Friendess CypOne Laser Cutting Control Software

63

4.1.1 Mechanic Coordinate

Mechanic coordinate is a unique existence decided by mechanism and machine

config. Coordinate created any time after return origin is consistent. If mechanic

coordinate deviated, click

in CNC tab to reset coordinate.

The definition to coordinate in CypOne is same no matter what mechanism

structure is. In CypOne definition, laser head moves right to workpiece is X+

direction, laser head moves back towards workpiece is Y+ direction. Hence the

bottom right in workpiece located smallest coordinate value, the top right in

workpiece located biggest coordinate value.

4.1.2 Software Coordinate

Mechanic coordinate is fixed, CypOne adopts

software coordinate that facilitates the production.

The direction of CypOne software coordinate

same with mechanic coordinate, only zero point

different. Software coordinate contains float

coordinate and workpiece coordinate.

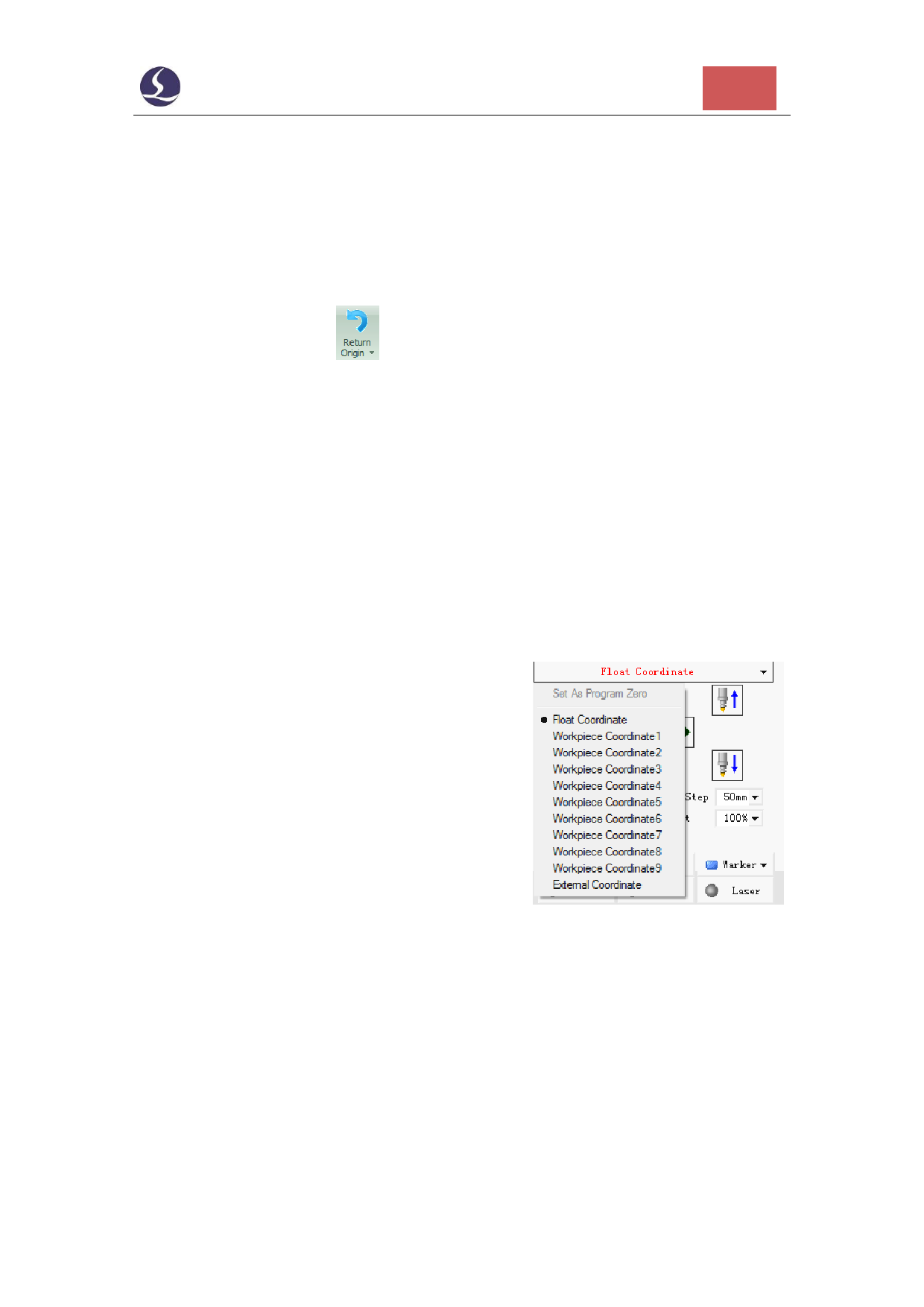

You can select coordinate on top of the

control panel, there listed 'float coordinate', nine 'workpiece coordinate' and one

'external coordinate'.

Float coordinate used in small quantity parts production, laser will start cutting

from where it stands. Execute 'Frame', 'Dry Run' or 'Start', part zero will be current

position of laser head.

User can appoint a zero point manually to each workpiece coordinate 1-9.

Workpiece coordinate applied in large quantity production, sheet material of standard