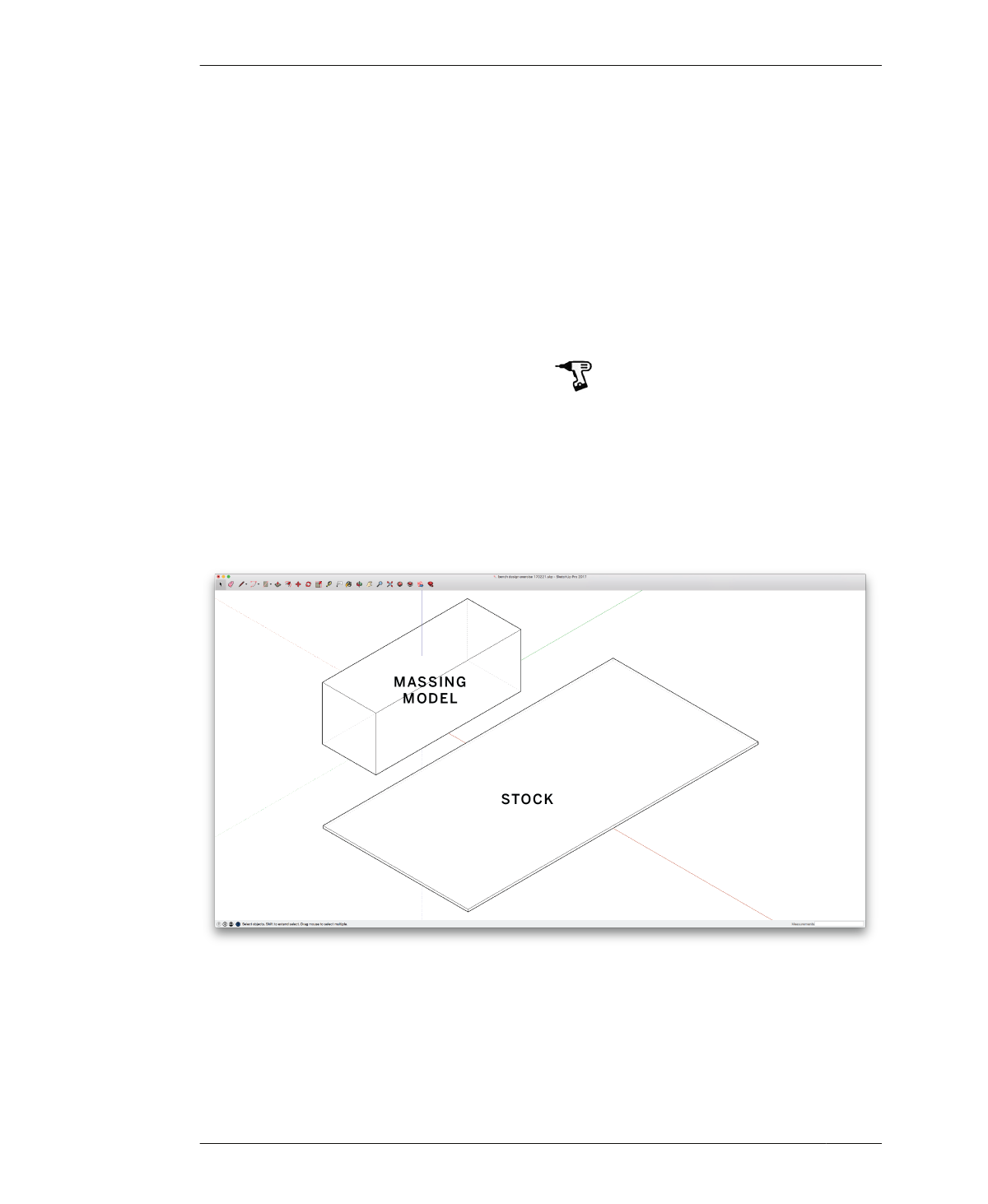

MASSING MODEL AND STOCK MATERIAL

MASSING MODEL AND STOCK

MATERIAL

In the earliest stage of designing, it helps to

start with rough, abstract elements, and then

develop the design by gradually going into

greater and greater detail. In this section, you’ll

make the first move by creating a massing

model—an abstracted solid model of the object

you’re making—in this case, a bench.

As you first make this rudimentary, three-

dimensional massing block, use your program

research as a starting point. Dimensions

derived from general ergonomic standards for

a two-seater bench are 48″ long by 18″ deep

and 18″ high (1220 mm × 450 mm × 450 mm).

You’ll also model a standard sheet of plywood,

or material stock. You’ll use this stock as the

source for creating every bench part. By model-

ing your bench parts from copies of this stock,

you’ll ensure that each has a consistent mate-

rial thickness.

You’ll use ¾″ as the material thickness of your

stock. This is a standard nominal thickness,

referred to as the variable TNOM, and used

throughout this book. Chapter 5 delves into

TNOM and working with sheet material thick-

ness.

Imperial to Metric Units

For this exercise, a standard sheet of 4′ × 8′

plywood converts to the metric standard,

1220 mm × 2440 mm. The nominal ¾″ mate-

rial thickness converts to 19 mm.

FIGURE 4-3

Material stock along-

side bench massing

92

DESIGN FOR CNC