USING THE ONE TO SEVERAL TABLE APP

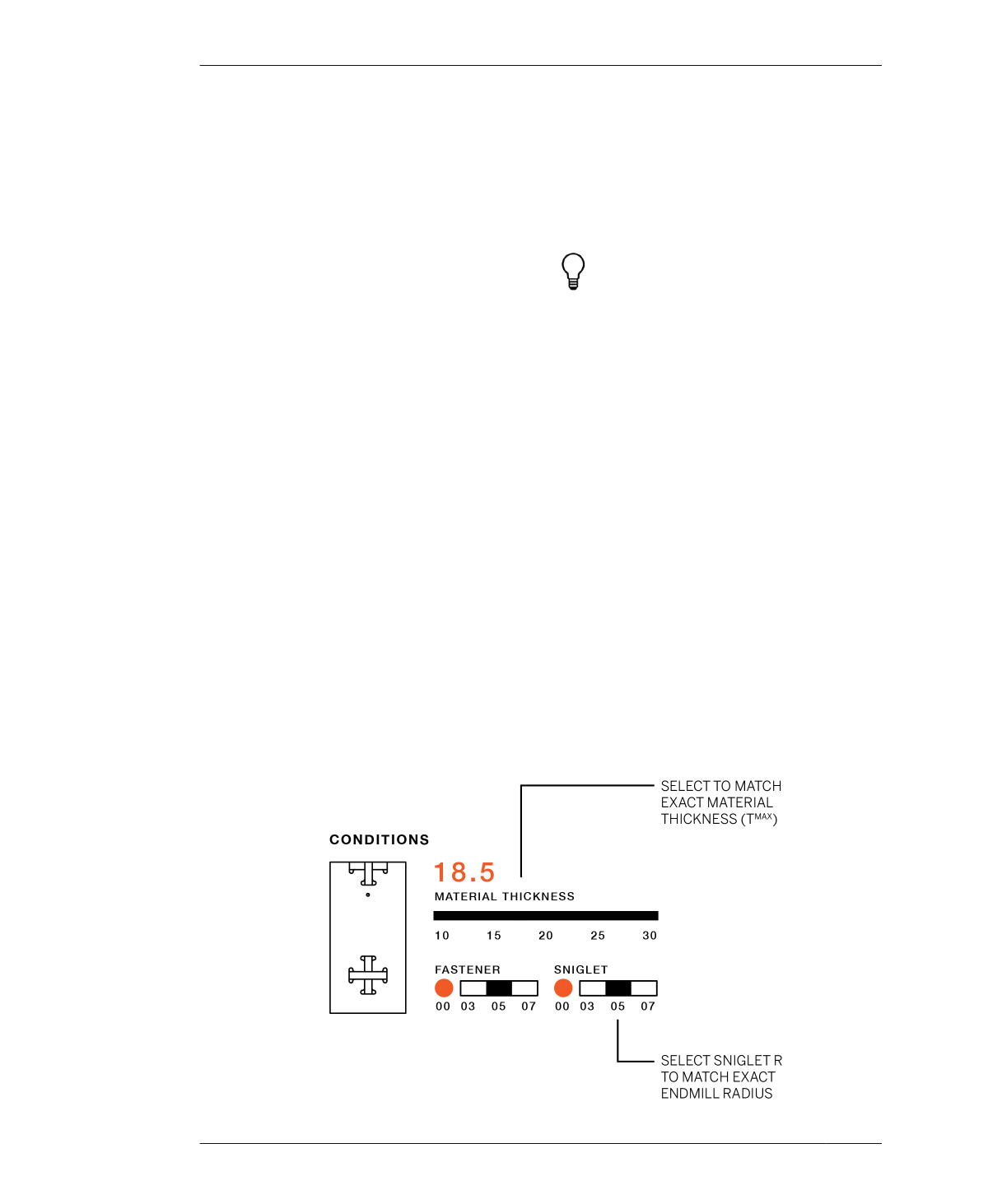

FIGURE 13-4

Match app settings to

material (TMAX)

08: Set height

This setting has two options. The lower height

is standard desk/table height. The taller option

is standard standing height. Select the option

that best matches your program.

09: Proportions

• Free is the default option that allows the

length and width to remain independent.

• Select locked, if you would like to preserve a

particular ratio between the length and width

measurements.

• Select modular if you would like to set a

golden ratio of 1.618 between the length and

width.

SET OVERALL CONDITIONS

The parametric app has a set of controls, called

conditions. These operations work alongside

the dimensional transformations to affect all

the table parts.

10: Set Material Thickness

This important control allows you to generate a

file with parts that match the maximum thick-

ness of your material. Move the material thick-

ness slider to match TMAX.

The app allows you to produce cut files that

precisely match sheet material thicknesses,

while skipping the scaling step in “Scale Your

CAD File” on page 133. The setting also makes

it possible to produce a cut file, using a wide

range of material thickness.

Refer to Appendix B for options and tips on

sourcing materials. However, if you’re consid-

ering materials other than ¾″ plywood,

ensure that your material choice has a

strength to weight ratio that can handle the

span of your table.

11: Set fastener diameter

This control changes the hole diameter to

match a particular fastener diameter. If you’re

using standard fasteners, keep this at the

default setting.

12: Set sniglet diameter

This control adjusts the size of every sniglet to

your CNC tool, like a laser cutter, water jet, or

smaller diameter end mill. Keep this at the

default setting, unless you plan to use a differ-

ent machine or end mill.

13: Select grommet

If the table will accommodate computers or

equipment, you can select the grommet hole

268

DESIGN FOR CNC