PARTIAL PROTOTPYE

POCKET CUTTING: TOP DOWN OR BOTTOM UP?

When you went through the Job Setup process

in VCarve, you set your Material Z to match

TMAX, and had an option to select the Z Zero, or

your z-axis origin, to either the surface of the

material or the surface of the machine bed.

While it’s standard practice to enter the top

surface of the material, there are occasions for

aligning the Z Zero to the deck.

When your design calls for a specific pocket

depth, but your TMAX varies by 5%–10%, you’ll

get different results depending upon whether

you zero to your deck, or you zero to the top of

your material. By zeroing to the deck you are

relying on a fixed point; by zeroing to the top of

your material, you are zeroing to a variable.

While this might not matter on all jobs, the

smaller the pieces you are milling, the more sig-

nificant the risk.

If you’re using ¾″ material and you zero to the

deck, you’ll be sure to have 3⁄8” of material

remaining from the bottom of your pocket to

the top of the deck, no matter what. If you zero

to the top of the material, your pocket will be

3⁄8” from the point to which you zeroed your end

mill, meaning that your pocket depth will vary

across the sheet by the same amount of fluctu-

ation that exists in the sheet.

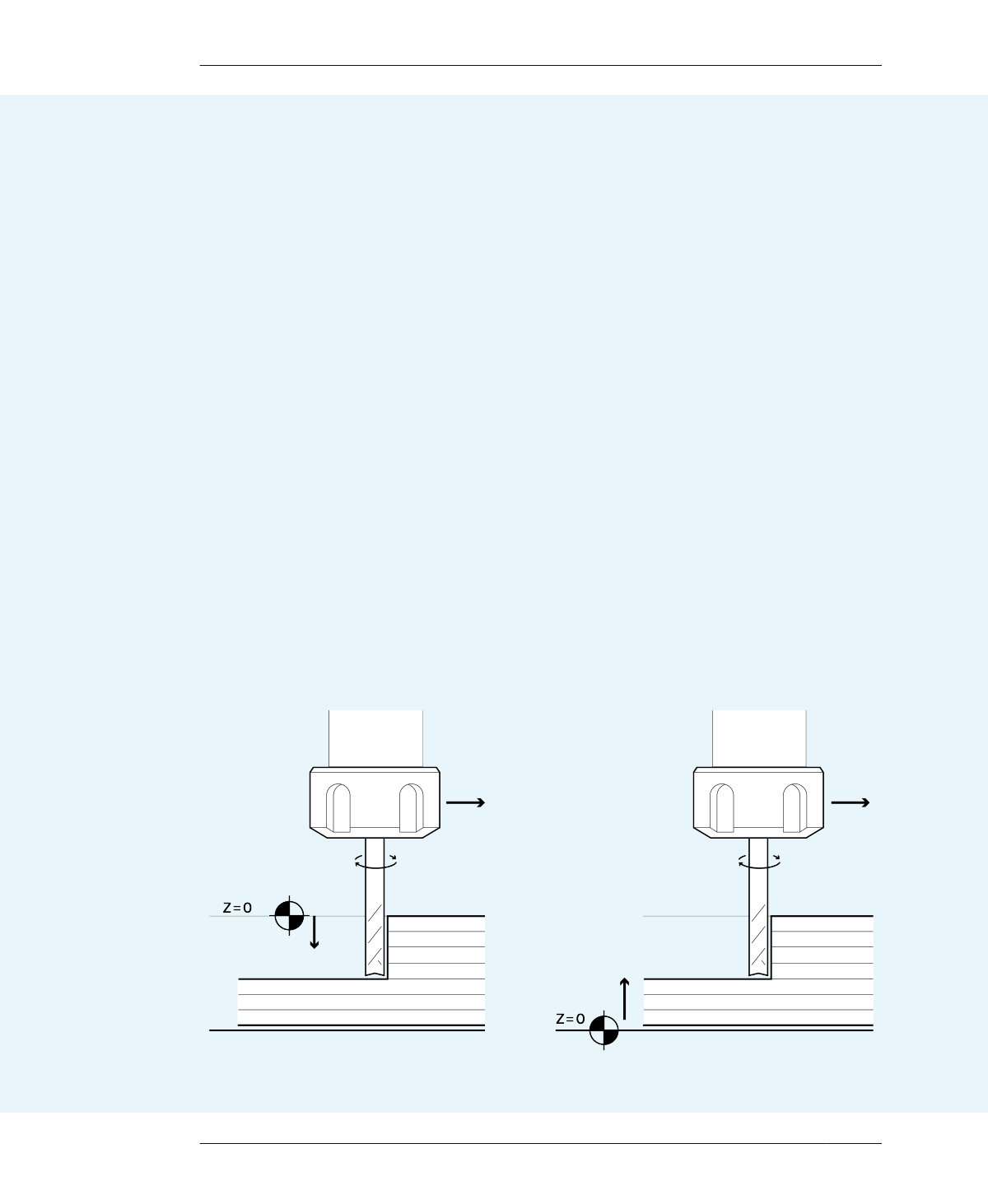

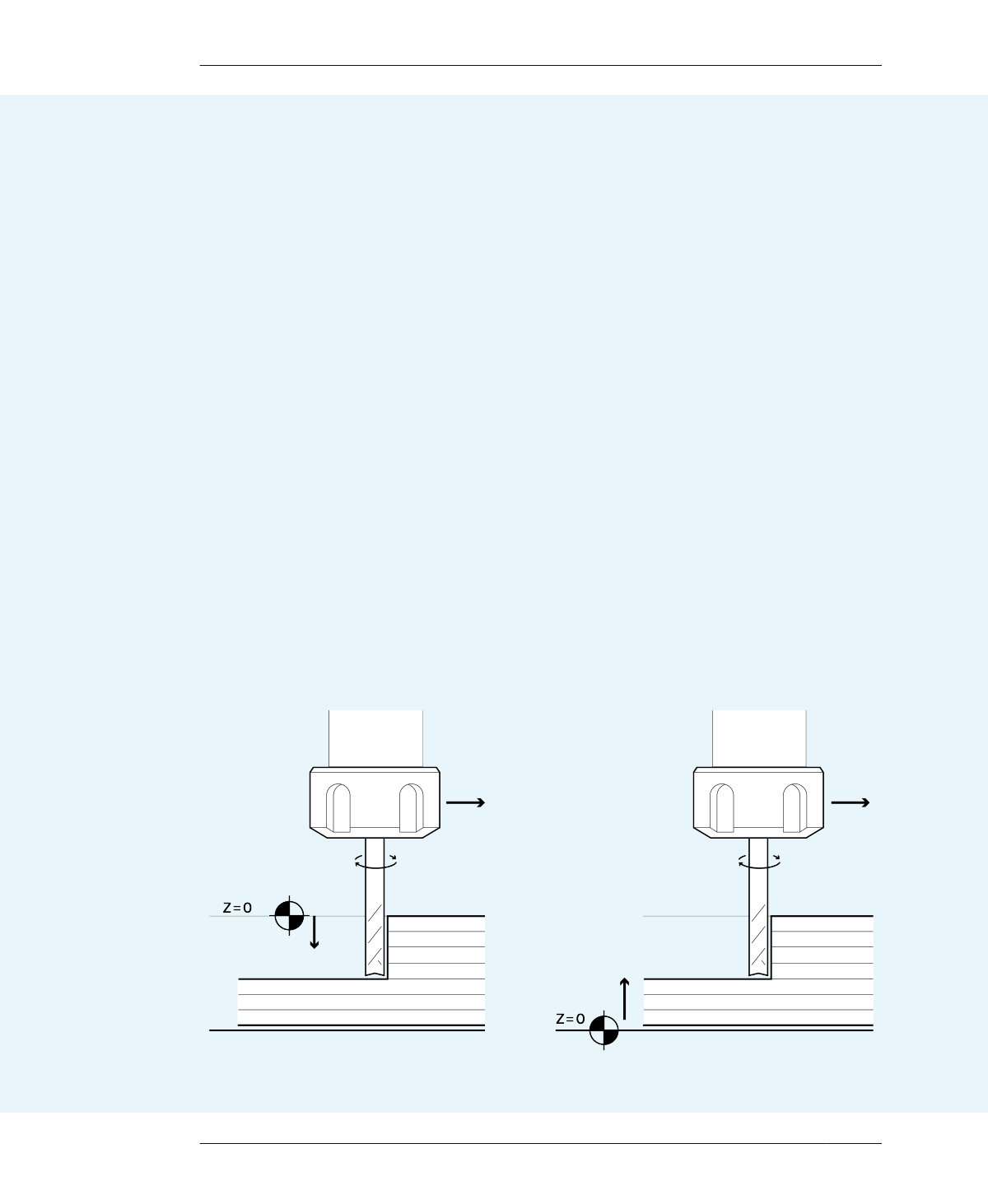

FIGURE 11-11

Zeroing the z-axis to

the top (left) and bot-

tom (right)

244

DESIGN FOR CNC