STANDARDS VERSUS PROPORTIONS

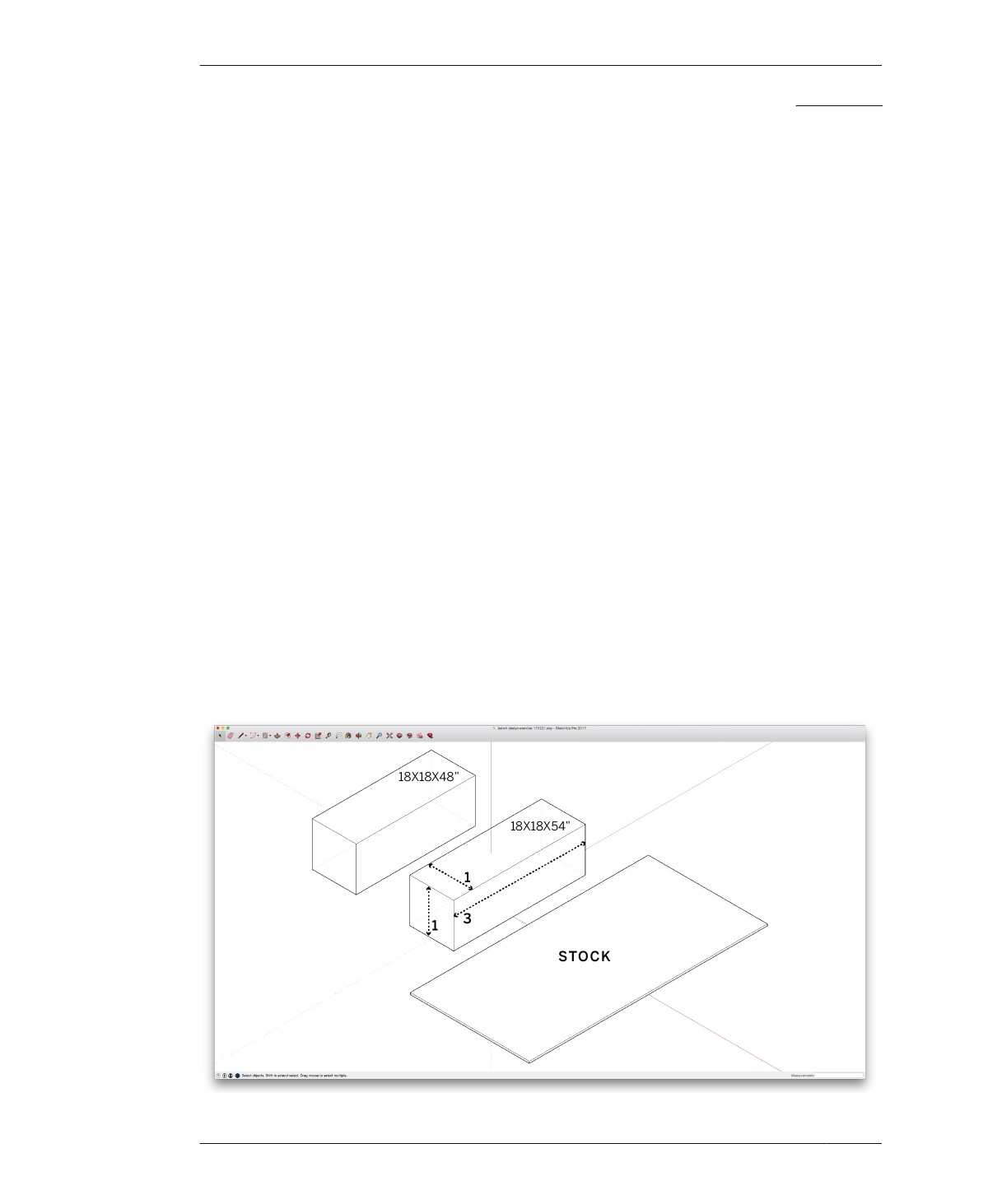

FIGURE 4-4

Refine bench massing

proportions

STANDARDS VERSUS

PROPORTIONS

Good design always meets general ergonomic

standards, and it also works within manufactur-

ing methods, material limits, and other con-

straints. After optimizing a design for function

and fabrication, you can still find ample room

for creative maneuvering during the design pro-

cess.

When we design, we like to introduce balanced

proportions at varying scales within the object,

from the overall dimensions down to the small-

est joinery details. Proportions are a kind of

shorthand that designers use for organizing

forms. Proportions, especially those found in

nature (like the golden ratio, 1:1.618), bring vis-

ual harmony into a design.

The 18” × 18” × 48” massing you just modeled

meets ergonomic and fabrication criteria.

Lengthening it, so it’s 18” × 18” × 54” (450 mm

× 450 mm × 1350 mm) gives it a perfectly pro-

portioned ratio of exactly 1:1:3, without interfer-

ing with ergonomic needs or fabrication

constraints.

REFINE MASSING DIMENSIONS

5A: Pull one end of the volume, so that the

length matches 54″, shown in Figure 4-4.

5B: Place the volume, so that the center of its

bottom face sits on the origin.

5C: Group and then place the massing onto

layer zzz_massing by clicking on the Entity Info

window and selecting the layer from the drop-

down menu. You’ll need the massing for the

next step, so leave the layer turned on.

SCHEMATIC DESIGN: MODEL

PARTS

Since the actual bench will be fabricated from

¾″ stock material, it’s sensible to use virtual

sheet goods of the same thickness to create

the bench parts. In this section, you’ll transition

your rough massing model into a bench in its

absolute simplest form—a long horizontal seat

with four vertical “legs” on each side. Next,

you’ll copy and modify the ¾″ thick stock,

aligning it with the massing block, until you’ve

created rudimentary versions of three bench

parts.

94

DESIGN FOR CNC