PARTIAL PROTOTYPING LARGE PROJECTS

PROTOTYPING CASE STUDY

In the design process, prototypes can be indispensable,

especially when designing and fabricating a large or

complex project with many unknown factors.

We had such a project a few years ago when we were invi-

ted by WeMake for a Maker Residency in Milan, Italy. We

designed an Open Source Wunderkammer, a large CNC-

fabricated partition to display dozens of 3D-printed won-

ders, downloaded from the internet. The project was

large, requiring eight sheets of plywood, and a lot of cut-

ting time. We relied on both scale prototypes and partial,

full-scale prototypes at different stages in its develop-

ment.

Right before final fabrication at WeMake, we worked with

our hosts to fabricate a corner of the Wunderkammer at

full scale. It was an elaborate test piece cut using the

actual material. We selected a corner of the piece that

was the most complex intersection of the frame and

infill. Going through the toolpathing, fabrication, and

construction gave us the chance to evaluate the material,

machine settings, and assembly process. Knowing that

the most complex portion of the design worked, we had

confidence that the entire job would go smoothly.

At home in our studio, we designed and digitally modeled

the project, and in advance of our arrival in Italy, we fabri-

cated a scale prototoype out of aircraft plywood with our

desktop CNC router. This physical version helped us

evaluate the design, check parts, and make small adjust-

ments to our digital model. We brought the scale proto-

type along with us to Italy, where it became quite helpful

in communicating the design and planning the fabrica-

tion and assembly process with our hosts and collabora-

tors.

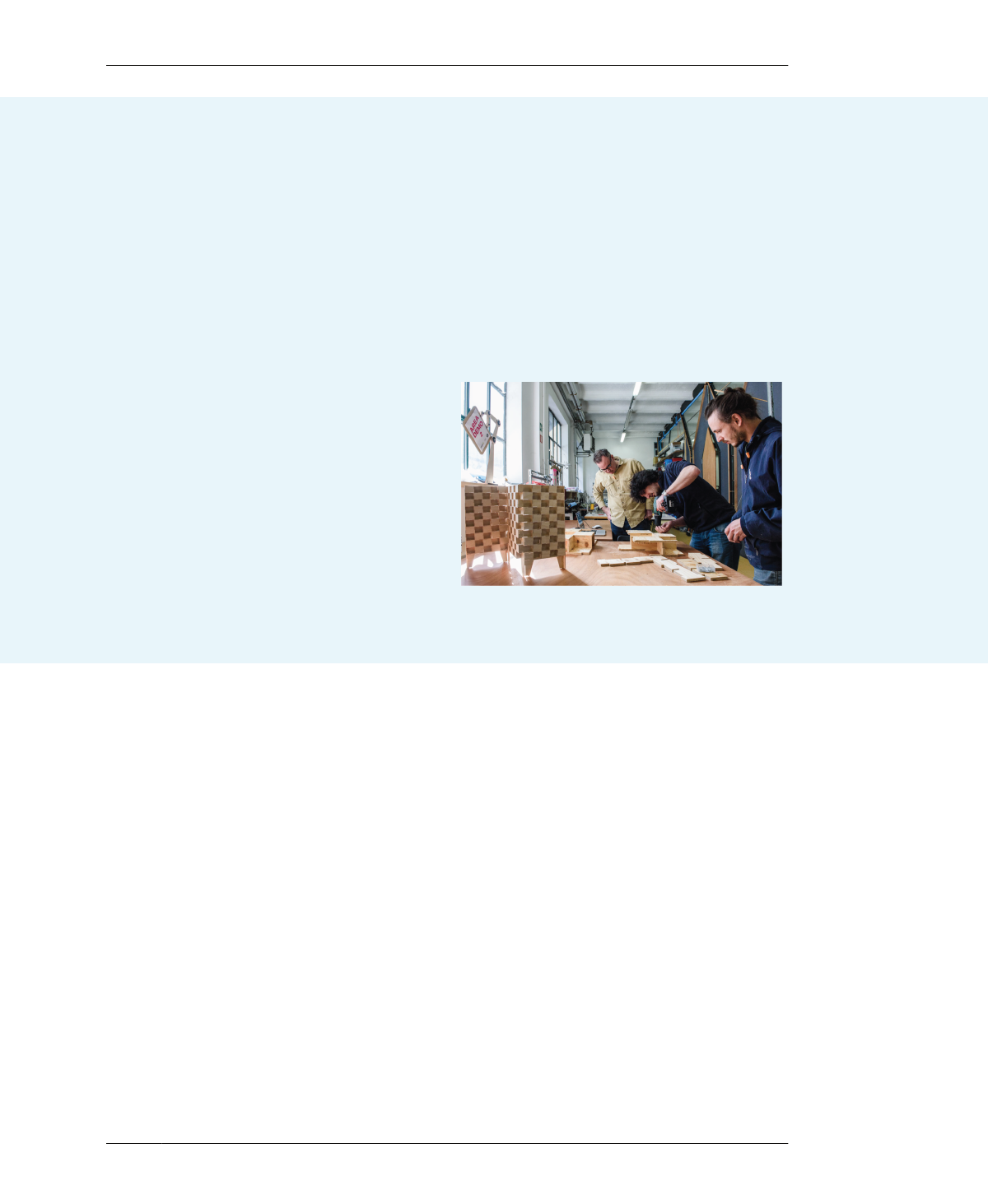

FIGURE 16-3

Working with both a

scale prototype and

partial full-scale proto-

type at WeMake in

Milan (photo credit:

Stefano Pedrelli)

SCALE CAD FILE & TEST PIECE

04: Open AtFAB_SCR.skp → Scale all 2D pro-

files on the toolpathing layers by S.

05: Open AtFAB_SCR_TEST.skp → Scale the

test piece profiles by S (see “Partial Prototyp-

ing: Using a Test Piece” on page 212).

PARTIAL PROTOTYPING LARGE

PROJECTS

Cutting seven sheets requires a significant

commitment of both CNC time and sheet

material, so it’s well worth sorting out material,

fabrication, and assembly details in advance.

For a large project like the Cellular Screen, both

scale and partial prototypes can prove useful at

different stages in the process.

As outlined in “Scale Prototypes” on page 137,

a scale prototype (test piece) helps you under-

stand the screen design in detail. But more

importantly, it also helps you plan a fabrication

and assembly process that unfolds more effi-

ciently. Laser-cutting a scale version of the Cel-

lular Screen requires you to go through a mini-

fabrication process, so you have a better idea

of what to expect when you go full scale. A

small prototype also serves as a very effective

tool for communicating with others and prac-

ticing the steps of staging parts and handling a

complex assembly sequence.

16/CELLULAR SCREEN

311