Friendess CypOne Laser Cutting Control Software

15

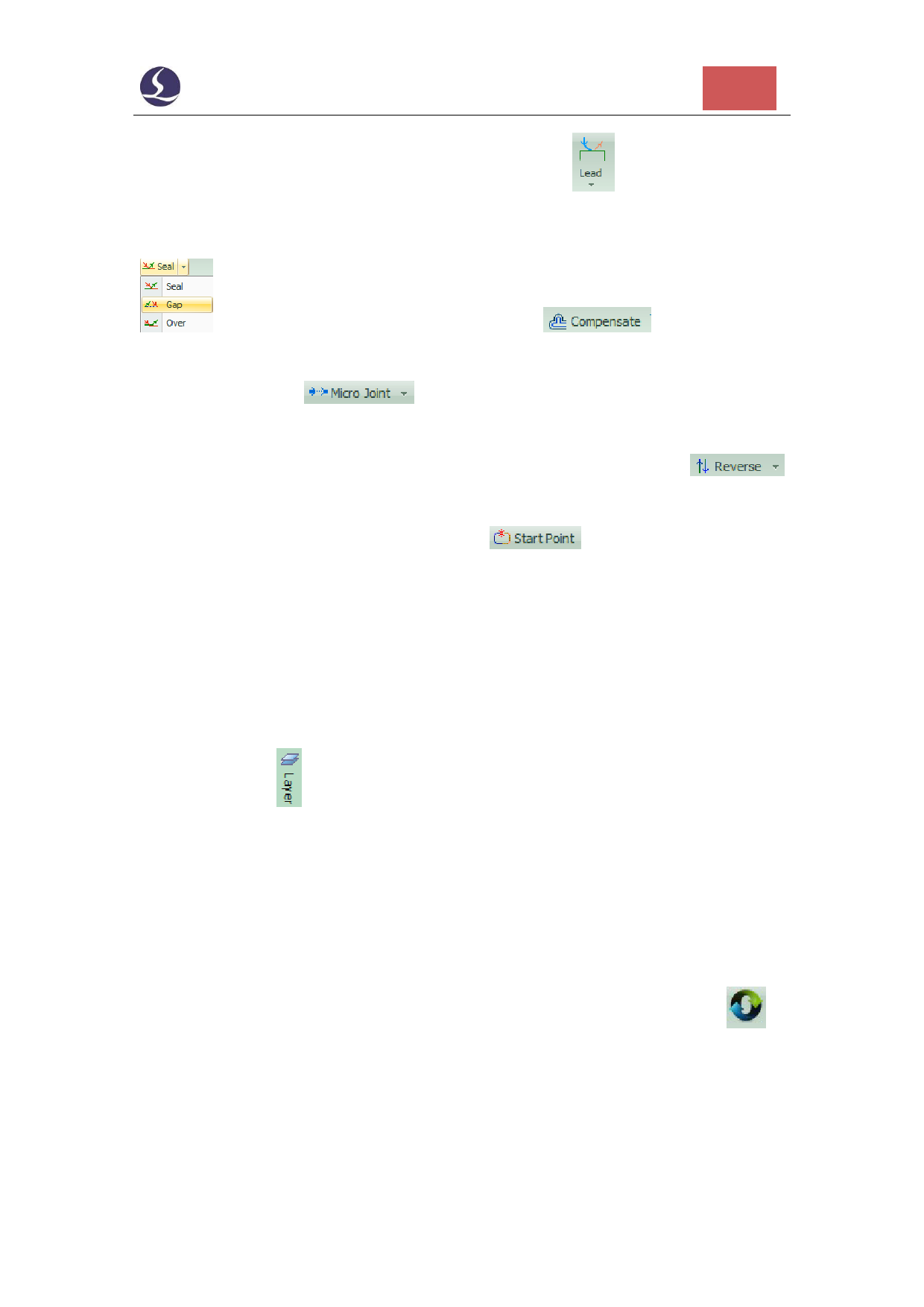

frequently used options in machining process. Click

set lead lines, click

set the over-cut, gap or seal features. Click

to add kerf width

compensation. Click

add micro-joint tags which prevent parts from

falling off the plate skeleton or tip-up collision with laser head. Click

reverse the contour (cutting) direction. Click

and point on geometry to

set start point. Or you can point outside the contour to create a lead line to the part.

You can press Ctrl + A select all drawings, then click ' ' to set lead lines by user

defined settings. Click Lead drop-down > Check Lead Line, program will check if

lead lines interfere with parts design and modify the lead line automatically.

Click button on layer tool bar to set the detailed cutting parameters. The

Layer Parameters dialog box contains almost all the parameters related to the cutting

performance.

1.4.4 Toolpath Planning

This process is to sort parts geometry and create cutting sequence. Click

on

Home > Sort will sort all geometries automatically. Or you can select in Sort drop

down menu that fit your drawing layout. The software can identify the inner/outer

relation in sorting.