COMPONENTS

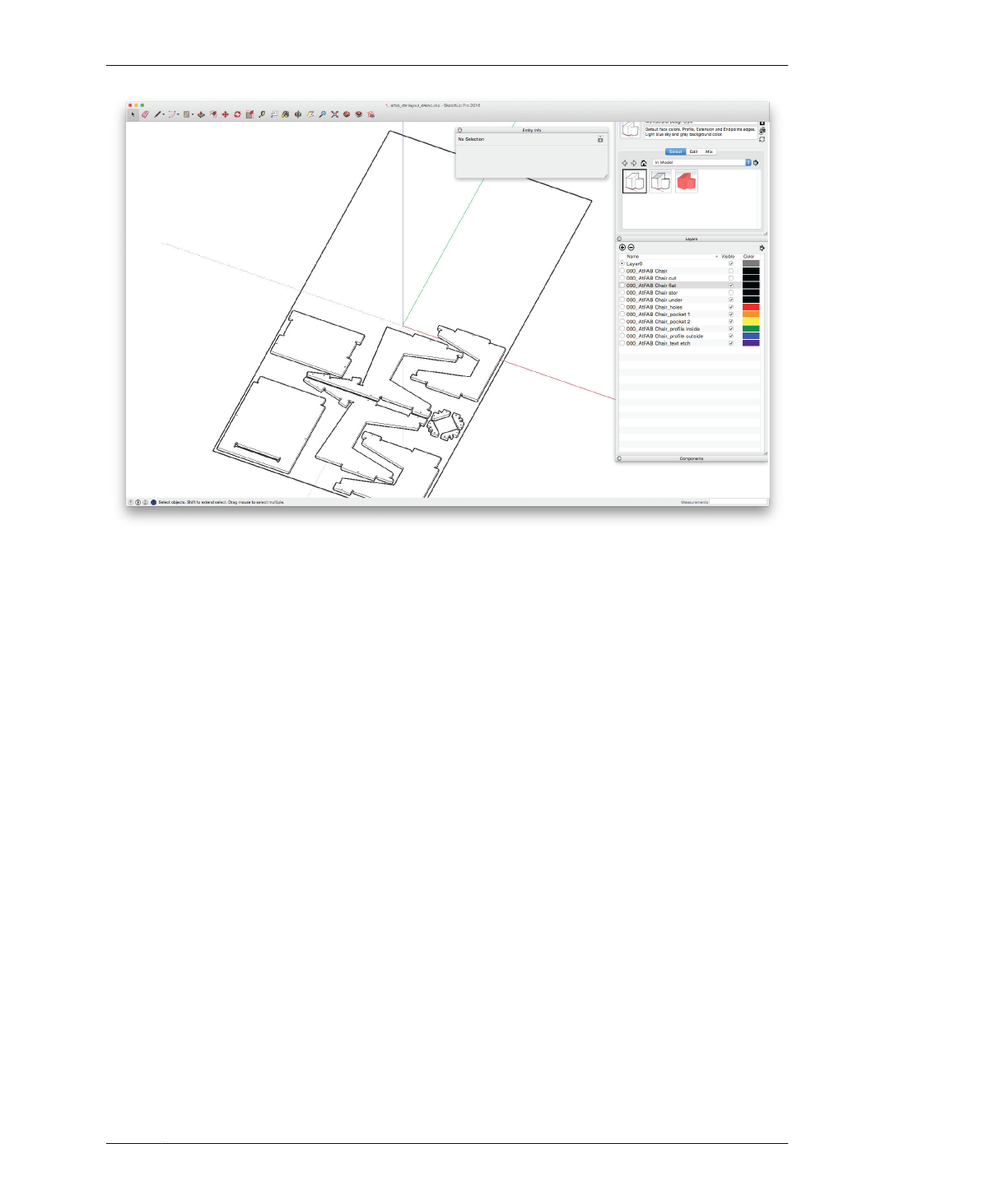

FIGURE 3-5

All chair parts flattened

and nested within the

material boundary

modeled one time, and then copied to make

the chair’s two sides and four feet. The flat-

tened copy you created in the previous step are

additional copies of those six original chair

components. Each component in this model

was named using a number, but you can name

them however you prefer.

SketchUp’s components allow you to keep a

model organized by streamlining repetitive ele-

ments. Many CAD software programs have

capabilities analogous to SketchUp compo-

nents. Some programs call components blocks

and others call them clones. When creating

components, your strategy should be to mini-

mize repetitive work that can lead to errors, so

you can maximize efficiency while maintaining

quality.

Beyond their usefulness in streamlining a mod-

eling file, components are important to the

CAD→CAM workflow of SketchUp→VCarve Pro.

Exporting components—instead of independ-

ent elements or vectors—from SketchUp into

VCarve Pro keeps a geometry’s information

intact. When preparing your file for export into

a CAM program, components also reduce repe-

tetive tasks. When you edit a component, the

copies of that component automatically

update. You’ll see this feature in action in Chap-

ter 4.

With all chair parts flattened onto the material

stock boundary, you’re ready to convert flat

parts from components into unique elements.

A unique element turns an existing component

into a new, separate component.

03/3D MODEL TO 2D PARTS

77