TOOLPATHS

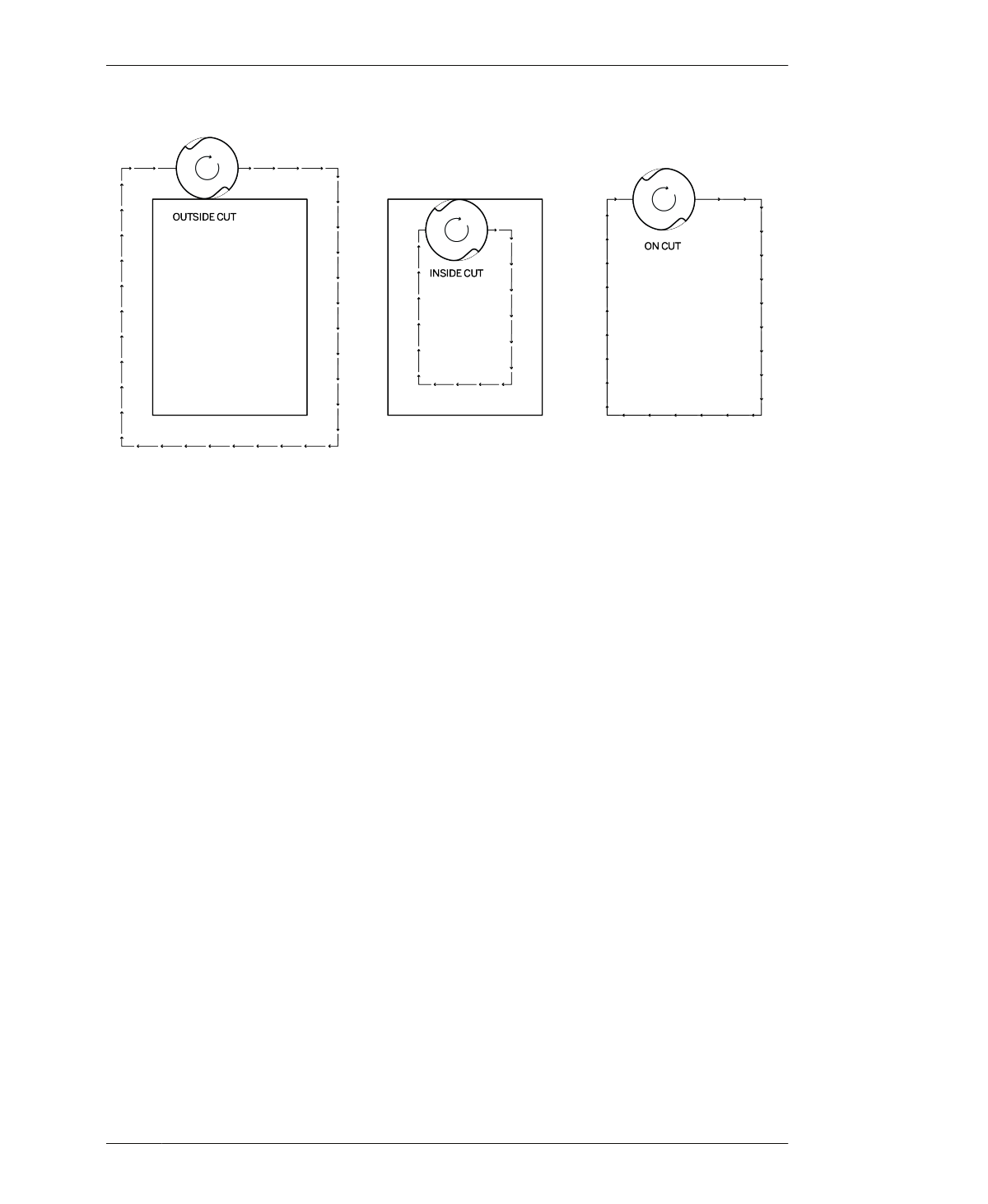

FIGURE 2-11

Profile toolpaths can

cut on, outside, or

inside a line, which

changes the position of

the kerf and the dimen-

sions of the part

are three different ways to make the cut: you

can choose to cut on the line, outside the line,

or inside the line. No matter which side of the

line you cut, this is the toolpath to use when

you want to completely cut out a part.

We’ve already established that end mills have a

physical diameter that removes material when

cutting, creating a kerf as the material is

removed. Figure 2-11 shows how the kerf is

positioned for each type of profile toolpath.

The “on cut” view in Figure 2-11 shows the tool

cutting directly on the line. This type of tool-

path works well for decorative details, but is not

used for machining accurately sized parts.

When the tool cuts on the line, it creates a kerf

(slit) approximately equal to its diameter—but

half of the kerf (equal to the radius of the tool)

is positioned inside the part.

If you’re using a ¼″ tool, the total kerf is ¼″.

But—because the tool is cutting on the line,

you’re actually cutting into the part—removing

an eighth of an inch! If your parts are designed

to scale, then you need to cut outside or inside

the part lines.

OUTSIDE PROFILE

This is the most commonly used toolpath type

because it creates a true part outline. As you

can see from Figure 2-11, outside profiles only

remove the material outside the part line, main-

taining dimensional accuracy. As end mills have

a physical diameter that creates an equally

large cut and kerf, cutting outside profiles feels

similar to outlining a thick pattern block with a

very thick marker tip.

INSIDE PROFILE

This type of toolpath cuts inside the part line.

Because it only removes material inside the

part line, it is often used to make through cuts

for features that occur inside a part, like a slot.

02/END MILL TO FURNITURE COLLECTION

45