ATFAB’S PARAMETERS

ters, are the variables. Within a parametrically

defined table, for instance, a (mathematical)

function affiliates a supporting leg at each of

the four corners of a tabletop, while allowing

the table a variable length, width, and height.

Parametrically transforming this table changes

its overall dimensions, without affecting the

fundamental characteristics of four legs that

support a tabletop.

If you elongated either the 5-30 Minute Chair or

the 90-Minute Lounge Chair within the CAD file

in Part III, you were manually performing a

parametric operation. You adjusted the variable

width, within a function that preserved the rela-

tionship between the sides, legs, feet, fasten-

ers, and joinery.

A parametric definition is a specific operation

that transforms parts or adjusts attributes of a

digital model. By developing such operations in

the process of designing, a designer can make

an object and its operations inextricable.

For AtFAB, we designed parametric definitions

to yield a range of outcomes that are apprecia-

bly different and relevant. For all pieces, and in

the apps that accompany this chapter, we pro-

vide operations for adjusting material thick-

ness, sniglet diameter, and fastener diameter,

as well as for transforming a piece in either

shape, module, or dimension.

Some CAD software programs offer parametric

tools, which enable you to transform particular

physical attributes of an object. Though para-

metric modeling software enables you to assign

modifiable attributes to your model, the soft-

ware does not do all of the work for you. You

still need to do the intensive thinking to interre-

late elements within a design, and to determine

what is constant and what is variable. It’s not as

easy as many people think; it’s a lot of extra

work to design parametrically, but the implica-

tions of this effort can be powerful. With a sin-

gle parametric digital model, you can produce a

range of versions, like a series of similar tables

or chairs with varying dimensions or attributes.

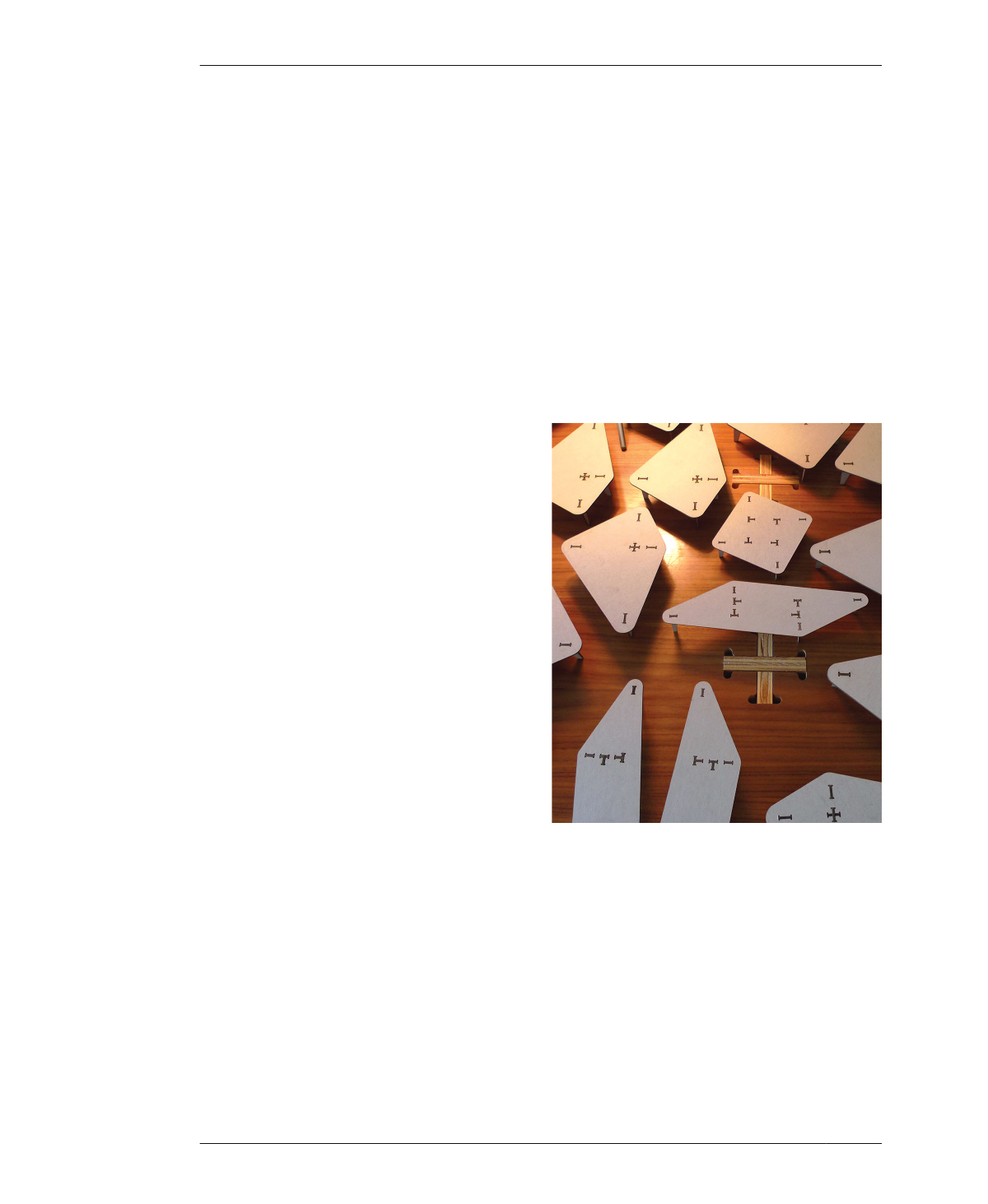

FIGURE 12-1 Prototypes of CIBi and CIBii versions

ATFAB’S PARAMETERS

Chapter 2 explained how AtFAB’s collection of

furniture pieces share a common language of

joinery, assemblies, and structures based on

the S/Z joint. As each AtFAB piece was devel-

oped, it was designed with parametric customi-

zation in mind. Thus, a finite collection of

furniture is actually a range of infinite versions.

Collectively, these parametric definitions give

each furniture piece a significant level of adapt-

ability for different materials, tools, and individ-

ual preferences. For distributed manufacturing,

explained in Chapter 1, the implications of this

versatility are vast. Makers anywhere can

download a file, tailoring the design to fit local

materials, available CNC tools, and specific

uses or needs.

254

DESIGN FOR CNC