FSCUT2000C laser cutting control system User Manual

64

to the motor. For example, transmit the number of pulses which can make servo motor

run a circle, and then measure the distance between the two points by the

interferometer. It’s ok to fill the ted number of pulses and the distance in the platform

configuration tool.

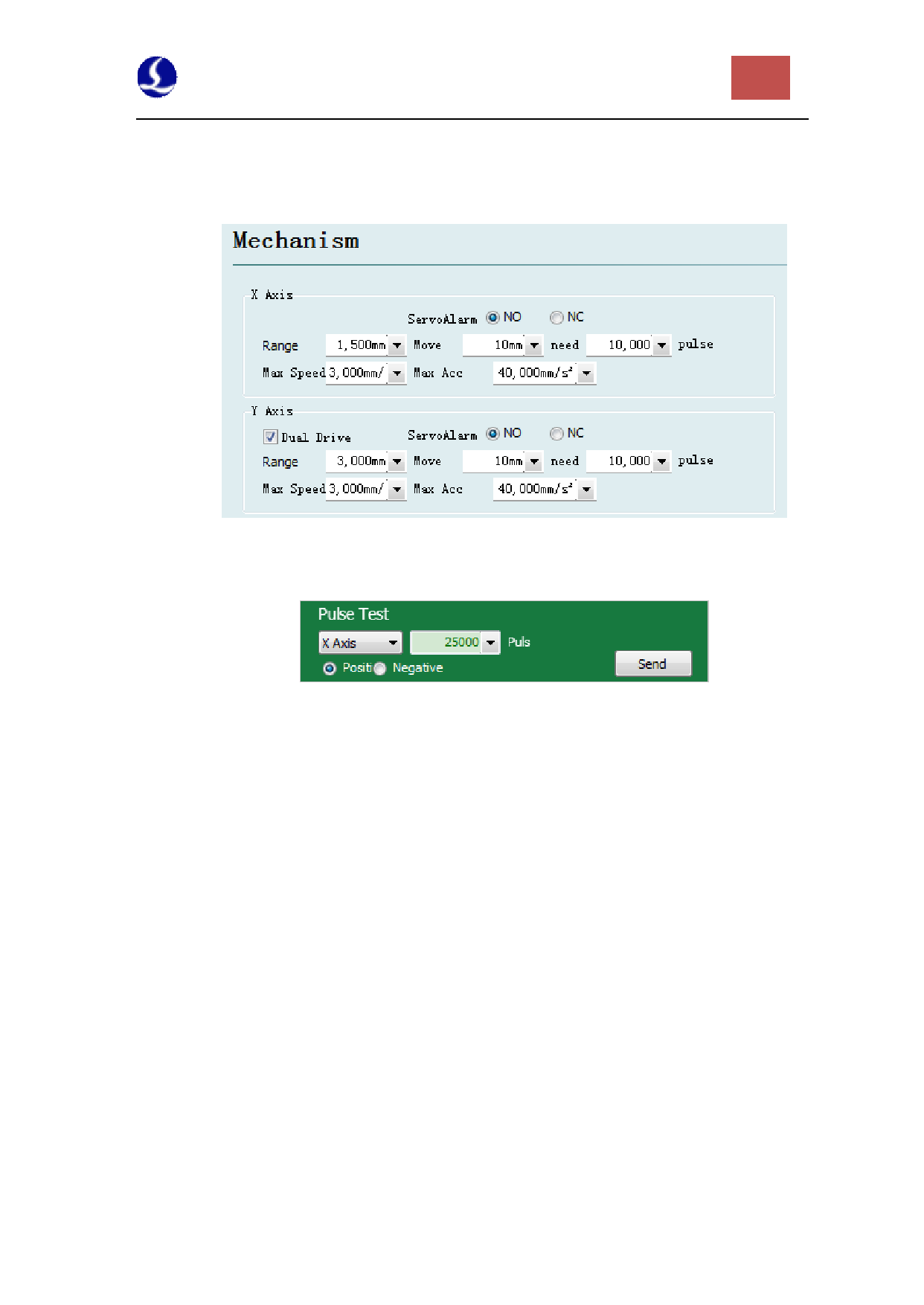

The method of sending a fixed number of pulses in CypCut is to open the "File" -

"Diagnosis", select shaft as shown in the following figure window, input the pulse

number, and click "Send."

6.7.4 Error measurement

The error is measured by the interferometer, commonly known as "Open

interferometer." Generally, control the machine to stay for some time at an interval

distance by the numerical control system, and then laser interferometer can measure

the actual position of each point. The correspondence table of the theoretical position

and the actual position can be obtained after all location measurement has been

completed.

Most of the laser interferometers, such as Renishaw, must first set travel range,

test interval and time spent at each point before starting the test, for example, stay one

second every interval 30 mm. Laser interferometer decides whether to be measured by

determining the separation distance and dwell time.

Firstly, determine several parameters:

Travel range. The total travel range of preliminary measurement, generally is set

slightly smaller than the stroke of the machine design.

Measurement interval. Theoretically, the smaller the measurement interval is, the

more accurate the results is after the compensation; but the smaller the measurement

interval is, the more the point required to be measured is, and also the longer time it

takes. Recommended interval value is between 10 mm to 100 mm.

Dwell time. The minimum dwell time of Renishaw default is two seconds.

Opens CypCut- "Numerical Control" - "light path adjustment" screen, and find

the following window: