TOOL DIAMETER

You’ve already seen that each project cut file

works with a common, ¼″ end-mill diameter,

and that every sniglet on each part accommo-

dates this standard diameter.

However, what if you have access to a laser cut-

ter or water jet, with a beam diameter that’s

much finer than an end mill? Or perhaps you’re

working on a scale prototype that needs a

smaller tool, or maybe you’d simply like to use

a different diameter end mill. A parameter that

controls tool diameter and changes the sniglet

size to accommodate alternatives to the stan-

dard makes it easy to modify files for different

processes or scales, giving designers and fabri-

cators the flexibility to tailor a cut file for the

machine that’s available.

MATERIAL THICKNESS

After making any of the projects in this book,

you have spent considerable effort scaling the

profiles in your CAD file (in “Scale Your CAD

File” on page 133) to match your material thick-

ness TMAX. A parameter that controls material

thickness spares you that effort, by adjusting

the size of every slot and tab to accomodate

TMAX. Unlike scaling, this method precisely

maintains your overall part dimensions

(explained in “Scaling, Offsetting, and Parame-

ters” on page 134). As with the tool diameter

parameter, this capability gives makers and

fabricators the flexibility to customize a cut file

to work with any material that’s locally avail-

able.

ATFAB’S PARAMETERS

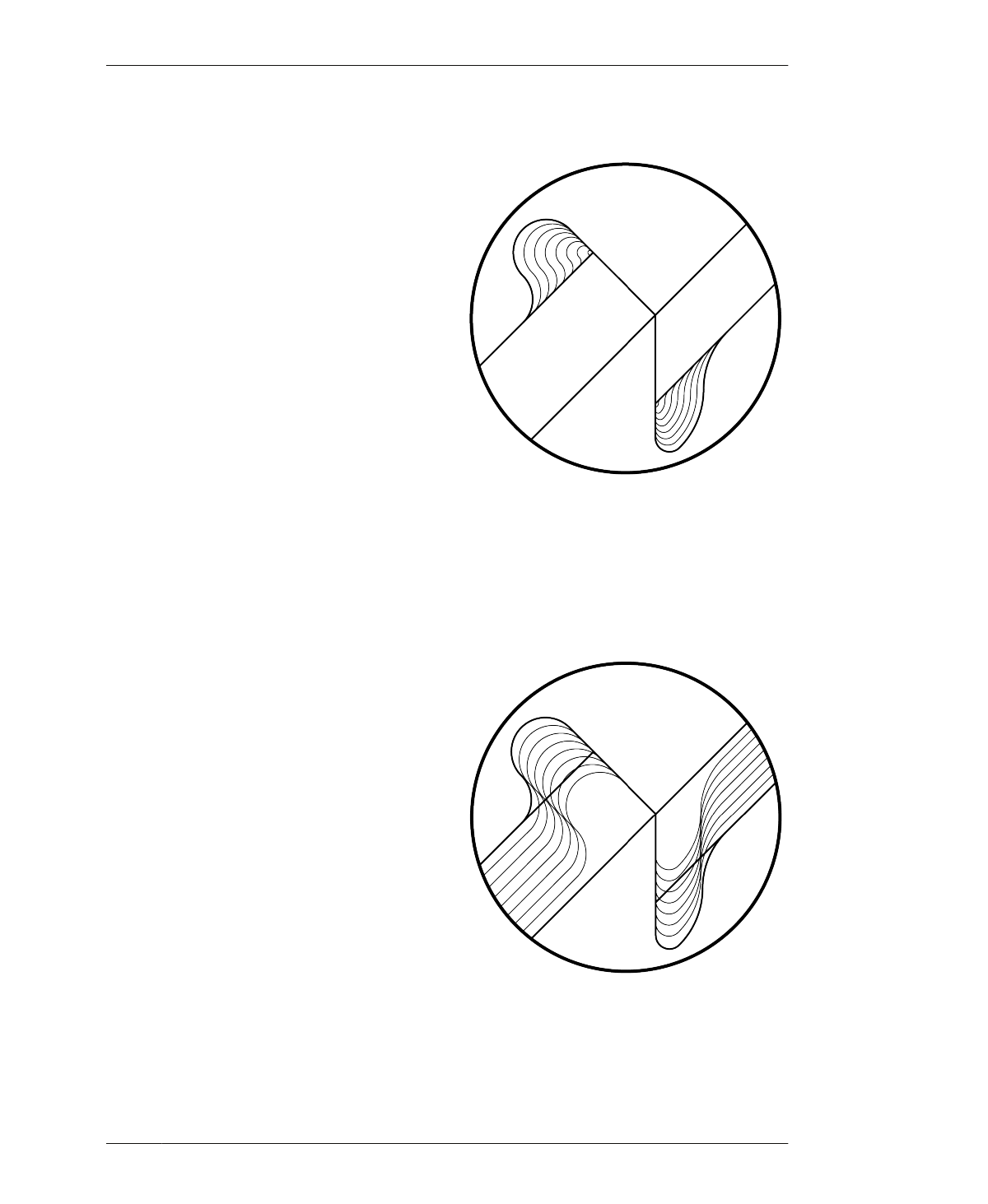

FIGURE 12-2

Tool diameter parame-

ter

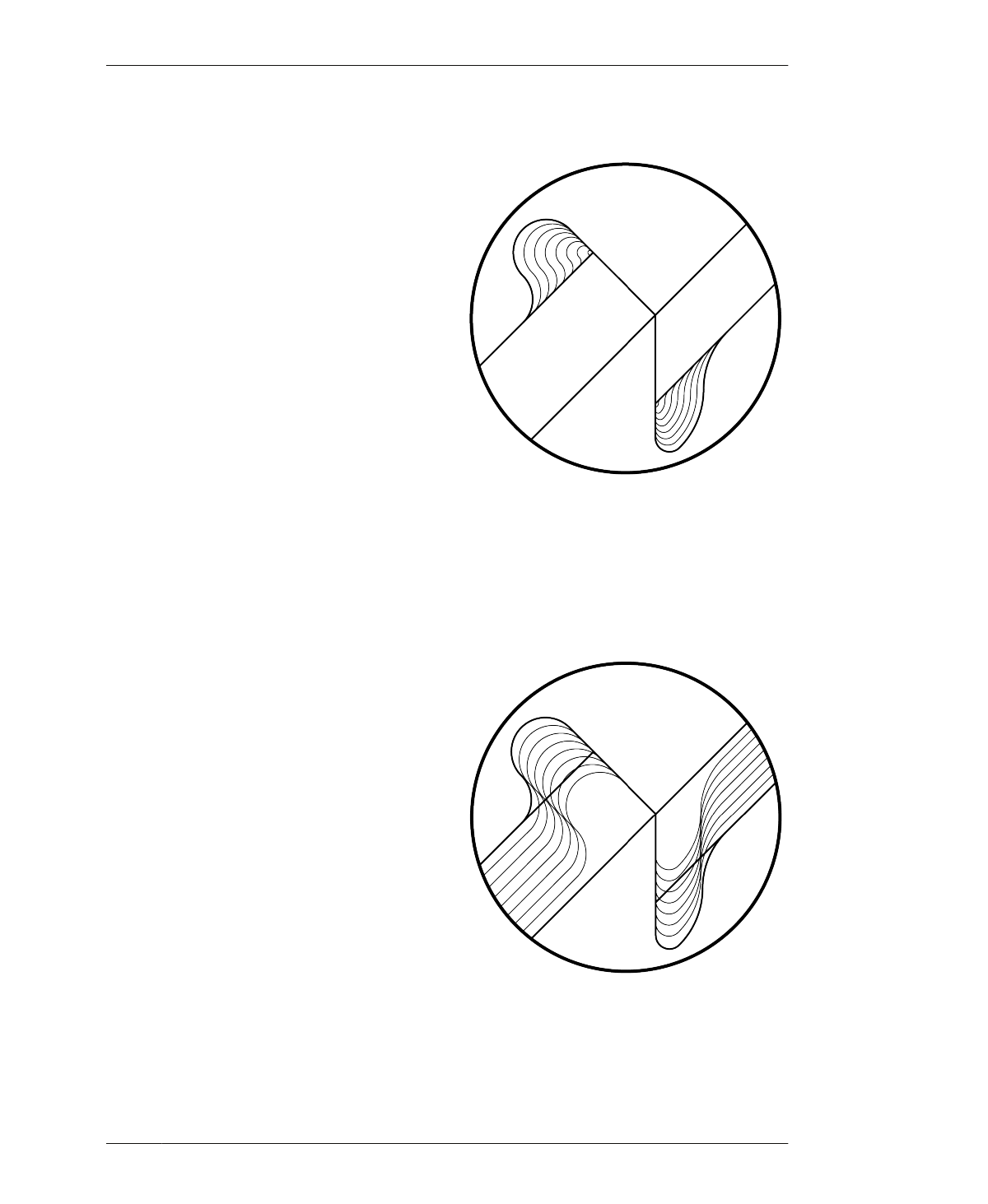

FIGURE 12-3

Material thickness

parameter

12/PARAMETRIC DESIGN

255