MEASURE & SCALE

MANAGE PARTS

Having a system to identify individual parts

greatly simplifies the process of making a large

project. Labeling parts in the digital file and

physically marking them as they come off the

machine helps you keep track as you move

through the digital workflow and into fabrica-

tion, finishing, and assembly. Labeling allows

you to handle parts methodically and consis-

tently, and it also keeps you from overlooking

or losing a part. Beyond just keeping track,

marking the screen’s numerous similar parts

also streamlines the process of putting it

together.

When you open AtFAB_SCR.skp, you’ll find

seven sheets laid out with part numbers loca-

ted on each part. You can manually mark the

cut parts with these numbers by applying

removable adhesive labels, just before the parts

are removed from the CNC machine bed. Alter-

natively, you can draw discrete part numbers in

CAD and program a toolpath to etch a number

directly into each part.

MEASURE & SCALE

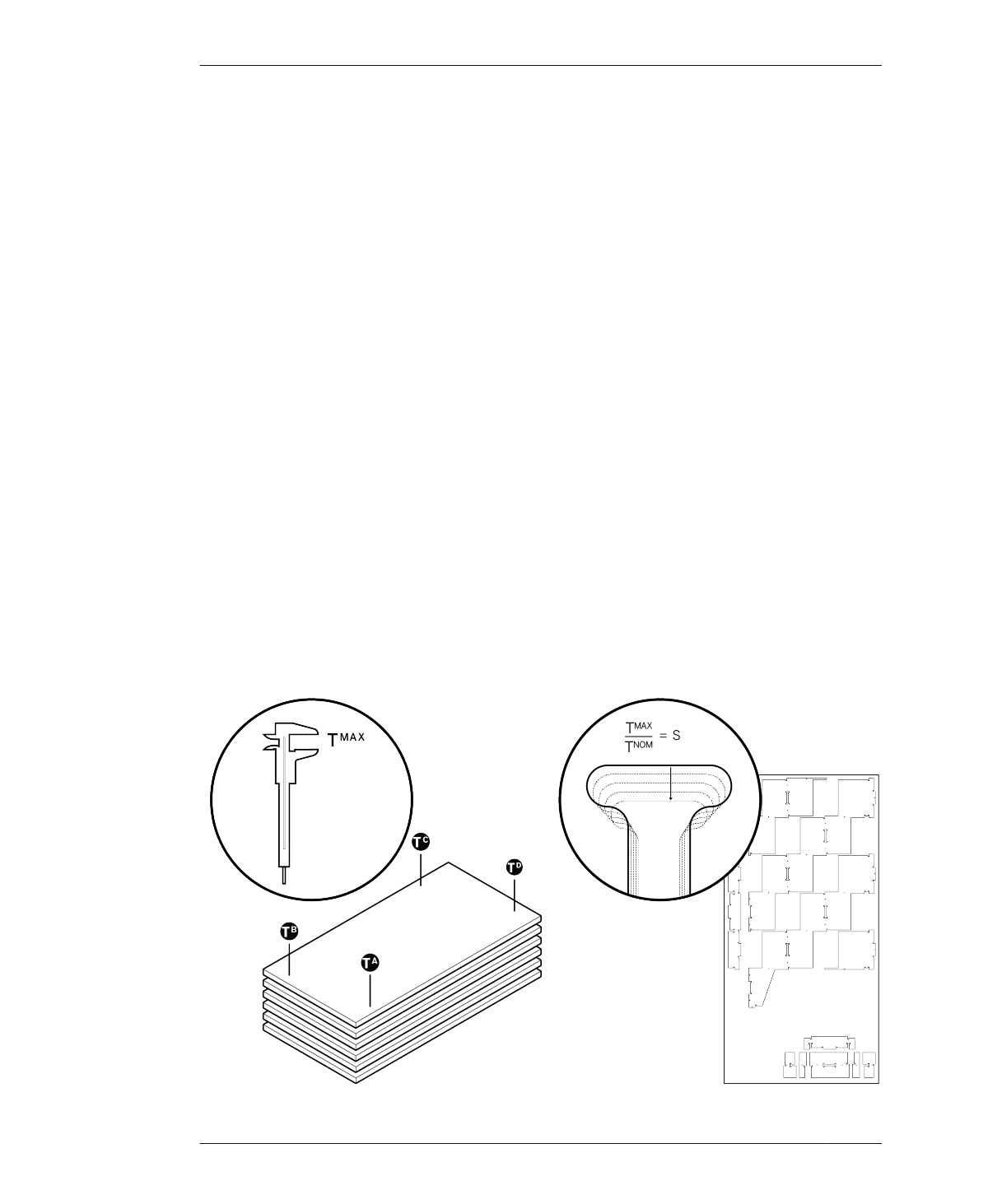

01: Once you have your 1/2″ thick sheet mate-

rial in the shop, review “Measure Your Materi-

als” on page 132. Thoroughly measure each of

the seven sheets to get TA, TB, TC, TD, as illus-

trated in Figure 16-2.

