FILLETS

FILLETS

The sniglet is a type of fillet. A fillet is a design

feature that rounds off a corner. Although fillets

can be added to both outside and inside cor-

ners (and can even refer to adding material to a

corner via welds), when it comes to cutting flat

parts, it’s imperative to add fillets to the interior

corners if you want your joinery to fit properly.

If you come from a woodworking background,

you may have had to resort to extensive hand

labor to remove the residual inside corner

material your manual router left behind. When

working with a CNC, it’s far easier, efficient, and

elegant to add fillets to your files and let the

machine do the work.

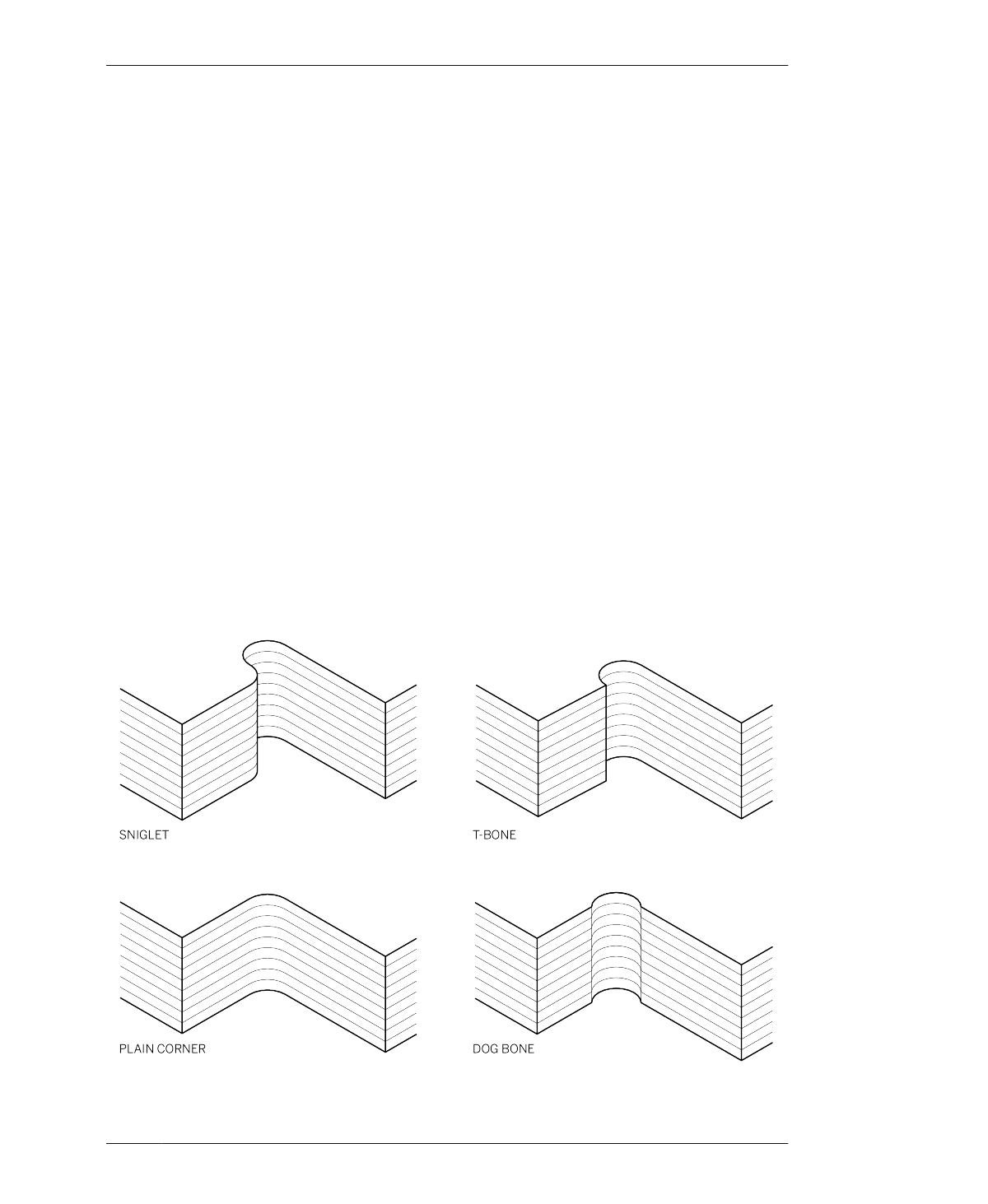

In addition to the sniglet introduced earlier,

there are two other commonly used fillet solu-

tions: dogbones and t-bones, shown in

Figure 2-6. These fillet types are named for

their appearance. When a dogbone fillet is

added to both sides of a slot, the slot takes on a

cartoonish, dogbone- or t-bone-like shape.

TOOL DIAMETER MATTERS

Regardless of type, fillets are tool diameter

dependent; their size and shape are deter-

mined by the diameter of the end mill used to

cut the parts. For context, the projects in this

book use both ¼″ (6mm) and 1⁄8″ (3mm) diam-

eter tools.

Because you’re hardcoding the tool size into

your design, it’s a good practice to draw fillets

slightly bigger than necessary—110% larger

than the actual tool diameter works well. This

ensures that if the drawing needs to be scaled

down slightly, the end mill will still fit onto the

inside corners. Scaling is covered in detail in

“Scale Your CAD File” on page 133.

FIGURE 2-6

Machined fillet types

02/END MILL TO FURNITURE COLLECTION

41