15 FSCUT2000C laser cutting control system User Manual

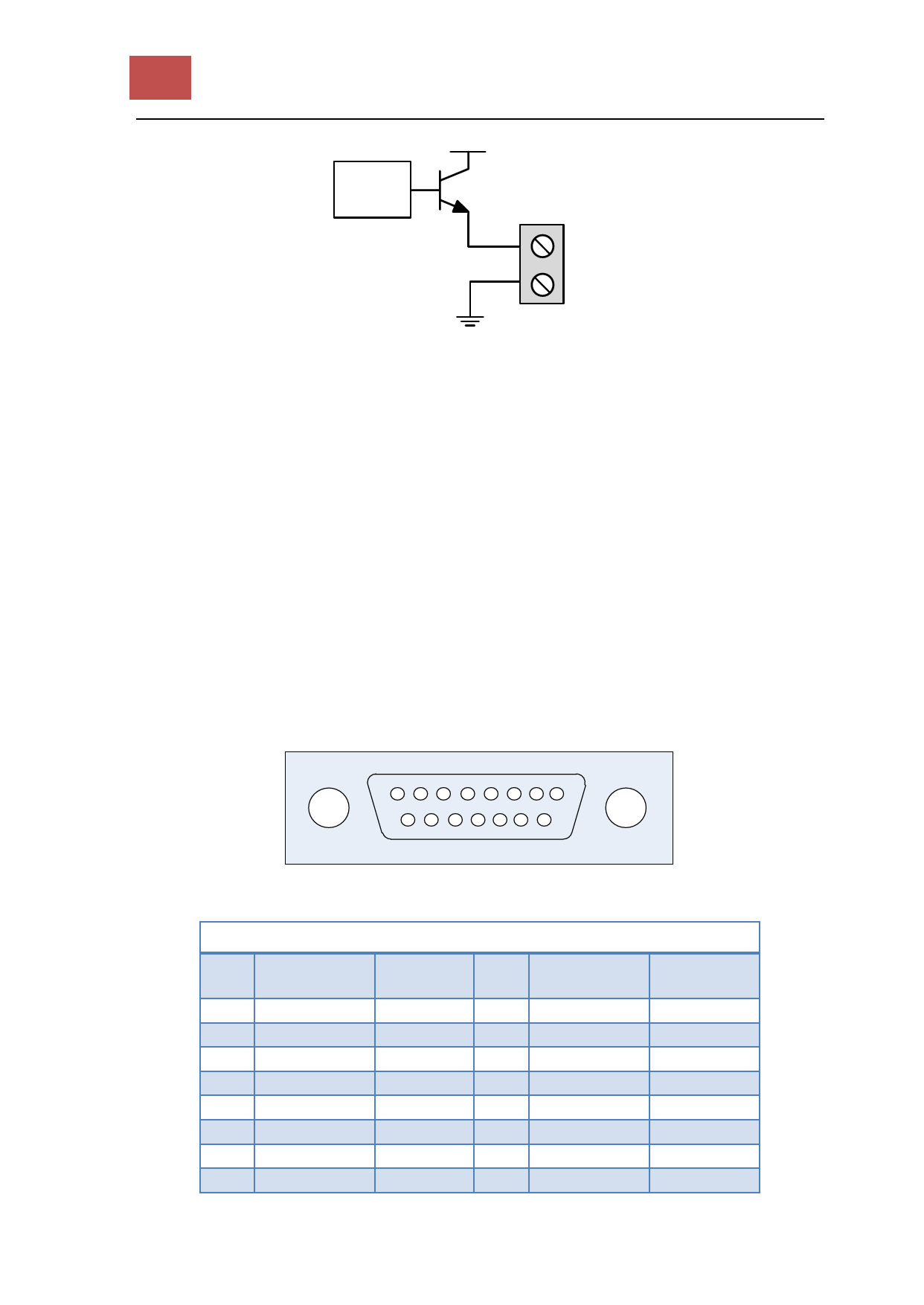

VCC

PWM

signal

PWM+

PWM-

We strongly recommend that users install PWM+/- signal to a relay output port

in series (Set it to PWM+/- enable signal.), then access to the laser, which can avoid

laser light leakage in modulation mode. Please refer to “2.5 Laser Connection” for

more details. Furthermore, please adjust PWM signal level. 24 V or 5 V level can be

selected through dip switch.

2.3 Terminal Instructions

2.3.1 External power source

External power source provide direct current 24 V for BCL3766 External IO Board. 24

V and COM of power input terminal are connected to 24 V and 0V of power output

interface, respectively.

2.3.2 Servo control interface

The four servo control interfaces on BCL3766 are DB15 two-row bores, and pin

definition is as below:

8 7 6 5 4 3 2 1

15 14 13 12 11 10 9

The signal definition of matched servo cables is shown as below:

15-pin servo control signal Line

Pin Line color

1

Yellow

2

Blue

3

Black

4

Orange

5

Red

6

Green

7 Green-Black

8

Brown

Signal Pin Line color

Name

PUL+

9 Yellow-Black

DIR+

10 Blue-Black

A+

11 White-Black

B+

12 Orange-Black

Z+

13 Red-Black

SON

14

Purple

CLR

15 Brown-Black

24V

Signal

Name

PUL-

DIR-

A-

B-

Z-

ALM

0V