EVOLUTION FROM THE CHAIR TO ATFAB

assembly and rotational structure emerged as

we simultaneously designed several pieces that

shared common requirements. This cycle of

testing, rethinking, and improving is an exam-

ple of iteration, and is an essential part of the

design process. As we iterated upon our frame-

work through the process of designing ever

more pieces, AtFAB coalesced into a coherent

collection with its now recognizable details and

volumetric form.

Your own design framework might consist of

common details, proportions, fabrication tech-

niques, or anything that makes sense to your

project or preoccupations. However it’s organ-

ized, you will find frameworks especially useful

in streamlining the decision-making process.

When your design task grows in scale or com-

plexity, you will inevitably face numerous deci-

sions about connecting parts and joinery.

Rather than inventing a new detail or assembly

to solve every new problem, a clear, useful

framework will guide you toward consistent sol-

utions. In aggregate, these solutions are what

will help you achieve a coherence in anything

you design.

EVOLUTION FROM THE CHAIR TO

ATFAB

The 5-30 Minute Chair was followed by other

designs, with each new piece initiating the iter-

ative refinement for AtFAB’s overall language

and system of joinery, assemblies, and struc-

tures. Through this process, AtFAB became

both a furniture collection and a library of CNC

details and techniques.

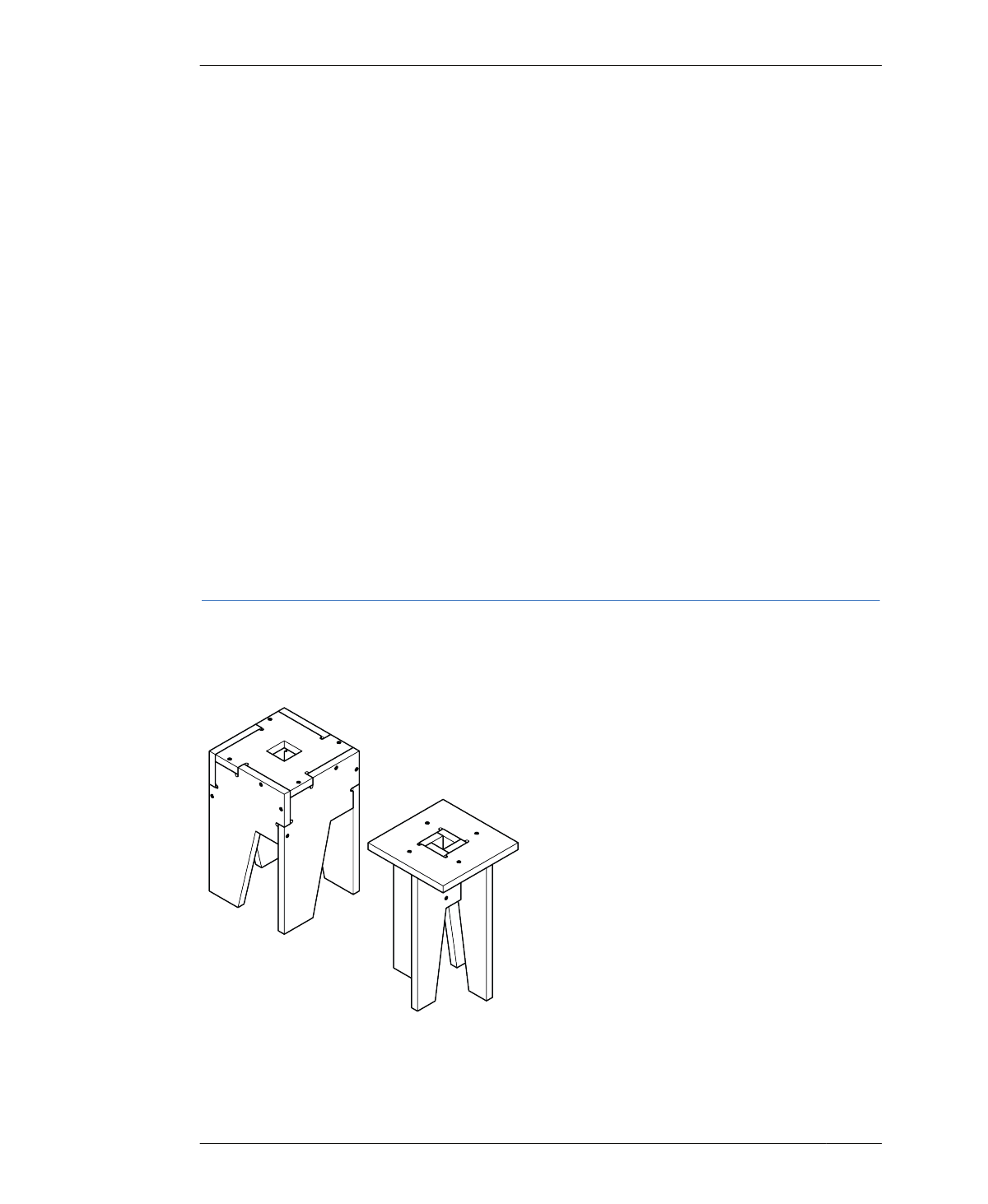

FIGURE 2-36

Rotational Stools

ROTATIONAL STOOLS

The Rotational Stools in Chapter 8 are the

smallest, simplest furniture objects in the col-

lection and in this book. Each version of the

stool has two part types: a seat part and leg

part. Four identical legs are organized into a

rotational structure, which interlocks into the

seat. The stools have a substantial amount of

joinery while using a relatively modest

amount of material, which makes them ideal

for this book’s first project and introducing

basic CNC workflow.

62

DESIGN FOR CNC