Friendess CypOne Laser Cutting Control Software

68

4.6 Start and Dry Run

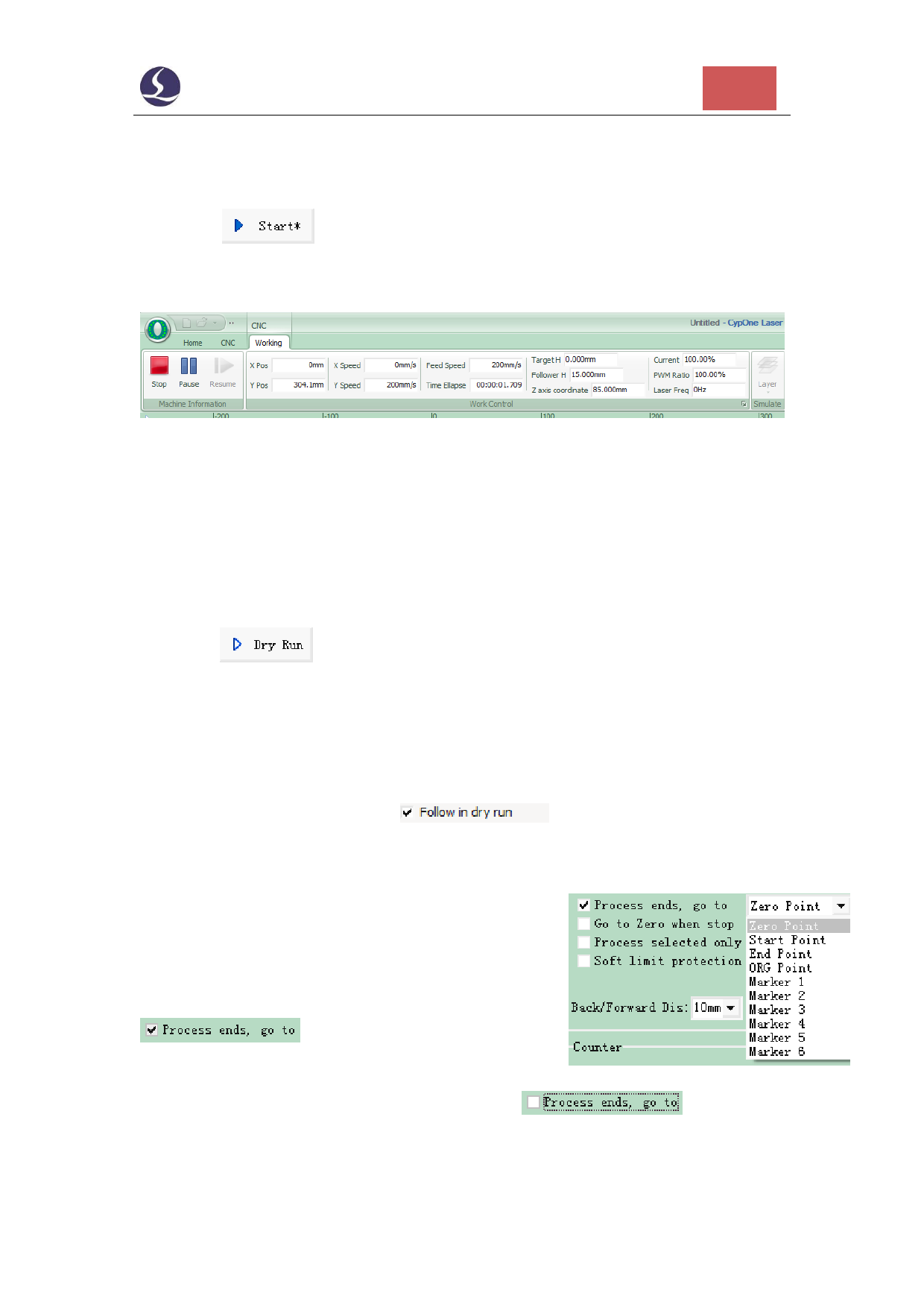

Click

on control panel start cutting, the working status bar will

display on top monitoring coordinate, speed, time and follow distance etc.

The working status bar cannot switch to others during a cutting task in case any

operations change the part drawing. If you need change parameter please pause the

cutting first then open layer parameter window modify the parameter.

Click

machine will run the tool path not turning on laser and gas,

while the speed and path are same with actual cutting. In dry run you can also execute

pause, resume, forward, backward and even locate break point, all same with real

cutting process. Dry run used to fully check and simulate the whole cutting process.

You can choose to enable

window.

in Layer > global parameter

By default laser will go to zero point after cutting

finished, if you want laser goes to other position after

cutting you can select in control panel

, options including part zero,

start position, end position, origin and marker. If

not selected,

laser head will stand where the cutting finished which equals to 'end position'. If you