FSCUT2000C laser cutting control system User Manual

28

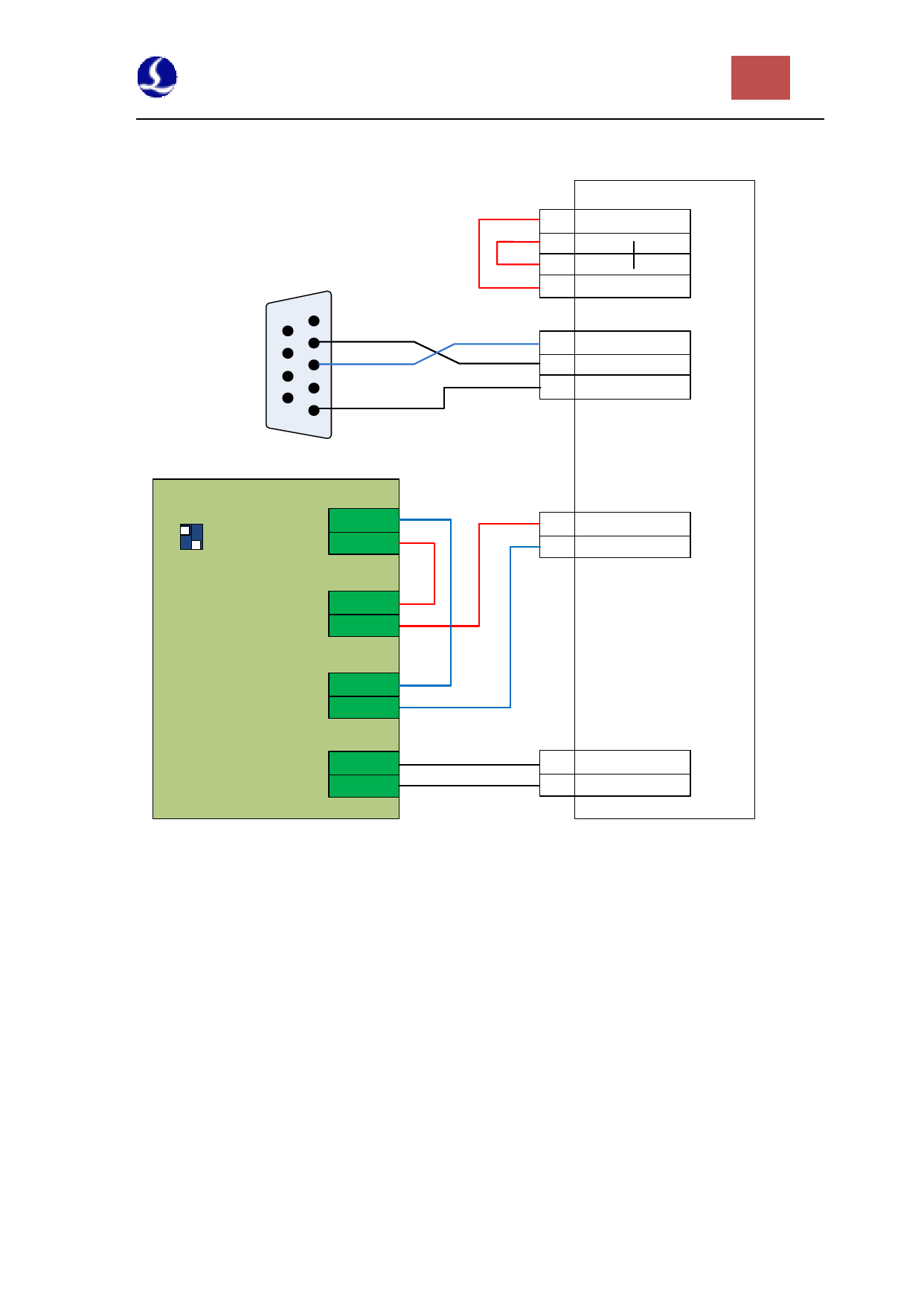

2.5.3 IPG-YLR series wiring diagram

IPG_YLR-24Pin

RS232 DB9

1

62

73

84

95

1 Interlock Ch1A

2 Interlock Ch2A

3 Interlock Ch2B

4 Interlock Ch1B

5 RS232 Rx

6 RS232 Tx

7 RS232 COM

BCL3766

Dip switch

ON

1 2

PWM

output

PWM-

PWM+

relay output

NO

CON

15 Modulation+

16 Modulation-

NO

relay output

CON

NO

relay output

CON

10 Remote Start

11 Remote Start

When the laser you are using supports serial or Ethernet communications control, we

strongly recommend that you connect communication ports (serial or network interface).

Using serial or Ethernet communication, CypCut software will monitor laser status in

real-time, and can operate lasers by means of communication. Implementation including

switch shutter (Emission), switch red (Guide beam), set the peak power (Current) and other

actions, no longer need to connect the analog interface to control the laser peak power.

Recommended network interface of IPG-YLR series.

Notes

1. remote start button cannot be connected, especially when the laser is not in a

good grounding , we do not recommend users to add remote start button, which is

easy to cause the laser to produce failure.

2. PWM select 24V control (Dip switch: 1 pin is ON, 2 pin is OFF;Optionally

select one among 3 pin and 4 pin is ON, then another one is OFF