CREATE THE PARTIAL PROTOTPYE

09: First, define toolpaths for the outer cabinet

of the credenza.

◦ Outside toolpaths cut around the outside of

parts.

◦ Define an inside toolpath to cut the slot in

the cabinet sides. (This will be applied later,

when you cut the actual credenza.)

◦ Define the holes toolpath to make inside

cuts for the fastener holes, using a smaller

end mill.

10: Add a pocket toolpath to cut the sliding

door slots on the top and bottom parts. Use

the smaller diameter end mill and set the

pocket cut depth to TMAX/2.

PREPARE TOOLPATHS FOR SLIDING

DOORS

11: For the doors, define toolpaths for outside-

doors and inside-doors. If pocketing or carving

your own patterns, prepare those additional

toolpaths.

12: Assign the smaller diameter end mill to the

inside-door and outside-door toolpaths. Define

additional toolpaths, if exploring other kinds of

end mills or toolpath settings.

CUT SEQUENCE

Refer to “Toolpath Order” on page 195 and

“Create Pocket Toolpaths” on page 242 on cut-

ting pockets and keeping details intact by cut-

ting fastener holes, inside cuts, and pockets,

prior to cutting outside profiles.

13: As you program the cutting sequence, think

about coordinating your end-mill changes with

material changes to make the process more

efficient. For the credenza and its test piece,

you can use the same end mill that cuts fas-

tener holes and pocketed slots for cutting the

door panels from thinner material.

