CREATE THE PARTIAL PROTOTPYE

14: Start by cutting the doors first, using the

smaller end mill for the thinner material.

15: Follow by changing to the next sheet, cut-

ting fastener holes and pockets first.

16: Finally, change the end mills to cut the

outer profiles last. Also remember that cutting

inside cuts, pockets, and holes prior to cutting

the overall shape will keep details aligned

within the parts.

With so many overlapping conditions and

steps, it really helps to rely on VCarve’s anima-

tion and simulation tools. These tools help you

thoroughly evaluate the cutting sequence and

check your work prior to saving the toolpath

operations for fabrication.

To ensure that paints or coatings don’t affect

the fit, finish both cabinet and door parts with

the same methods you plan to use for the

project. For the door panels, this allows you to

ensure that materials and finishes are com-

patible for smooth sliding.

CUT, ASSEMBLE, AND EVALUATE

17: Save the toolpath operations for fabrication,

cut out the parts, assemble the test piece, and

evaluate the fit.

18: Clean sawdust and residue out of all

grooves.

19: Assemble the test piece, including the slid-

ing doors.

20: As parts come off the machine, dust them

off and file or lightly sand the edges as neces-

sary. Store your parts carefully.

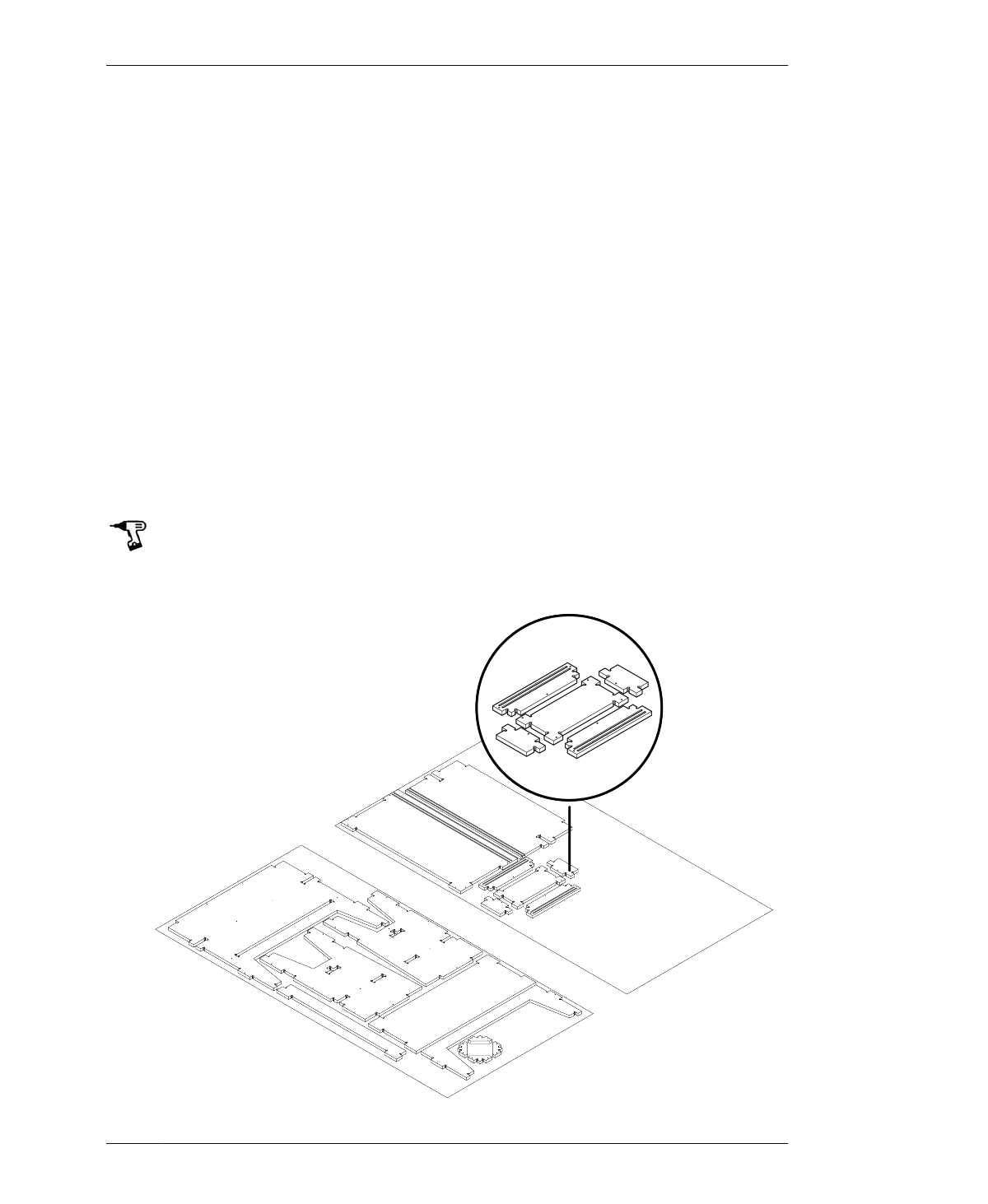

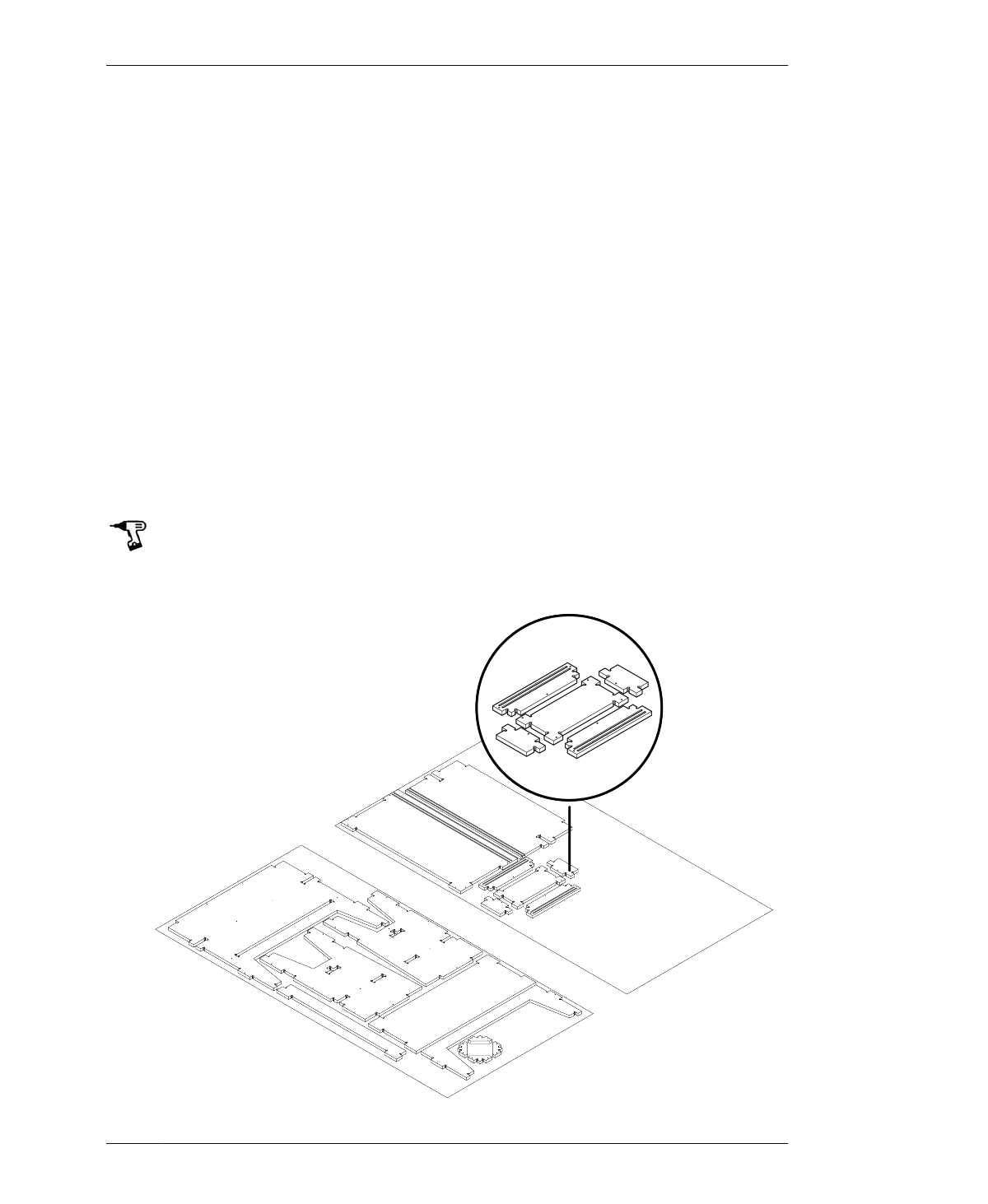

FIGURE 15-6

Credenza parts and

test piece laid out on

cut sheets

15/POKE CREDENZA

301