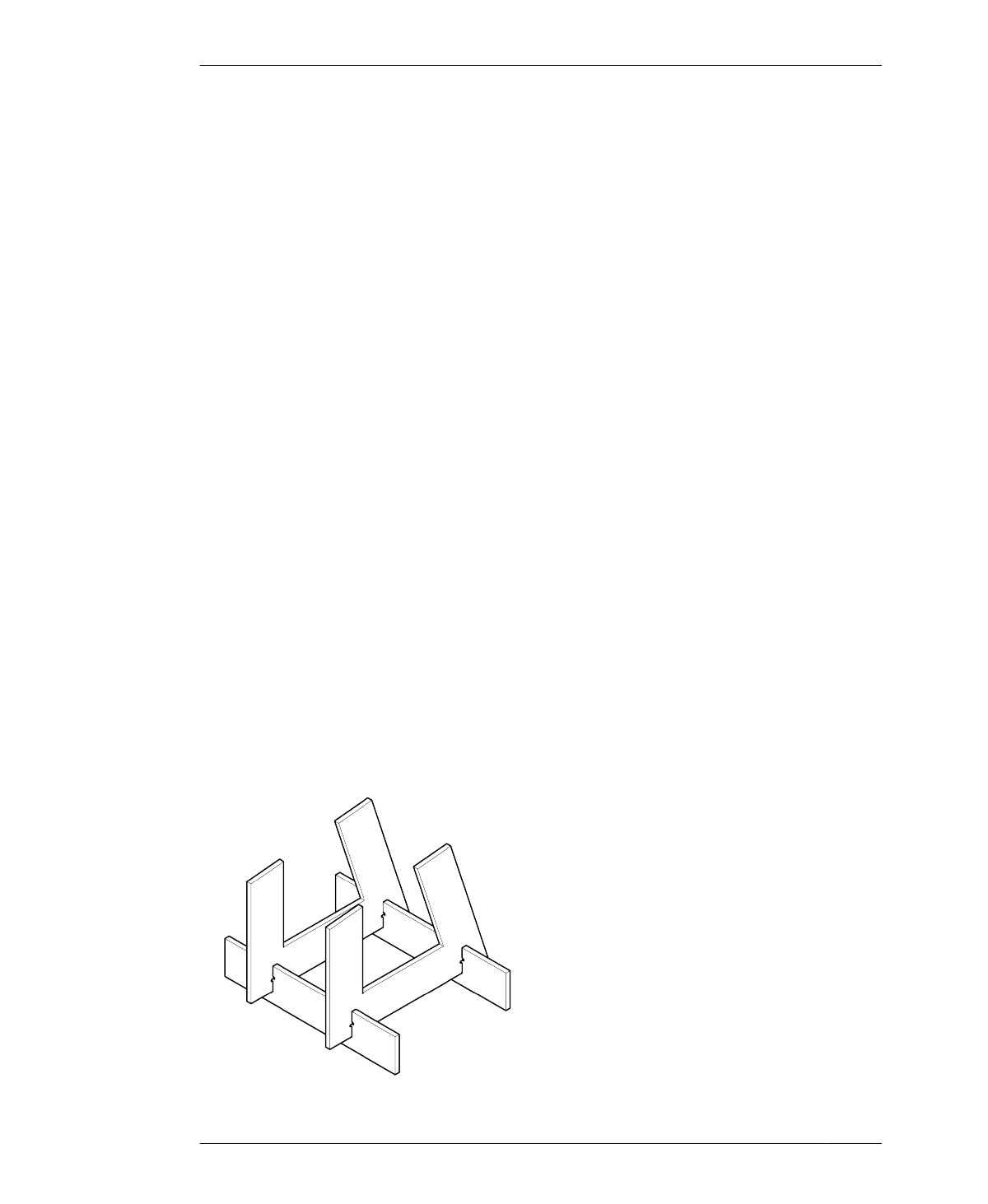

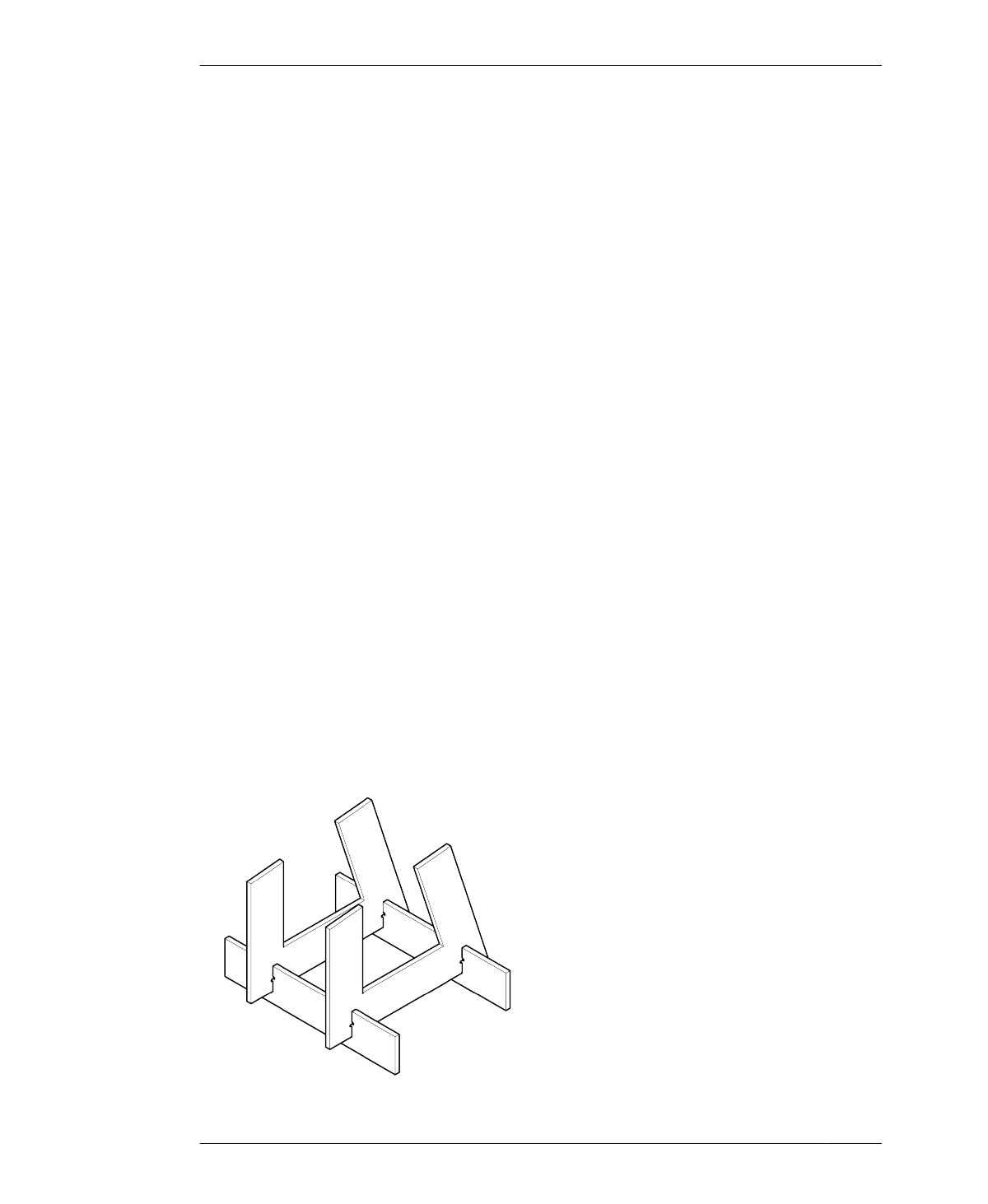

FIGURE 11-15

Assembled jig

ASSEMBLE

ASSEMBLE

Assembling the 90-Minute Lounge Chair

requires a jig, a friend, and a bit of patience.

USING THE JIG

Makers of all kinds make and use jigs to help

with different kinds of tasks during the fabrica-

tion process. For the Lounge Chair, we made a

jig to assist with the process of putting cut

parts together.

While it’s technically possible to do it on your

own, the jig and an extra set of hands helps to

keep multiple parts oriented and aligned simul-

taneously, which makes assembly go much

more smoothly. The jig parts, provided in

AtFAB_LNG_JIG.skp, may either be cut along-

side your lounge chair or separately from scrap

material.

01: Place a moving quilt, or other cover, to pro-

tect both your Lounge Chair parts and work

surface.

02: Put the jig together as shown, aligning it

along one end of your work surface.

03: Familiarize yourself with all of the parts,

arranging them so that each part is identifiable

and within easy reach. Note the front face of

each piece, if your material is sided. Keep blue

tape, hardware, and a drill close by.

The 90 Minute-Lounge Chair parts are assem-

bled with the chair upside down.

04: Place the Seat of the 90-Minute Lounge

Chair onto the jig, with the top of the Seat fac-

ing downward, and its rear tab projecting just

past the edge of the work surface. Hold the

Seat Back so it’s upside down, and hang it off

of the Seat. Bring the rear tab of the Seat

through the lower slot of the Seat Back. The

Seat Back is now hanging from the seat.

05: Holding the Arm part, with the finish side

facing toward the work surface, slip the U-

shaped Arm part over the Seat Back and

toward the Seat, rocking and shifting it into

place. As the Arm moves past the Seat, keep

working the Arm part into place until the tab at

the back of the Arm part fits through the sec-

ond slot in the Seat Back.

06: Hold the Front part with the finish side fac-

ing the front of the chair and the legs oriented

upward. Shift and nudge the part so that its tab

fits into the front slot of the Seat. The Arm part

can be rotated so that its front tabs fit into the

Front.

07: Select a Side part, turn it upside down with

pockets facing outward, and place the top tab

inside the arm. Rotate the Side into place,

aligning its slots with the tabs on the Seat and

Seat Back, and lock all parts into one another.

Similar to the previous step, the parts need to

be gently shifted and adjusted to ease each

Side into place. Follow the same process with

the second Side.

248

DESIGN FOR CNC