WHY DO CNC PROJECTS LOOK THE WAY THEY DO?

FIGURE 1-1

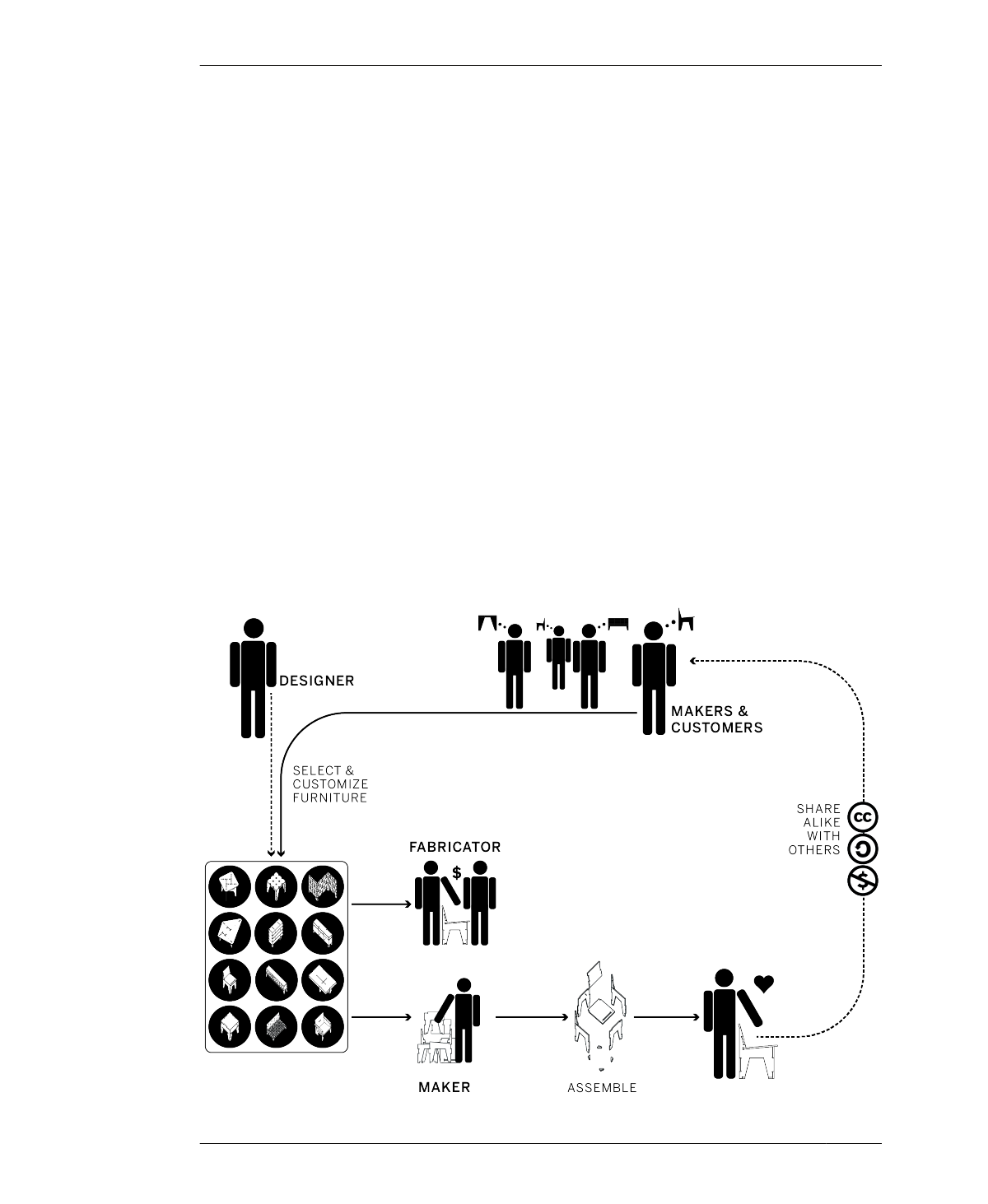

Example of a

distributed manufac-

turing ecosystem

they are quickly discarded after their shortly

useful lives are over.

For many makers, DIY is the obvious, self-

sufficient alternative to this big box dilemma.

Basic design and CNC knowledge will empower

you to make functional, delightful DIY projects

for everyday use. Designing for CNC, however,

can also make a positive impact far beyond

your own project and self-sufficiency. You can

share your digitally fabricated designs with a

network of remote makers and fabricators, and

in the process, support a new manufacturing

paradigm (Figure 1-1). When we choose to ship

information, not stuff, we are collectively

advancing a manufacturing method that has

positive consequences for the environment,

local communities, and for democratic econo-

mies.

WHY DO CNC PROJECTS LOOK

THE WAY THEY DO?

“Total design is nothing more or less than a process

of relating everything to everything.”

—George Nelson

This often-cited quote by mid-century architect

and designer George Nelson is a fitting explan-

ation of why many CNC designs share a unique

“look.” Good design will inevitably transcend

style and aesthetics, when designers relate

everything to everything. For centuries, furni-

ture design has been optimized around tools,

material, technique, function, and aesthetics.

Hardwood furniture was built with integral

structural joinery, which was often expressed to

celebrate the quality, integrity, and craftsman-

ship of the object. This can be seen in the dove-

30

DESIGN FOR CNC