SUBTRACTIVE MACHINING

increases, so does the amount of material left

behind in the corners.

This is why our friend’s slotted bookcase parts

didn’t fit together as intended; the excess cor-

ner material in both the horizontal and vertical

slots made a flush fit impossible.

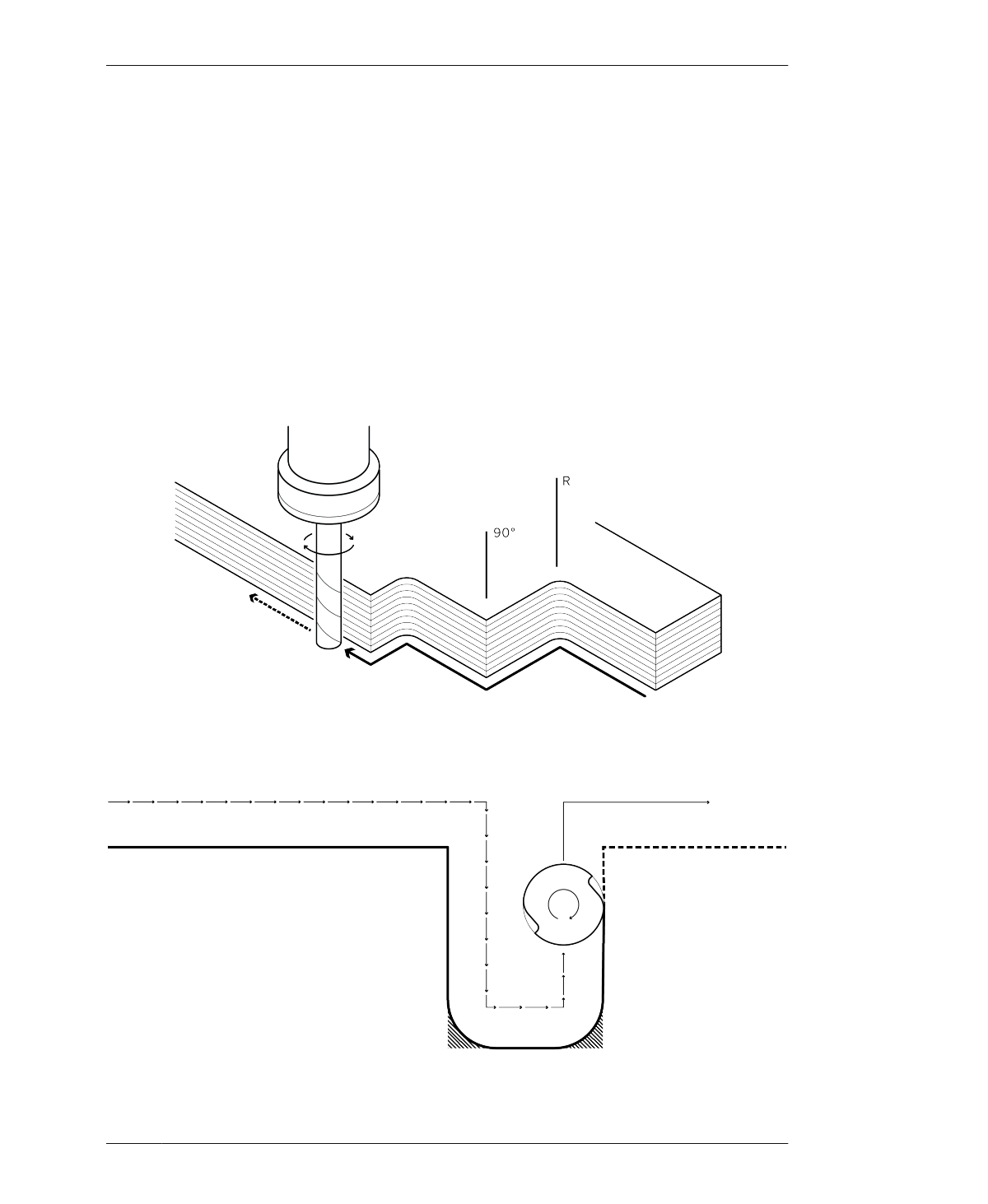

When a 90-degree inside angle is used to cre-

ate joinery intended to slot together tightly—

the leftover inside corner material prevents the

cross-pieces from fitting together snugly—both

the top and bottom parts stick out (Figure 2-4).

When we began to design our first CNC furni-

ture pieces, our friend’s sledgehammer inci-

dent was fresh in our minds. We sketched

different shapes that would create a flush, 90-

degree fit between two parts. Illustrated in

Figure 2-5, these sketches resulted in the snig-

let, a corner detail design that pulls the tool

deep into the inside angle, removing the radi-

used corner.

FIGURE 2-2

The inside corner has a

sharp, 90-degree angle

FIGURE 2-3

A round tool cannot fill

an inside corner

02/END MILL TO FURNITURE COLLECTION

39