ADJUST AND CUT CREDENZA

The top and bottom cabinet parts, which con-

tain pocketed grooves for the sliding doors, add

some complexity to your job planning. These

parts are asymmetrical and will only fit into

place one way, so it’s critical to mill the grooves

into the back face of the material.

06: Before cutting, place sheet material onto

the CNC bed with the finish facedown, so the

tool can mill pocket cuts for the doors into the

back face.

07: Cut your credenza parts in the correct

sequence.

08: As you take parts off of the machine, clean

off the machine dust from each part with a

nonabrasive brush, and file or lightly sand the

part edges as necessary. Thoroughly remove

sawdust or other residue from the pocketed

grooves, as this will prevent doors from sliding

smoothly.

09: Store credenza parts carefully, either laid

out flat on a blanket or stacked with paper, fab-

ric, or foam layers between parts. Keep the

thinner and more fragile door parts separated

from the much larger and heavier cabinet

parts.

10: Follow the material and coating manufac-

turer’s instructions (or what you learned in

your earlier evaluations of the test pieces) as

you finish your test piece. Let all parts dry/cure

completely before staging for assembly.

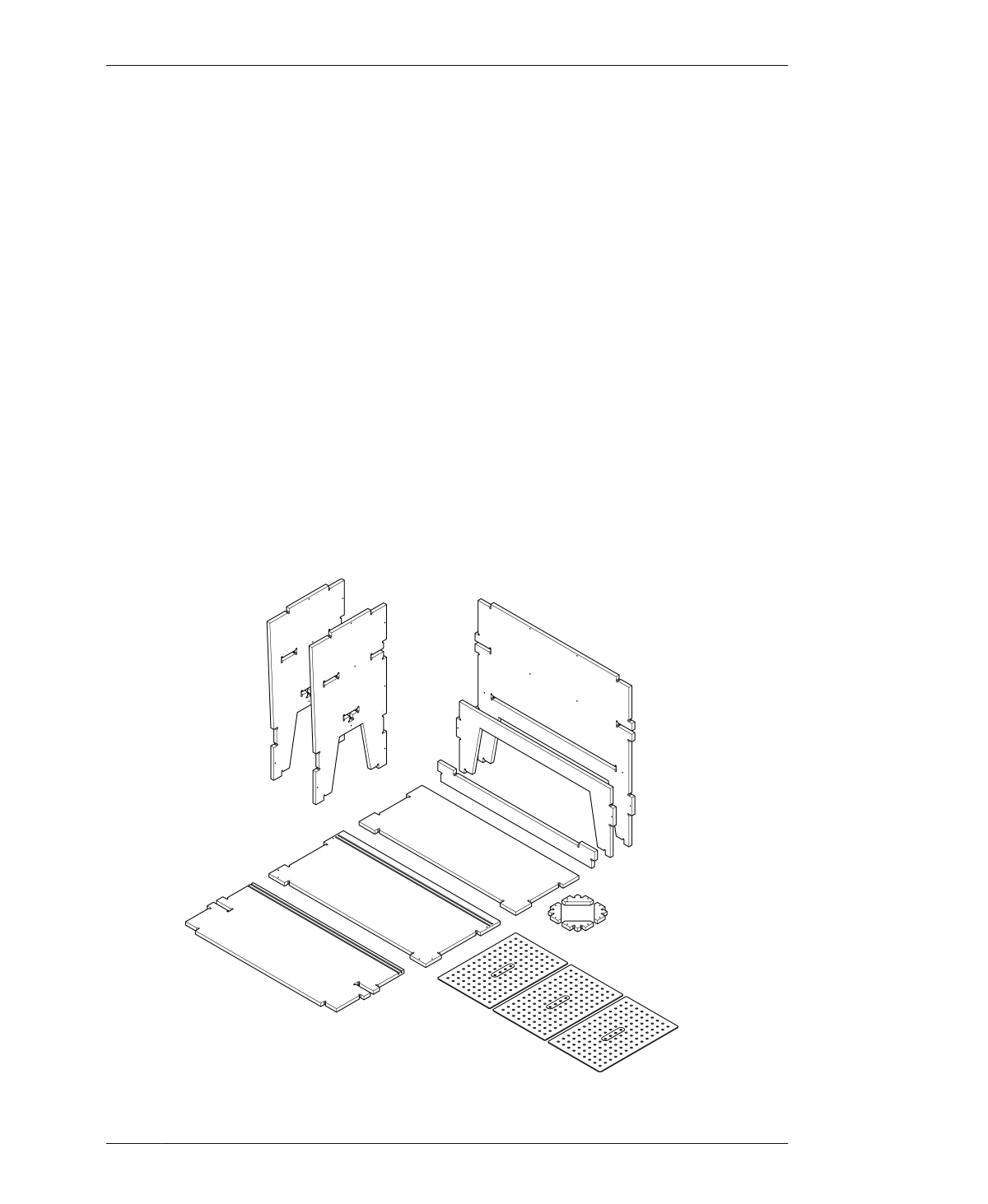

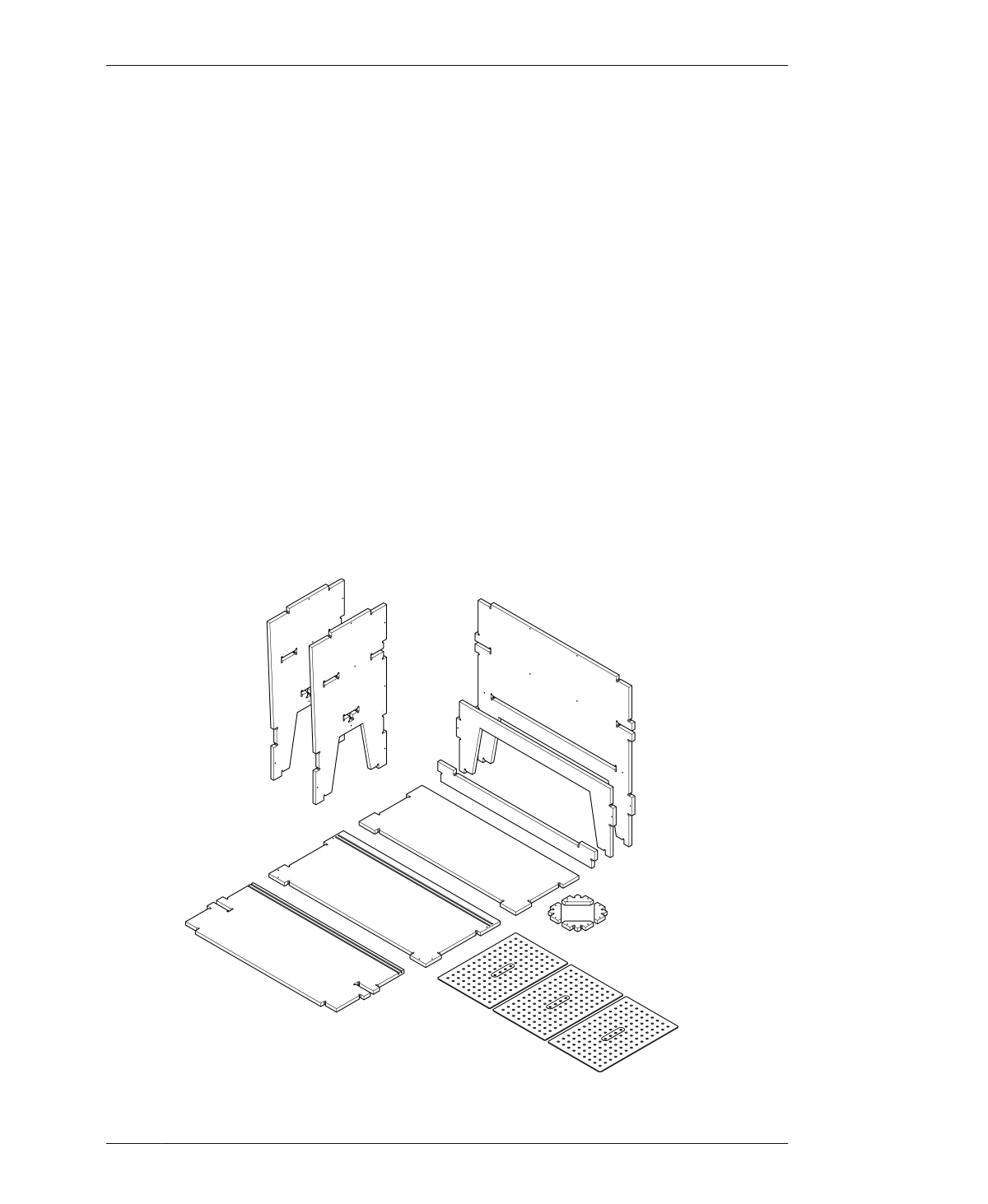

FIGURE 15-8

Credenza parts

15/POKE CREDENZA

303