02: Record these measurements for each sheet

and calculate TMAX, your actual material thick-

ness. While measuring 28 times seems abso-

lutely tedious, the extra effort allows you to

find any dimensional variation that might

cause trouble for your joinery later on.

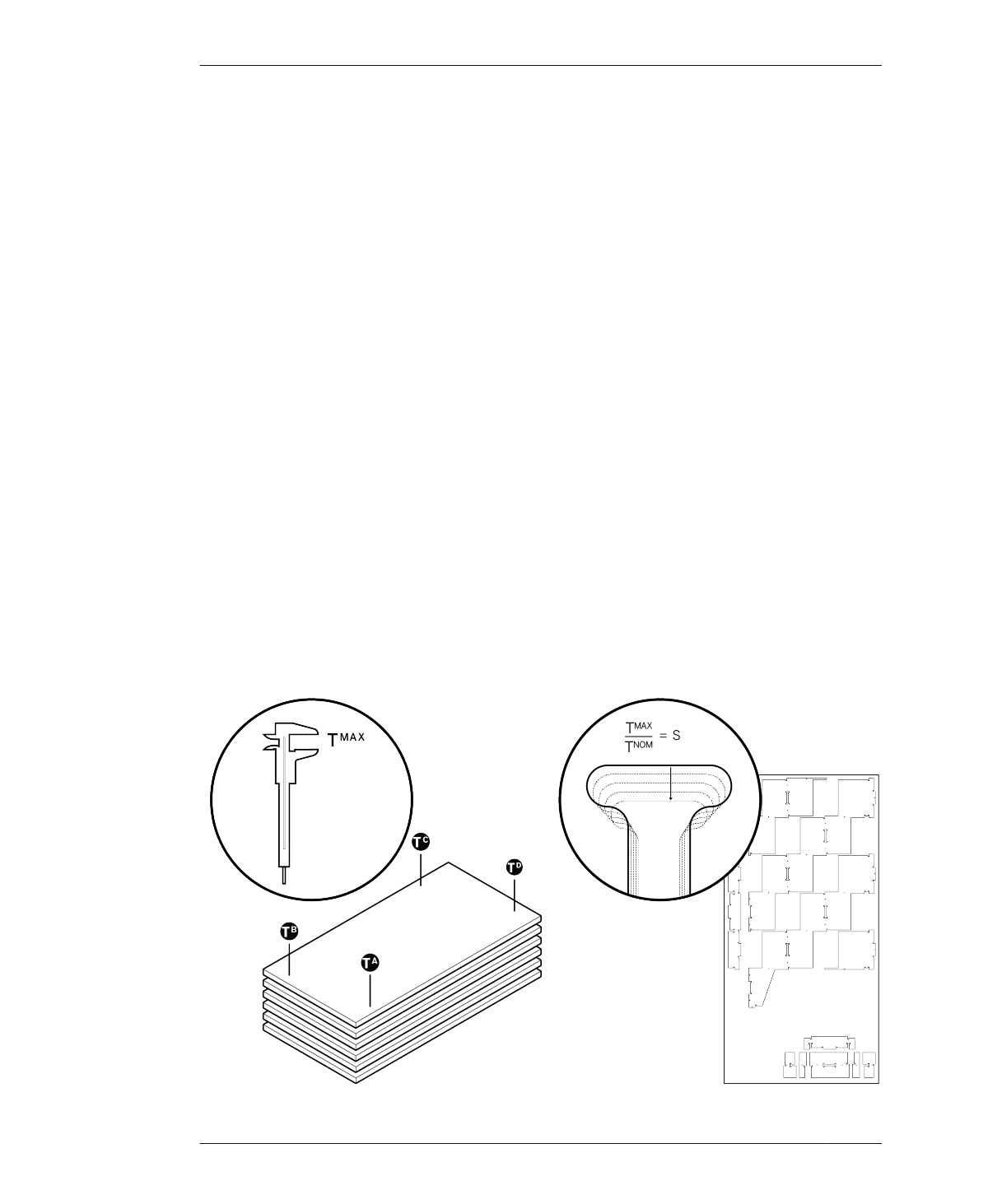

03: Once you’ve identified TMAX, refer to “Scale

Your CAD File” on page 133 on how to divide

TMAX by TNOM to define your file-scaling per-

centage (S). The TNOM for the Cellular Screen

is ½″ (12mm).

FIGURE 16-2

How to measure and

scale the Cellular

Screen file

310

DESIGN FOR CNC