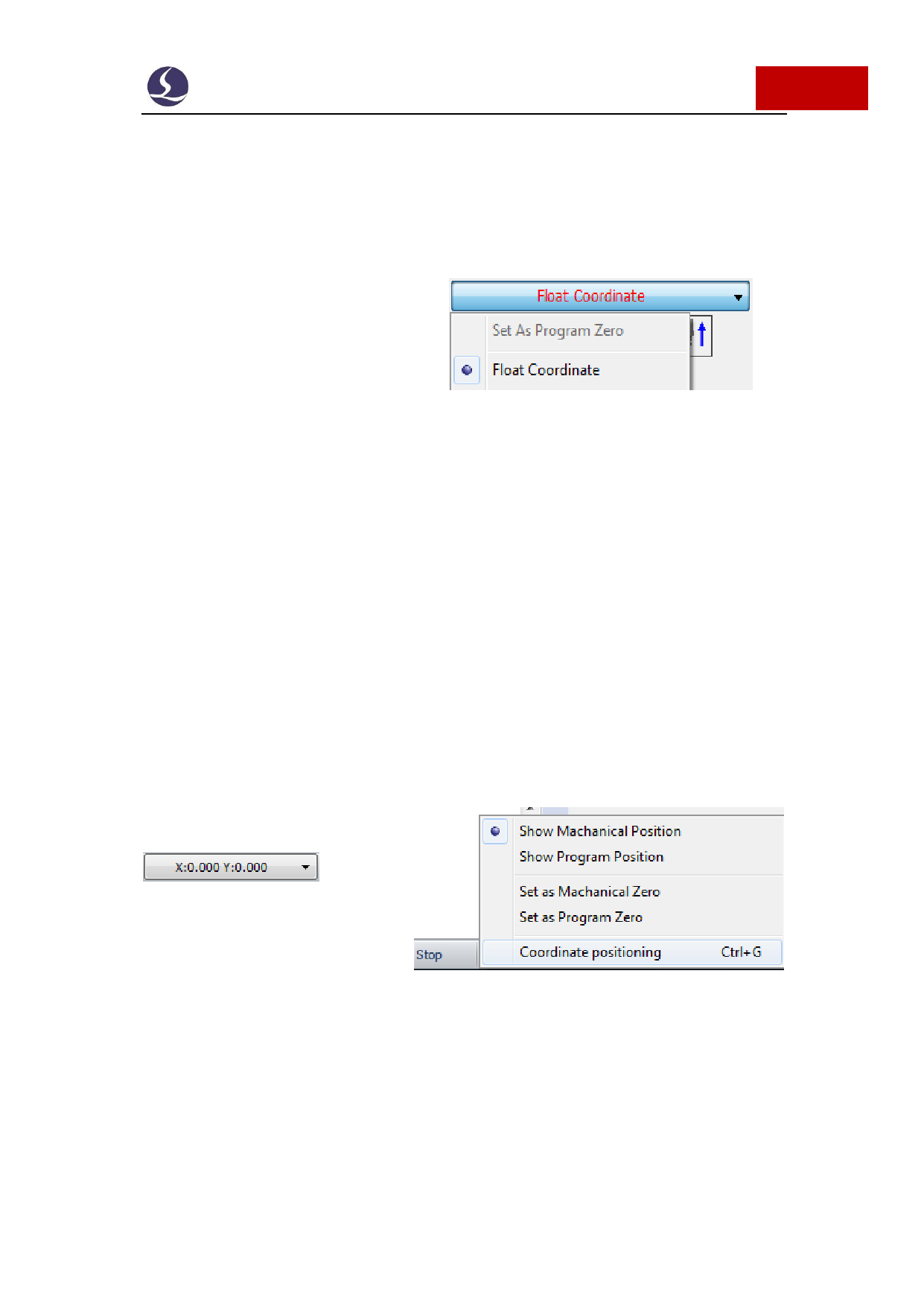

Click the button above the console panel you can select 'Floating coordinate’,

'Workpiece coordinate' or 'external coordinate'.

Floating coordinates used in cutting samples or small quantity parts. Laser

head will start machining from current position.

If select workpiece coordinate, the zero point is manually set by users.

Workpiece coordinate applied for large quantity production. This will assure

machining starts from same position on the machine every time.

Click the status button

at bottom

screen.

You can select to display

mechanical coordinate or program coordinate and specify the zero point of the

coordinate. Select 'coordinate positioning' will locate the cutting head to the specified

coordinate position.

4.1.3 Find Zero Point after Interruption

Situation 1