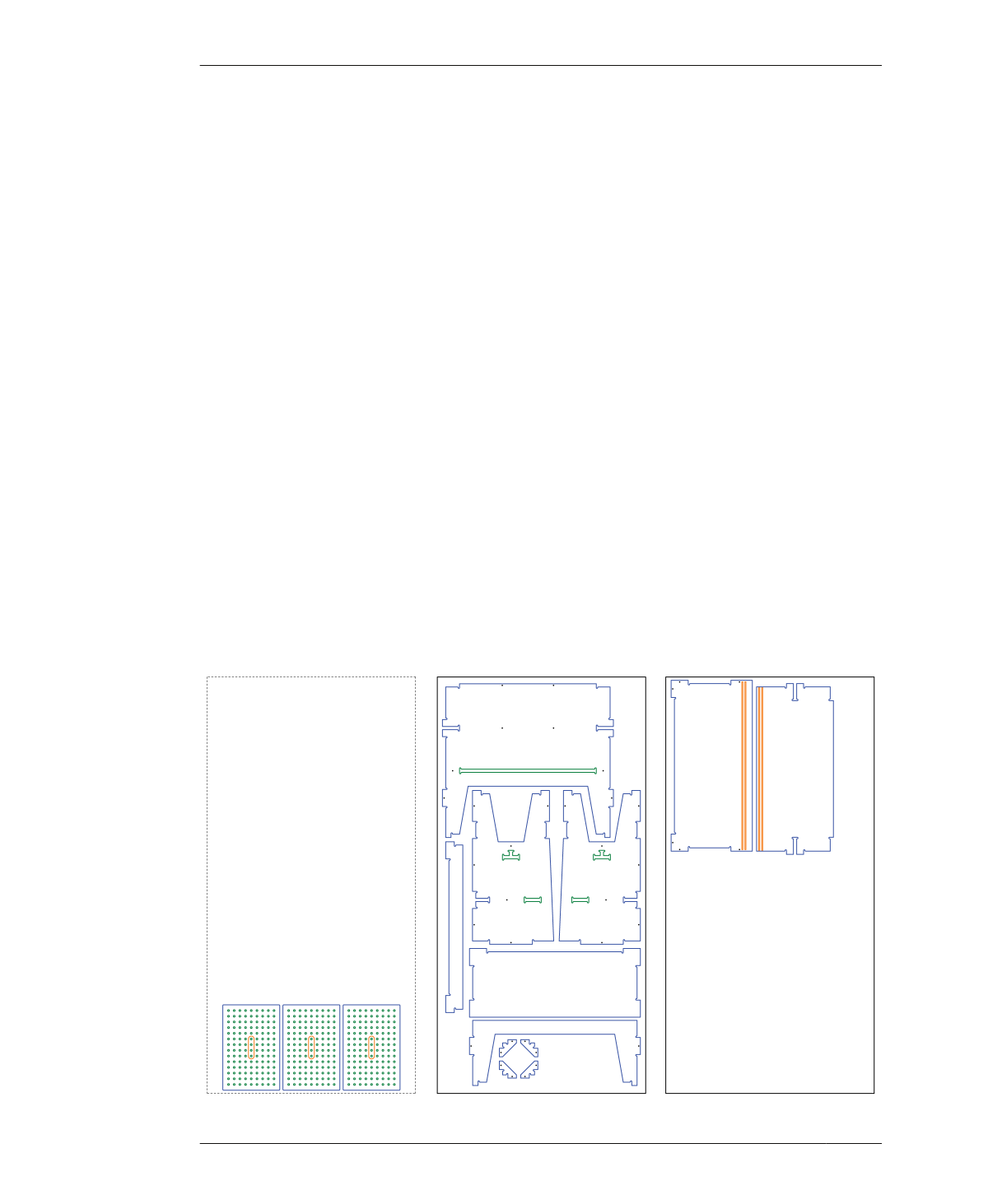

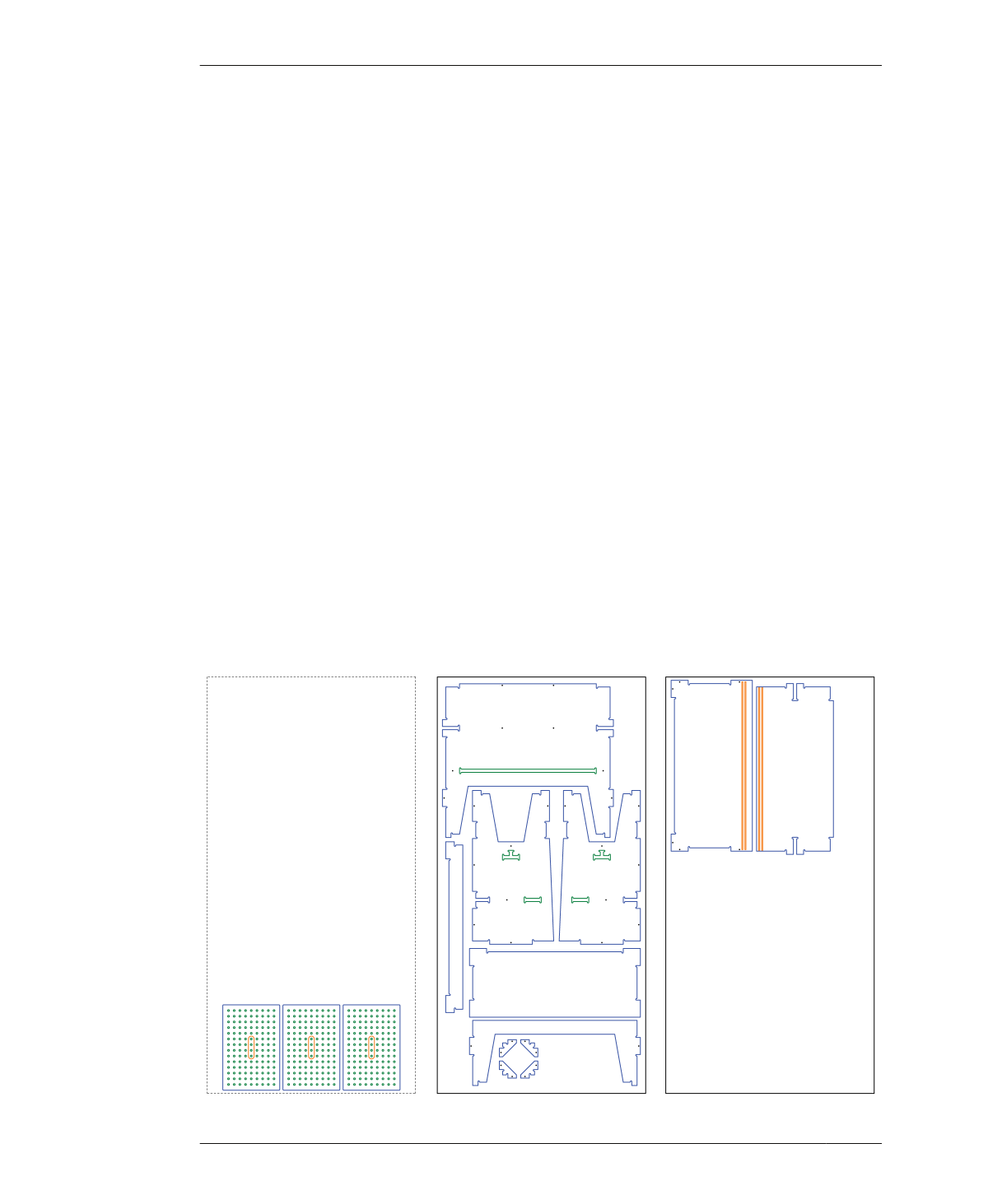

FIGURE 15-5

Toolpaths in the cut file

300

DESIGN FOR CNC