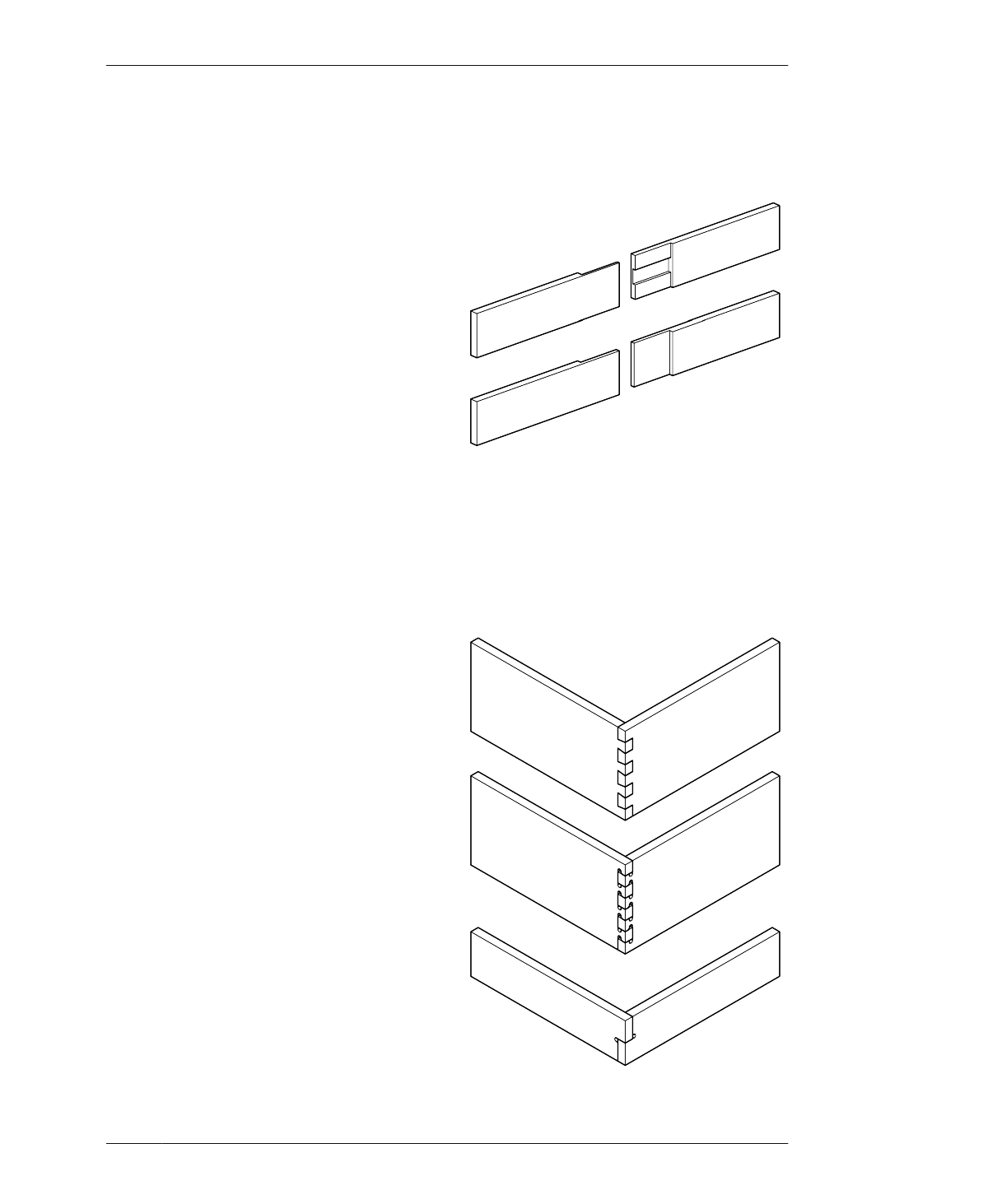

1: OVERLAP

Overlapping joints involve connecting two or

more parts lengthwise, often to achieve a

longer dimension than standard material

sizes (a process traditionally known as scarf-

ing). In its simplest iteration, the ends of each

part are pocketed to overlap one another for a

specific length. Adhesives or mechanical fas-

teners join the two parts. Woodworkers also

call this connection a simple half lap, a splice

lap, or half lap scarf.

A more precise fit can be achieved by using

a key. A keyed overlap joint is created by

pocketing a positive shape on one part, which

fits into a negatively carved counterpart on

the connecting part. There are many exam-

ples of hybrid overlap connections that use

pocketed keys that create varying degrees of

structural performance based on the shape

and connection between parts.

2: EDGE TO EDGE

Edge-to-edge connections happen at the

angled intersection of two edges. Finger and

dovetail joints are common examples of edge-

to-edge joints. Dovetails give added structural

capacity to an edge-to-edge connection by

keying the fingers. Adapting dovetail joints to

CNC projects involves profile cutting on one

hand, and sloped contour cuts on the other.

Finger (or box) joints are well suited for

CNC, as long as fillets are used to ensure a

positive connection between “fingers” on

each “hand.”

AtFAB designs keep the edge-to-edge con-

nections simple by using lazy fingers that

keep the number of interlocking fingers to a

minimum. They provide maximum structural

integrity of the finger joint while not distract-

ing from the piece as a whole.

EIGHT BASIC CNC JOINT CONDITIONS

FIGURE 2-16

Keyed and standard

overlapping joints

FIGURE 2-17

Dovetails, complex fin-

ger joints, and lazy fin-

gers

02/END MILL TO FURNITURE COLLECTION

49