55 FSCUT2000C laser cutting control system User Manual

5.2.4 DELTA servo debugging experience

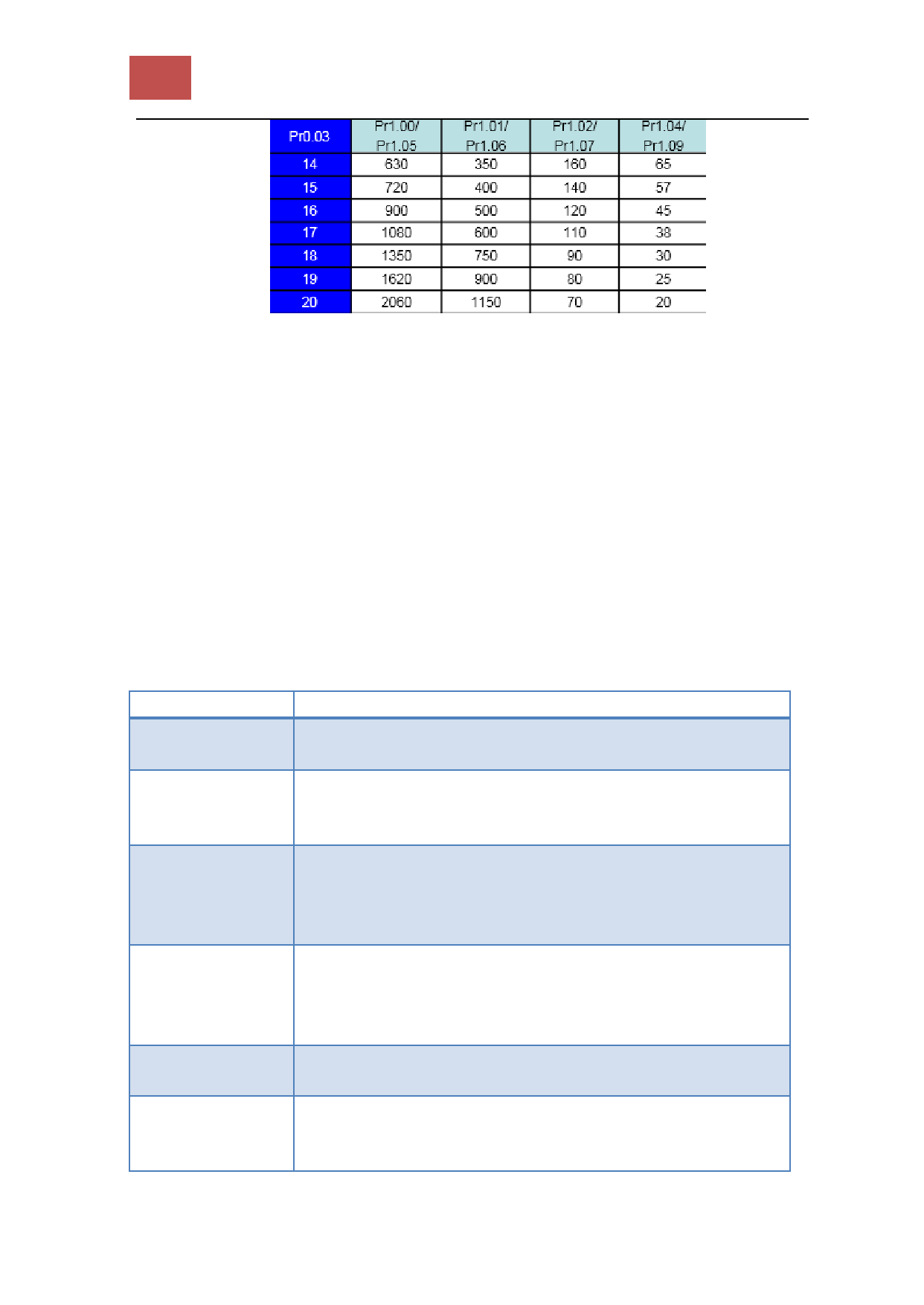

Delta servo debugging can also refer to the rigidity table of Panasonic. The

reference method is shown as below:

The parameter P2-00 KPP is the equal of the position loop gain of Panasonic.

Though its unit is rad/s, actually, It's 1/s. For example, when the P2-00 KPP= 90, it’s

the same as Pr100=900 of the position loop gain of Panasonic.

5.3 Motion Control parameter adjustment

5.3.1 Motion control parameter introduction

FSCUT2000C system mainly opens these four types of motion control

parameters, such as speed, acceleration, FIR frequency, corner and circular accuracy,

to users to adjust. Other sports-related parameters have been optimized internally

without needing user settings. The meanings of these four parameters are shown as

below:

Name

Move speed

Move acceleration

Max acceleration

FIR frequency

Circle precision

Corner precision

Introduction

Maximum speed of air moving, can be directly fill with

the maximum move speed calculated by Servo Tools software.

Maximum acceleration of air moving, can be directly fill with

the maximum move acceleration calculated by Servo Tools

software.

Maximum acceleration during processing, directly determines

the time of acceleration and deceleration of the turning

movement during cutting. Adjust by observing the torque curve

of servo.

Suppress filter frequency of machine vibration. The smaller the

value is, the more obvious the effect of suppressing the

vibration is, but which will make the time of acceleration and

deceleration longer

Arc accuracy limit. The lower the value of the arc precision, the

more obvious the limit of arc speed is.

Fit with corner precision by NURBS curve. The lower the value

is, the closer the corner is closed to sharp corner, but the

deceleration will be more significant.