7 FSCUT2000C laser cutting control system User Manual

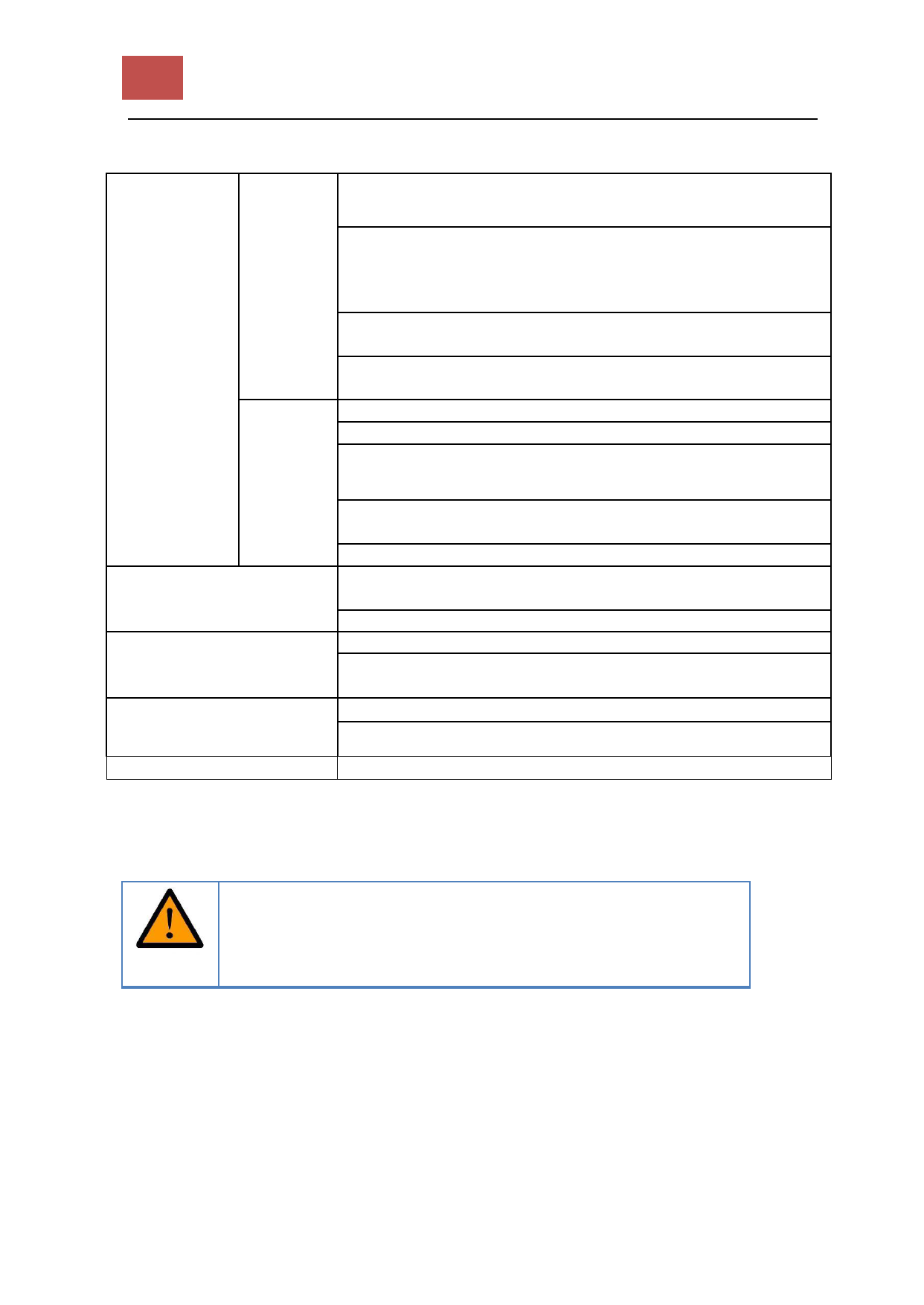

1.3 Technical parameters

4 axis with high-speed pulse output and maximum

frequency3MHz

Motion

control

Motor

control

signal

Motion

control

performance

Laser control signal

I/O Function

Work environment

Power requirement

3 axis with encoder feedback channel and four times

frequency up to 8MHz

The original point of every axis with limit, servo

alarm special input signal.

The servo performance of every axis, alarm clear

special output signal.

Control cycle is 1ms.

“S” speed-up and speed-down with wave filtering.

Velocity look-ahead, inflection point with intelligent

speed-up and speed-down.

The speed limit of small circular arc, Local curvature

analysis

The smoothing of turning

Output 1 is PWM signal, with dip switch choosing

24V or 5V.

Output 2 is 0~10V analog signal.

12 general inputs.

20 general outputs, thereto, 8 interfaces are relay

outputs,12 interfaces are mosfet emitter outputs.

Temperature: 0~55℃

humidity: 5%~90%, no condensation

24V,2A

1.4 Control card installation

1.4.1 Installation steps

Please be careful, and effectively touch grounded metal parts before

touching control card system or inserting/removing control card, in

order to prevent static electricity from damaging motion control

card, and please wear electricity-proof gloves.

(1) Shut down computer, insert control card into PCI slot, and fix control card

and catch screw of expansion winding displacement.

(2) After start the computer, the window of “Driver Software Installation” pops

up; click “Close” button as shown below. If this window does not pop up, it means

control card is not inserted correctly. So please repeat step one.