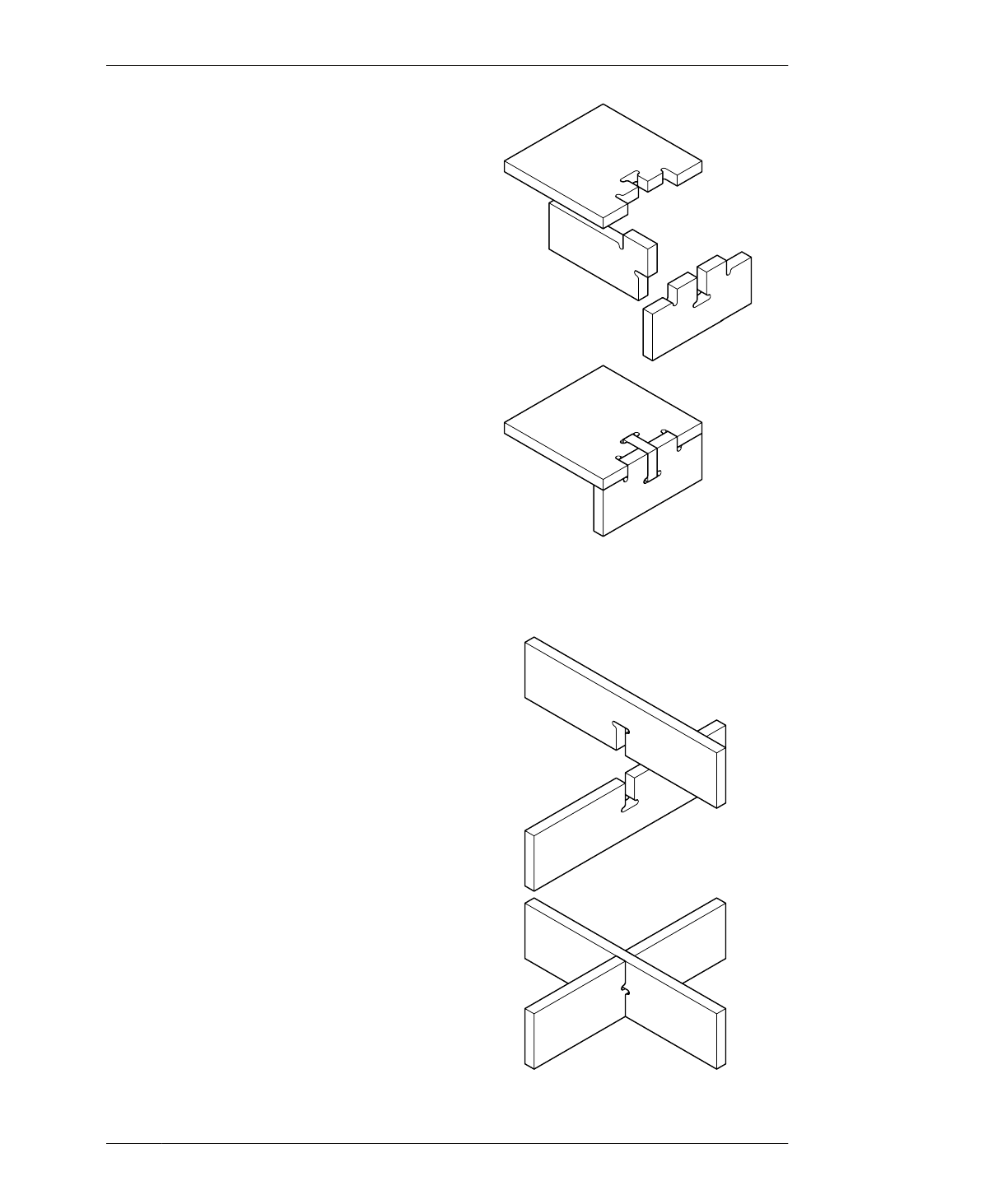

5: END TO FACE TO EDGE

An end-to-face-to-edge connection occurs

when a third part sits atop an end-to-face

connection, creating a tremendously strong,

integrated joint. A combination of the end-to-

face and edge-to-edge, this connection could

also be called a compound finger or com-

pound slot and tab connection.

Using an end-to-face-to-edge connection

requires some extra design and planning to

ensure that it has a flush alignment, is struc-

turally viable, and can be physically assem-

bled. Close attention must be paid to the

respective lengths of fingers, slots, and tabs.

EIGHT BASIC CNC JOINT CONDITIONS

FIGURE 2-20

An end-to-face-to-edge

connection, or “com-

pound finger”

6: THROUGH

A through connection (also known as a cross-

lap) aligns intersecting slots on x and y cross-

pieces, so that each appears as if it’s passing

through the other. The slots in each piece are

ideally the same depth at the midpoint, which

preserves a maximum effective load carrying

area.

The real power of these connections

comes when they are used serially to produce

a frame or two-way structure. With larger

assemblies, you will get added structural per-

formance by placing upward-facing slots on

the short-span members. This way the short-

span members are effectively “carrying” the

longer spanning components. When locating

slots on framing members, be sure to avoid

“weaving,” which would make the structure

physically impossible to assemble.

FIGURE 2-21

These crosspieces are

an example of a

through connection

02/END MILL TO FURNITURE COLLECTION

51