SUBTRACTIVE MACHINING

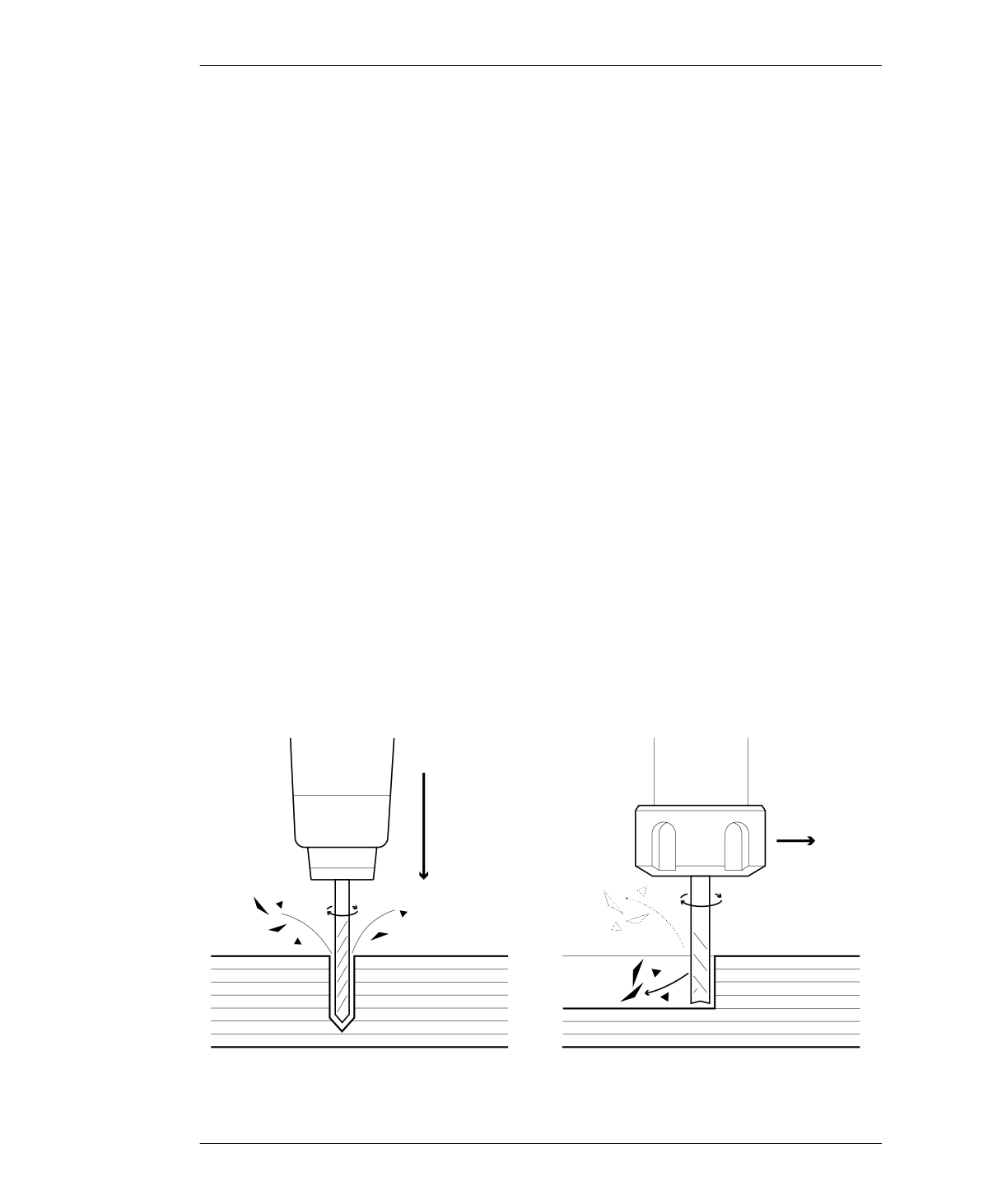

FIGURE 2-1

Twist drill plunging

axially, end mill cutting

laterally

metries, each engineered to create different cut

types and finishes in specific material types.

DRILLING

You’ve probably used a hand drill, or are at least

familiar with the concept of drilling. The most

common type of drill bit, a twist drill, is

designed to cut axially, with a pointed tip that

plunges directly into the material. As the drill

rotates a cutter around a central axis, the bit’s

sharp tip bores into the material and the chips

are spiraled upward through the helical flutes,

or grooves, that wrap around the tool, shown in

Figure 2-1.

Drills (and their bits) are tools with a singular

purpose: to create holes. The side flutes on a

drill bit are dull; only the tip has cutting surfa-

ces, one on each side of its center axis.

CUTTING LATERALLY

Like drill bits, the flutes of most end mills also

have sharp bottom edges that allow them to

plunge, but end mills can do many things that a

drill bit cannot. In addition to plunging, end

mills also have the ability to cut side to side, or

laterally. That’s because the helical flutes on

the sides of an end mill have teeth, or sharp

cutting edges.

Unlike a twist drill, the end mill’s sharp bottom

edges don’t end in a single, protruding central

point. When an end mill can plunge (most can),

it is said to be center-cutting, or end cutting,

because its flutes have sharp edges that extend

around the bottom of the tool, meeting at an

indented point in the center (as shown in

Figure 2-1), so the end mill can cut laterally.

THE INSIDE CORNER PROBLEM

As Figure 2-3 illustrates, a rotational cutter can

never completely carve out an interior angle.

The rounded corners left behind match the

tool’s radius.

When cutting out parts that have both “inside”

and “outside” 90-degree corners, as shown in

Figure 2-2, the outside corners are cut cleanly,

with their sharp right angles intact—but the

inside corners are radiused—and excess mate-

rial is left behind. As the end mill’s diameter

38

DESIGN FOR CNC