CHAPTER 1 INSTALLATION

1.1.5 Servomotor Handling Precautions

1

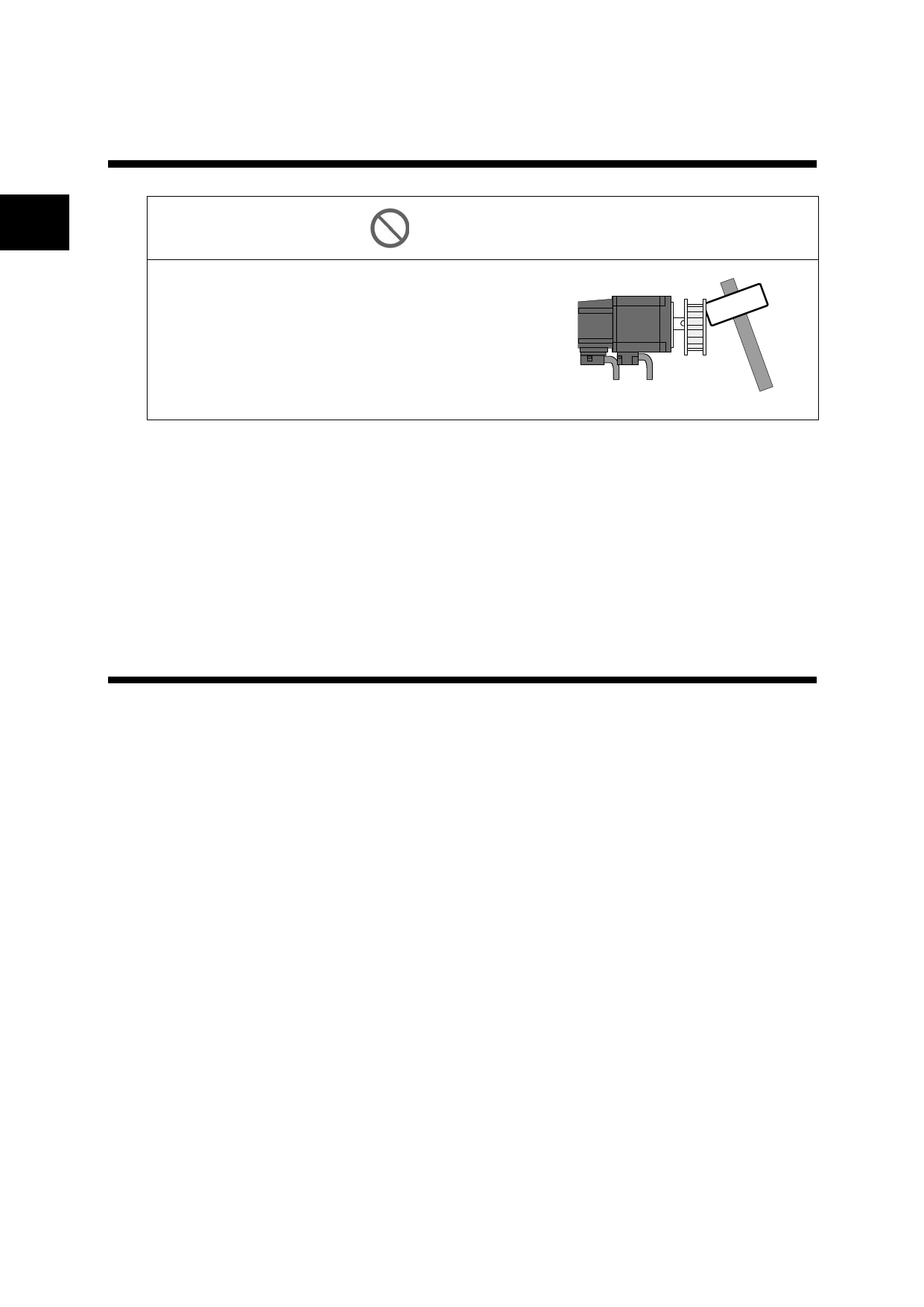

Do not hammer

Do not give a strong impact on the output shaft of the servomotor.

Otherwise the encoder inside the motor will be broken.

Align the center when connecting with the machine system. Use a flexible coupling.

Use rigid one designed exclusively for servomotors whenever possible.

Do not use a rigid coupling which does not allow errors between shafts.

Otherwise mechanical vibration will be caused, resulting in damaged bearings and/or shorter

service life.

Do not supply commercial power directly to the servomotor. It will cause burnout.

The servomotor needs to be connected to an appropriate servo amplifier when used.

For how to connect the servomotor to a servo amplifier, refer to "CHAPTER 2 WIRING."

1.1.6 Notes on Stress Given to Cable

In applications where the servomotor and machine movable part move, take measures to avoid

stress given on the cable.

Route the encoder cable and motor power cable in CABLEVEYOR.

Fix the encoder cable and motor power cable attached to the servomotor (routed from the motor)

with cable clamps or similar.

Design the radius of bend as large as possible.

Do not allow bending stress or stress caused by the self weight, at joints of the cable.

1-4 Servomotor