67 FSCUT2000C laser cutting control system User Manual

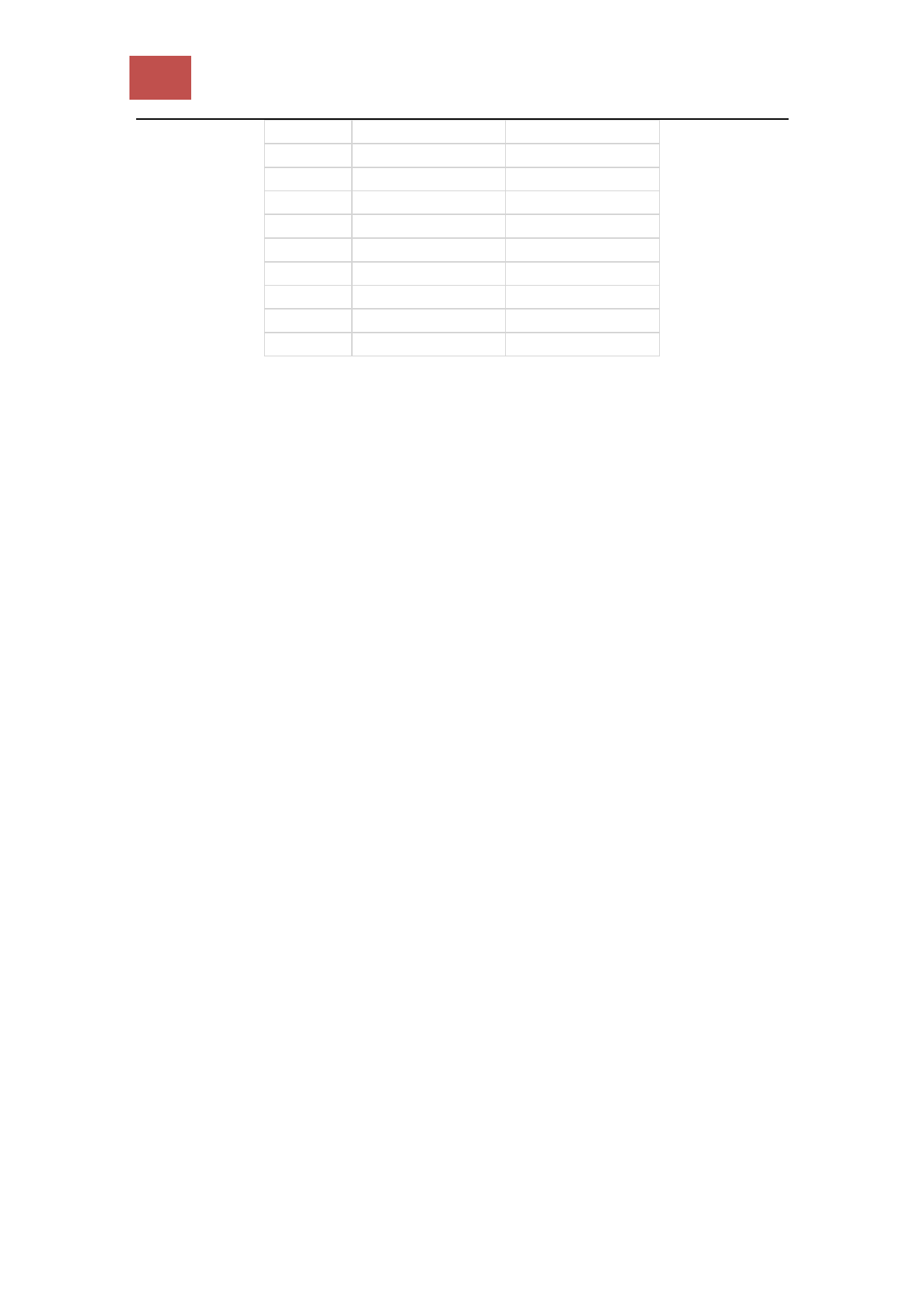

Position

0

50

100

150

200

250

300

350

Positive

0.001

50.0021

100.0032

150.0043

200.0054

250.0065

300.0076

350.0087

negative

-0.0005

-49.9932

-99.9859

-149.9786

-199.9713

-249.964

-299.9567

-349.9494

2. Open platform configuration of software – pitch compensation - Import above

documents

6.7.7 Operation sequence

1. Mechanism return to origin;

2. Set interferometer to get parameter;

3. Set parameter on optical adjustment interface of cypcut, generate

interferometer locating procedure.

4. Use interferometer to measure error, get mechanism date;

5. Import interferometer data in the tool of platform configuration and save it;

6. Mechanism return to origin;

7. Use interferometer to measure error again, verify the result of pitch

compensation;

6.7.8 General problem solving

1.The compensation without changing before and after

Return to origin after compensation, than compensation data will be valid.

If set the pulse equivalent as 200Pulse / mm or less, compensation data will not

be valid.

2. Error doubled after compensation

If it is found that the shape of the forward and reverse error curve is almost no

change after compensation, but the value almost doubled and the distance between the

two curves is also doubled (That is, reverse interval), it is likely that the sign of error

value is reversed. In this case, click the "error value inversion", which can make

compensation accuracy is greatly improved.